|

|

|

#401 |

|

Less usage=Cheaper bills

Join Date: Nov 2010

Location: Minneapolis, MN

Posts: 940

Thanks: 41

Thanked 117 Times in 91 Posts

|

I have no clue, mine was just the rubber that comes attached to the lineset, its all there inside the house but has mostly shed off from the siding to the condenser. I was just at the hardware store and saw a 4 foot section for $2. I figure I'll be there between now and when I turn the A/C on so I didn't buy it, I looked for some sort of insulating tape and didn't find anything. I found some decent looking fairly thin R3 ductwork insulation that I would have bought if it wasn't 12' long and 15" wide and $22, I'd need something cheaper and will probably buy rigid board of some sort and attach that.

|

|

|

|

|

|

#402 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 724 Times in 534 Posts

|

Quote:

Here's some stuff that's pretty close to what I used. As I recall, my line-set was 15' and I ended up using two rolls to do the whole job. When you wrap, don't pull the tape too tight as that will reduce the thickness. Regards, -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#403 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Pinpointed the pinhole in the leaky outdoor unit.

It was nice and warm in the garage today, so I popped the covers of the leaker, pulled out the thermistor, and did the nitrogen soap bubble thing.. Here's the Dental view of the leak location (under the bubble foam).  As soon as the soap was bushed on, I could see a tiny stream of little micro droplets (or micro bubbles?) spraying out from between the tubes. Looking down (Started reaching inside with the camera).  Close up of the silver solder (soap wiped away).  That does not appear to be a Stress point. I think maybe too much heat was applied when the little tube was soldered on. When the parts were cherry red, the clamp used to hold the parts together may have crushed the short tube into the compressor output tube.?. Now that I know where the leak is, I can figure out how to get it repaired. I think that little short tube (thermistor holder) needs to be removed. Then, the area where it was bonded, needs to be flowed over with silver solder. I'm kinda wondering about flooding the inside of the system with nitrogen while soldering, since the gas might exhaust out the leak hole, pushing any silver-solder out..  I guess the small tube with need to be opened, to allow the gas to flow out, under minimal pressure. I just hope there aren't too many restrictions to the flow, so pressure isn't going to screw up the soldering job.. |

|

|

|

|

|

#404 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Just added up the last 12 months of KW hours. We used 7,636 kWh.

Paying about .21 cents per, the cost is about $1,604 USD per year/ $133.63 per month (on average). Using 20.92 kWh per day on average. IIRC, before we got the Sanyo, we used about 500 kWh per month (ave) 6,000 kWh per year. So the Sanyo is adding about 1636 kWh ($343.56) to our yearly cost. LOL! that comes out to less than one buck a day.. Or, $28.63 additional cost per month. We pay $48 to $60 per month to go Candle Pin bowling!!  |

|

|

|

|

|

#405 | |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Quote:

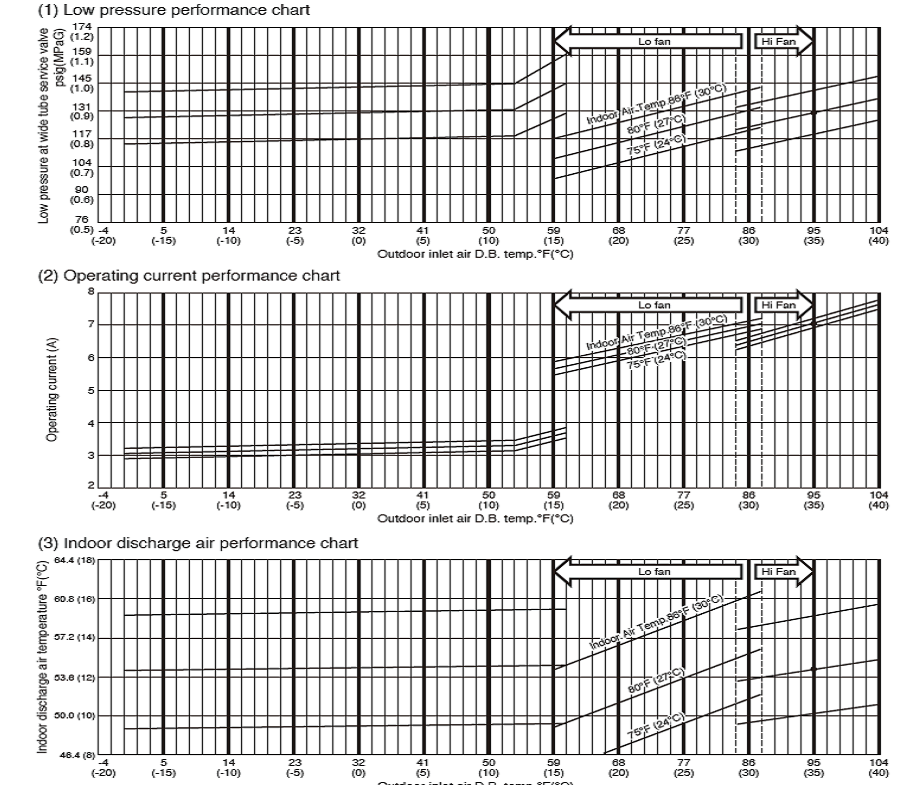

Today (July 17,2011), it's been sitting at 90F for hours.. So, looking at the chart below, I figured about 117 PSI would be on the service port. (w/75f indoors running 400 to 1400w). When first checked, in low power mode (400-440w), it read 165 PSI. Which seems pretty high to me. When in idle mode, it read 210 PSI. When I called for more cooling, went out and watched it, it dipped to 100, then climbed back up to 130-135 PSI, while using 1220 watts. That seemed pretty ball park. After a while, it settled at 145 PSI @ 1030w. So, I called for another degC of cooling and got 125 PSI @ 1500w. Pretty close.?. Then, I wanted to see if it would get down lower with more power, so I asked for another degC and the 8A auto-breaker cut the power for a second, causing a reset. (It must have peaked pretty quickly). After the pwr reset, 800 to 1000w showed 150 PSI. The last long steady run was at 1100w @ 145 PSI. I'm not sure what "Hi Fan" on the chart means, but the outdoor fan was running at ~50% to 80% max speed during measurements. So, when I took the winter pressure, it seemed low to me, now that I've done the summer measurement, it seems high..  What do you guys think? Just leave it alone and go watch TV? Thanks for any comments. Rich PS: I forgot to post the cooling chart!  Last edited by Xringer; 08-14-11 at 05:44 PM.. Reason: cooling chart added |

|

|

|

|

|

|

#406 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

After adding the Low Pressure Performance chart to my last post, it makes a little more sense.

The winter pressure test looked too low, and the summer measurement, is too high.. I'm at a loss here. Anyone have any ideas why this is occurring? The Sanyo is still working the same as it ever was. Heating and cooling is great. Thanks, Rich |

|

|

|

|

|

#407 |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Arizona

Posts: 145

Thanks: 0

Thanked 2 Times in 2 Posts

|

ringer,

Been following your Sanyo journey. Your working on some black magic stuff. Would like to know the real world freon stuff. I've not started on mine yet. Staying out of the hot garage. Have a couple projects started. Power tube bender bender and a plasma cnc table build .

__________________

Vern To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#408 |

|

Apprentice EcoRenovator

Join Date: Mar 2011

Location: SE Wisconin

Posts: 107

Thanks: 3

Thanked 11 Times in 9 Posts

|

Xringer, any progress on repairing the old unit so it can be used for testing with alternative uses? Another thought, could a normal digital thermostat be wired to the Sanyo to control in instead of the Indoor unit?

Random aside, I wonder why no minisplit maker has produced a unit for use with regular split HVAC systems. They could probably just specify a matched indoor coil made by a non-oem company if they didn't want the added trouble of designing and manuf. a new indoor coil. You could have the efficiency of a minisplit(provided it was matched with a Variable speed blower equipped furnace) with the aesthetics and common-ness of a regular split HVAC system. Adam Adam |

|

|

|

|

|

#409 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

I have been so busy with all sorts of stuff this summer, (including long bike rides)

that I have not even looked at that project. Yesterday, I posted about the decision I will have to make, once the unit is repaired. http://ecorenovator.org/forum/geothe...t-pumps-7.html Before the inverter units came along, the main reasons for mini-split efficiency was the fact it was duct-less. No duct-work losses. Connecting a unit like my spare 2-ton to an older ducted 3-speed central air system, might not be too bad, depending on the duct insulation and tightness of the house etc. I'm really tempted to use my spare Sanyo for hot-water. BUT, buying another indoor unit isn't real expensive, and a sure thing to make my wife happy. She would just love to have a nice warm den during the dead of winter.. It would also be a back-up for the main Sanyo, since it could also heat or cool most of the living area. |

|

|

|

|

|

#410 | |||

|

Apprentice EcoRenovator

Join Date: Mar 2011

Location: SE Wisconin

Posts: 107

Thanks: 3

Thanked 11 Times in 9 Posts

|

Quote:

And ahh the great decision. Can you run that unit on R-290? I thought those Sanyo's were R-410a units, which has a different P-T curve and uses non-compatible oil. Would this not cause running problems? Quote:

Quote:

With a second minisplit in the den running, I'd bet there are verrry few times you'd need the oil. Two running in really cold weather even at lower outputs might combined be enough to keep you warm? With a second minisplit in the den running, I'd bet there are verrry few times you'd need the oil. Two running in really cold weather even at lower outputs might combined be enough to keep you warm?If you really wanted to get fancy here, I wonder if you could do both, heat water and run an indoor unit. It could be fairly simple utilizing two reversing valves as three way valves to switch the flow between the exchanger an the indoor unit. Feeling up to a challenge?  Adam |

|||

|

|

|

|

| Tags |

| air conditioner, diy, heat pump |

|

|