|

|

|

#61 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Others have said, BBQ gas isn't real clean, and should be cleaned up before it goes into a system.

Maybe filters would work.. UNIVERSAL INLINE PROPANE FILTER HIGH CAPACITY | eBay EMERSON BI-DIRECTIONAL HEAT PUMP FILTER DRIER BFK-053S | eBay |

|

|

|

|

|

#62 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

This heat exchanger seems to be able to handle some pretty high pressures..

20 Plate Cu Brazed Heat Exchanger SS304 1" MPT B3-32 | eBay Design pressure 3.0 Mpa (435 psi) Test Pressure 4.5 Mpa (650 psi) Design Temperature -195°C to +220°C (-319°F to 430°F) Refrigeration Capacity 5-25KW (17,000-85,000 BTU/hour) 1" Male NPT Fittings Some guesses: The Dimensions of L: 11.25" W: 4.56" seem nice for being able to completely insulate the package, and keep it down to the breadbox size range. I might be able to keep the line-set down to a couple of feet. Meaning a pretty small amount of refrigerant would be needed.  Any anti-freeze electronics inside the package should be safe to use with propane, if open air-space inside the package was filled with closed cell insulation. Without air, the mixture would be too rich.  I guess the hot water pipe needs to be some kind of flexible hose or tubing that can handle up to 180 deg F. (Since my boiler can easily do that on oil). The danger factor here, seems like it would be a refrigerant leak, inside the exchanger, which would allow gas to get inside the 30 PSI boiler water jacket. HC-290 can get up to 380 PSI at 162F.. That could ruin my whole day. Besides using two of these exchangers, with another pump between them, I can't see anyway out of this problem. Maybe something less explosive? |

|

|

|

|

|

#63 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

There is a better version of the high pressure HX.. Using 1/2" copper sweat connections.

http://ecorenovator.org/forum/geothe...html#post15380 B3-32A 20 Plate Heat Exchanger [HX3220] | DudaDiesel Biodiesel Supplies  So, once I get the old OD Sanyo repaired, I will have to choose between hacking a hot water system, using a $175 HX, (I have the water pump etc) or buying another Sanyo indoor air handler. Sanyo KHS2472 Heat Pump Indoor Wall Unit Subtotal $329.23 Shipping $25.48 Tax $20.58 Total $375.29 That's only $200 more.. But, no hot water..  Last edited by Xringer; 09-24-11 at 09:56 PM.. |

|

|

|

|

|

#64 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

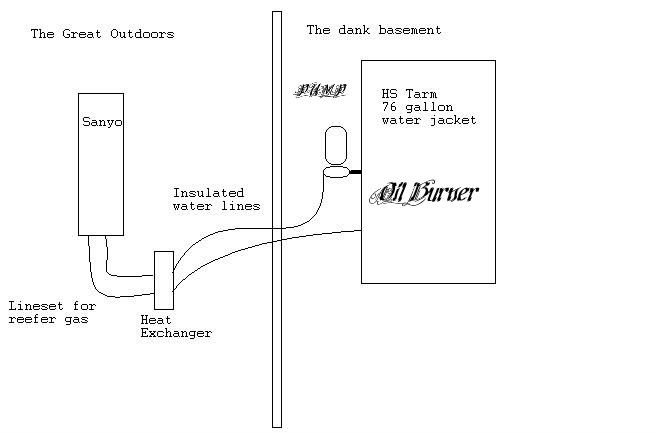

Here's a simple block diagram of the hot water idea.

The heat exchanger would get water from the boiler, via the circulation pump, whenever the boiler dropped below 120 degrees. Hopefully, the Sanyo (rated for 36,000 BTUh of heating) could warm the water up to 125 to 130 degrees before shutting off. I think the hack would be test-run mode, and manually controlling the Sanyo's 4 way valve (in case I wanted to defrost the outdoor coil). To pursue this scheme, I would have to test the unit (after repairing it), to see if the T-Run mode would actually work well enough to be useful. Maybe, I could just use a primitive coil-in-a-bucket of water to test the idea.. If the HX failed, high pressure gas could get inside the water line, and the HS Tarm would not be able to take the pressure..  |

|

|

|

|

|

#65 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

-AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#66 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Due to 'code', my boiler water jacket has a T&P safety valve on it. So, over pressure is going to vent down a few feet onto the basement floor. The T&Ps are old and need replacement, so maybe directing the over-heat / over-pressure venting outdoors might be okay.. I'm not real sure if this idea would meet local code, but it sounds like something to think about.. I'm not sure if installing any kind of pressure relief outdoors would work very well, due to the effects of low temperatures. (I don't want to put glycol in the water jacket, unless I have to). In case of a long term power failure, very low temperatures could be the cause of an HX failure.. Last edited by Xringer; 08-28-11 at 07:57 PM.. Reason: more.. |

|

|

|

|

|

#67 |

|

Helper EcoRenovator

Join Date: Mar 2011

Location: Sarnia, Ontario, Canada

Posts: 91

Thanks: 8

Thanked 2 Times in 2 Posts

|

It occurred to me that if the heat pump was located in a modified green house, raised off the ground for ventilation, there might be increased efficiencies. The bottom of the "green house" would be open to the outside air for ventilation of leaking gases. Inside the "green house" the heat pump could draw it's air from higher up where there is warmer air. And the expelled air could be directed to circulate for reheating. (think of solar heater)

|

|

|

|

|

|

#68 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

"the expelled air could be directed to circulate for reheating."..

That sounds a bit like the 'trapped air syndrome', where cold air exhaust, that is cooler than the local outdoor air, is sucked into the coils again.. But it has less heat to give up..  I like the idea of a green house. A nice long E-W green house, (rectangular) with the Sanyo sitting up against the narrow East wall, sucking all the air out of the green house and blowing into the great outdoors. The air-intake would at the other end of the building.  Part two: Insulate the floor from the cold ground, double pane the southern side, black-out & insulate the northern side.. And for good measure, line the north wall with water-glycol tanks? (Sun exposed of course). Yeah, instead of a green house, it would really be a big long solar heat collector..  |

|

|

|

|

|

#69 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

My ravings above, shown here:

The heat exchanger would get water from the boiler, via the circulation pump, whenever the boiler dropped below 120 degrees. Hopefully, the Sanyo (rated for 36,000 BTUh of heating) could warm the water up to 125 to 130 degrees before shutting off. Have got me wondering about just how hot the HX exit water is going to be..?. When I'm warming the house in winter, the Indoor coil does get up to about 120F..  I'm wondering if having a short line set to the HX, with less loss, would allow for temperatures of 125-130F?? Even higher would be nice, for some space heating and hot water.. I wonder what the upper limit is..?. Cheers, Rich |

|

|

|

|

|

#70 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

The repair on the old Sanyo outdoor unit is going well so far..

http://ecorenovator.org/forum/geothe...r-project.html And, I think maybe 123 to 140 deg F out of the Sanyo is a distinct possibility. http://ecorenovator.org/forum/geothe...html#post15876 Since I don't like to deal with really hot water, that temperature range would be very acceptable to me. I plan to test the Sanyo soon. To make sure there wasn't any compressor damage. If compressor function testing goes well, I will try to determine if the T-Run test-mode (running w/o an indoor unit attached) would be feasible for a water-heating project. If it turned out to be possible (T-Run keeps the power use limited) and appears easy to implement, and if the small DIY HX looked promising, this would weigh on the side of doing the hot water project, instead of just buying and installing a new Sanyo indoor unit..   |

|

|

|

|

|

|