In part 4 of our series, AC Hacker had just found out he could weld plastic without too much trouble. He used a skillet on a stove, heated up two short pieces of tubing, and pushed them together forming what you see above. He noticed that the plastic started to melt right around 300°F (149°C). So, he figured he could think of some way to create an inexpensive and more portable tool to do the same thing.

Not being too sure of the quality of the weld, AC Hacker took the piece he had welded up to the local machinist. There, they tried to tear the pipe apart. What they found out was that it tore everywhere else but the weld. So, the weld was in fact strong enough. After tossing ideas around with the machinist, AC Hacker decided to take the skillet to the band saw creating two rectangle pieces for his would be tool.

On his way home, AC Hacker stopped by the local Goodwill store to look for electric heating elements. This is an idea the machininst had offered. He found a nice small one in a mini-sandwhich maker. This small set of heaters would prove perfect for his tool.

With the heaters in hand, AC Hacker made a return trip to the machinist. Previously, the machinist had offered to mill slots in the skilletplates for the heater. So, that is exactly what he did.

To add temperature control to the new tool, AC Hacker used an electric skillet temperature control. This allows him to dial in whatever temperature he finds to work best for welding the plastic tubing.

The last step for the tool was to add some electrical insulation to prevent getting shocked while using it, and to adjust the temperature for the actual welding. Once the temperature was set, AC Hacker taped up the temperature dial so it would not accidently get changed.

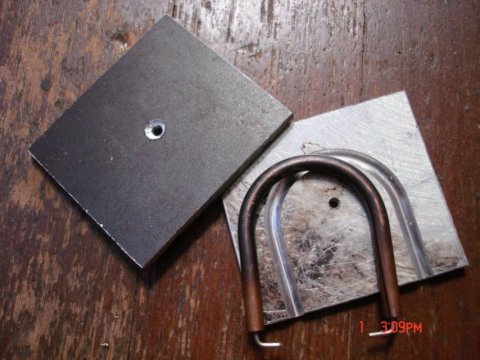

With the tool done, he needed a way to hold the pipes square to get a solid weld. The above is the welding jig that he came up with. After making it, he noted that such a nice setup is not absolutely needed and that one could easily make something out of wood that would work just as well.

With these new tools in hand, AC Hacker is setup to create the welds needed for the heat pump system.

For more details about the tools and project check out AC Hacker’s forum thread that tracks all of his progress.

Comments on this entry are closed.