|

|

|

|

|

#1 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Brazing copper seems to need very high temperatures..

What kind of rig would be good for small scale hacker apps? I like this one, ($320 +$26 shipping).  GENTEC Light- to Medium-Duty Cutting/Welding Kit, Model# KA-51-TCPW | Cutting, Heating + Welding Torches | Northern Tool + Equipment But, this one,  is only $60 at Home Depot.. Bernzomatic Multi-use Tote Torch - OX2550KC at The Home Depot I've read it's hard to get the right mix with these valves.. More Oxygen bottles are about $8 at Lowes, when in stock.. And, what is an "Air-Acetylene Torch"?? Sears: Online department store featuring appliances, tools, fitness equipment and more Thanks for your comments, Rich |

|

|

|

|

|

#2 |

|

Administrator

Join Date: Aug 2008

Location: Germantown, WI

Posts: 5,525

Thanks: 1,162

Thanked 374 Times in 305 Posts

|

Does map gas alone not get hot enough to braze for HVAC?

__________________

Current project - To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. & To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#3 |

|

Lurking Renovator

Join Date: Dec 2010

Location: Pittsburgh PA

Posts: 3

Thanks: 0

Thanked 0 Times in 0 Posts

|

Funny you should mention that.

A few years ago, this guy I knew (who I must emphasize IS NOT ME) got into home distilling. Now this means a lot of copper: a large-diameter, packed column for the vapor, and a smaller, jacketed one for the condensed goodies. For strength, he thought "silver solder/brazing" was the way to go. Using *just one* H-D mapp canister was unworkable on Cu of over 1/2" I.D. What DID work was duct-taping TWO bottles together, such that the flames pointed at the same general location. This could heat copper up to 2" I.D. to brazing temp, and probably could work on much bigger pieces. |

|

|

|

|

|

#4 |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Just when you thought it was safe to go outside...

I have a buddy that used a hand held spot welder to heat copper water pipe for soldering. I never heard of anybody doing that before, but he said it worked great for him. Faster than gas. -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

#5 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

I'm not sure. It might be borderline for larger than 1/2 copper lines.

I've used MAPP gas before, when installing hotwater solar using 95/5 solder (95 % TIN) on 3/4" copper pipes and fittings. But, after watching some videos of HVAC braze jobs, I can see the pipe and fittings glowing cherry red.. The filler metal used on a lot of those jobs, was 15% silver and 85% copper. (Very costly stuff). If I decide to DIY a heat exchanger, then it's doubtful MAPP alone would be the way to go.. |

|

|

|

|

|

#6 |

|

Lurking Renovator

Join Date: Jan 2011

Location: Indiana

Posts: 18

Thanks: 3

Thanked 1 Time in 1 Post

|

MAPP gas would be fine for 1/2" copper and borderline for 3/4" copper. I have generally use acetylene for up to 1" copper and silver soldered the joints.

|

|

|

|

|

|

#7 |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

HVAC, because of the incessant vibration and the relentless deep temperature-cycling really needs to be done with some kind of brazing rod. The trade seems to prefer 15% silver brazing rod. I'm doing ok with 5%, though the flow is maybe not so pretty.

HVAC is really a much more punishing environment than plumbing. Ironically, many of the HVAC guys I know talk about "soldering it up", but if questioned, will admit to brazing. -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

#8 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Found a brand name rig (I think) at:

Victor 0384-0936 Genuine Portable Torch Cutting Welding Some sticks on Ebay: HARRIS STAY-SILV 15 PHOS-COPPER SILVER BRAZING ALLOY - eBay (item 220782605610 end time May-18-11 10:14:36 PDT) Is Victor a good brand?? My few welder friends aren't giving me much information. They own the large (non-portable) gear, purchased used.. |

|

|

|

|

|

#9 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

I'm using just a MAPP gas torch, no oxygen. I have tried just propane and it just barely got to cherry red... very frustrating. When I switched to MAPP, it worked much better. You probably already have a propane torch, you might try getting a bottle of MAPP gas and running it that way. If it doesn't work, you have a spare bottle of MAPP gas. Tricky part is that the cherry-red temp is not so far from the slump temp of copper... so you don't want to go too hot. You may be right, straight MAPP gas might be borderline on larger tube like you have... you'll need to do some tests. Whatever setup you get, you should practice on something that is similar to the piece you're trying to braze. Do several tests... If you use up a whole bottle of gas doing tests, it is money well spent. > The filler metal used on a lot of those jobs, was 15% silver > and 85% copper. (Very costly stuff). You sure don't want to combine plumbing solder & brazing rod, they don't mix, very bad... I know... I tried it once... never again. I have had the best luck with SilPhos rod. It is self fluxing, flows very nicely. SilPhos is available in 5% silver (which I use) and 15% silver (which the HVAC trade seems to prefer). I haven't tried the 15% stuff because it's more expensive, but I assume it has a slightly lower melting point, which would be good for you. Before you braze, you should see if you have any positive pressure in your unit at all. If you don't it means that the R-410a has all leaked out, and you can assume that the unit has been"breathing" (my term) air and moisture in the meantime, so you should pump down and purge with inert gas a few times before you braze (principle of dilution). If you have any measurable pressure, you can assume you have enough R-410a to prevent "breathing" so you don't need to purge... but you may need to release some pressure... One of the warnings of running nitrogen (or other inert gas) while you braze is that if your nitrogen pressure is too high, you will get pin hole leaks. So this may be why you have the pinhole leak you have. When I braze, I run enough of my inert gas to purge the system, and I provide an escape for the gas, to which I attach a tube that I then insert a few inches into a jar of water. This way, I am assured that I have a continuous flow of purge gas AND I know that I am not building up any significant pressure. I adjust my purge gas flow rate so that I get a bubble every few seconds... so the flow rate is very, very low. You should ask at a welding shop what kind of rod you should use to fix an existing pinhole leak in a new unit, such as you have. They may even recommend 40% or 60% silver. (If you think 5% or 15% is expensive, wait til you price this stuff!!) BTW, my experience is that the guys who work the counters at welding supply shops (not the big box places) are VERY knowledgeable and helpful, and they understand that the good advice they have is part of their service. Very different from the HVAC trade... SInce you are not trying to join dissimilar metals, I wouldn't think you'd need flux. Since the price of rod has gone so high, some places sell what they call "job packs", which is less than a pound, and only has a few sticks (which may be all you'll ever need). You may also want to isolate the high temperature from the rest of your unit by wrapping wet rags around the tubing. You don't want to get too close to the joint you're working on, you'll make it too hard to heat up. -AC_Hacker P.S.: Be aware that brass fittings have a LOWER slump temp than copper...

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 05-17-11 at 10:38 AM.. |

|

|

|

|

|

|

#10 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

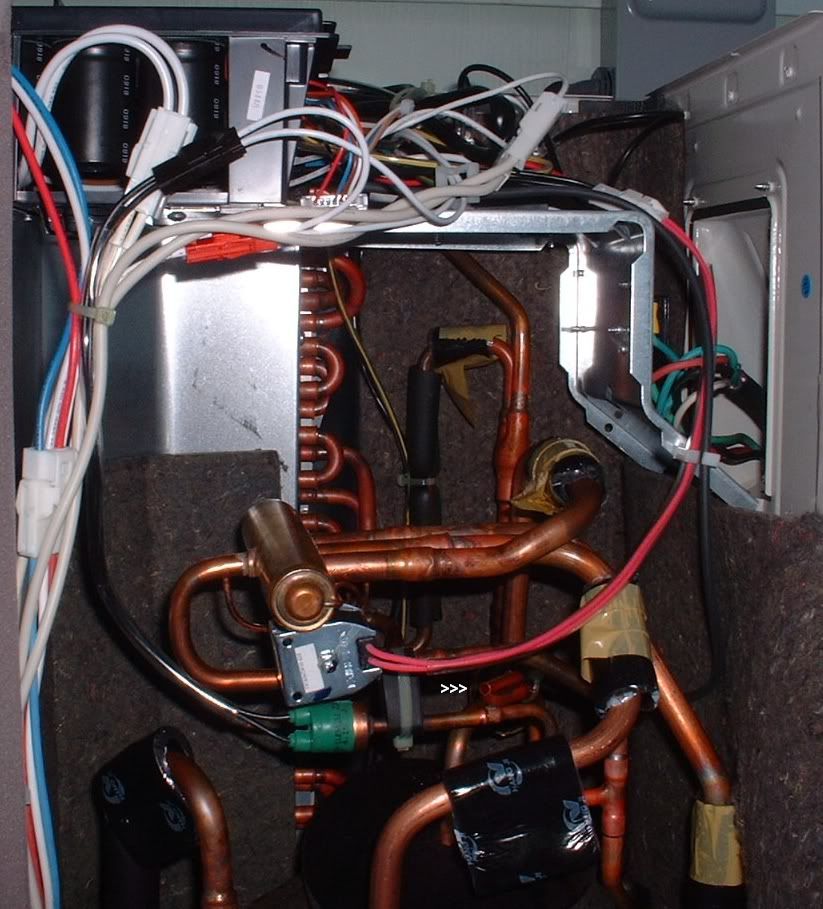

I have one of these http://www.bamboocraft.net/workshop/...eTorch-035.jpg

and a full bottle of MAPP gas. So, I can do some testing on scrap copper. I have to pull off a short section of tube, (it held the thermistor).   And then seal up the tiny pinhole right here:  Yes, "the unit has been"breathing". I assume it's full of moist air, that's being sucked in and out of the pinhole. This tube seems to be the output line of the compressor. Thanks for the water bubble tip on the nitrogen flow. I'm going to need it. Otherwise, the filler metal will just bubble right out. Due to the hole, I will not be able to vac the system at all. That will just pull more wet air into it. (I hope it stops raining some day).. I've heard about protecting parts from torch heat using wet strips of cotton from old t-shirts. I'm a bit familiar with process, due to all my DIY plumbing work.. I've watched some videos, and it seems like a really hot flame directly on that pin-hole area would get it cherry red very quickly. When the loose tube fell off, all I would need to do, is quickly melt some filler on top of the leak area.. But, looking at where the leak is located, I might not be able to reach in there with the torch.  Dang! Looking at this picture, I'm really thinking seriously of trying to find a welding shop that will braze this for me..  |

|

|

|

|

|

|