|

|

|

#1 |

|

Lurking Renovator

Join Date: Oct 2012

Location: London, Ontario

Posts: 1

Thanks: 0

Thanked 0 Times in 0 Posts

|

We have an old home with a floor that has no sub floor. We will be removing the plaster from the ceilings below the the second floor and already have access to the floors of the main floor from the cellar.

My question is, what is the best approach to installing pex tubing to heat these floors? Do we add a psuedo-subfloor in between the joists? |

|

|

|

|

|

#2 |

|

Administrator

Join Date: Aug 2008

Location: Germantown, WI

Posts: 5,525

Thanks: 1,162

Thanked 374 Times in 305 Posts

|

Hello Dumkat, welcome to the site!

Typically, stapling the tubing under the subfloor is not a very efficient way of heating. But, considering that you don't have a subfloor, the best option might just be to staple up pex tubing to the flooring with heat spreaders on them. You definitely want the tubes in good contact with the flooring so the heat can be transferred as good as possible. Do you have any pictures that might help us out?

__________________

Current project - To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. & To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#3 |

|

Master EcoRenovator

Join Date: Aug 2012

Location: Toronto

Posts: 958

Thanks: 40

Thanked 158 Times in 150 Posts

|

Get a thick aluminum heat pan from Rehau or Warmboard and have the spacing at most every 8". Then put 3.5" min of rockwool right up against it, then drywall. You can put a radiant barrier but it is of limited value.

|

|

|

|

|

|

#4 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 724 Times in 534 Posts

|

Quote:

I'm pretty sure Warmboard is fixed at 12" centers... (* Please let me know if I'm wrong. *) Roth Panel is spaced at 8", very good design. Best, -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#5 |

|

Lurking Renovator

Join Date: Oct 2012

Location: Upstate NY

Posts: 29

Thanks: 7

Thanked 2 Times in 1 Post

|

It's been my experience that there are much better ways to do this-especially in an older home - than using Pex. Pex itself is cheap but by the time your done with a mixing valve, clips, pans, manifolds, etc., it isn't inexpensive. IMHO, a much better way is to run fin tube(without enclosures) in the space between the floor joists. Even if you only do every other joist, you'll end up with a well heated floor. I divert a line off of a return before it goes back to the boiler and hit 4 or 5 joist spaces, then back to the boiler return line for that loop.

You're pulling heat from the return that would normally just dump back to the boiler. Your heating line should be leaving the boiler @ somewhere between 180*-190* and even if it's returning at 140*, that's better than you can do with Pex. I don't mean to offend anyone,especially in my first post here, but to me, Pex is glorified garden hose. |

|

|

|

|

|

#6 | |

|

Master EcoRenovator

Join Date: Aug 2012

Location: Toronto

Posts: 958

Thanks: 40

Thanked 158 Times in 150 Posts

|

Quote:

The goal with any heating system is to run as low temp as possible to be efficient. That said, I once did 20 houses using copper fins as you talk of, and they were up in Fort Francis, Ontario (-40C no problem) and run off a water heater. We placed them in the perimeter joist spaces and let them radiate up. They were low energy houses and I can't remember how many feet of fin tube there was per house but it worked (it was 20 years ago). PEX has its place which to me is in an embedded slab although I have used it for almost everything short of steam. Wirsbo tubing (Uponor now) used to talk about taking a piece of PEX (in the late 60s when it was developed) and which was placed in a steam heat test at steam pressure. Every month it was removed and measured and since that first test till the mid 90s when I talked to them, it had lost 5% of its wall thickness. This is an extreme example of how a good cross linked tubing can be so in a floor application at 100-120F..........no worries. The biggest issue is O2 barrier. |

|

|

|

|

|

|

#7 |

|

Lurking Renovator

Join Date: Oct 2012

Location: Upstate NY

Posts: 29

Thanks: 7

Thanked 2 Times in 1 Post

|

Your a much braver man than any I know if you'd use Pex in a steam application!

|

|

|

|

|

|

#8 |

|

Master EcoRenovator

Join Date: Aug 2012

Location: Toronto

Posts: 958

Thanks: 40

Thanked 158 Times in 150 Posts

|

|

|

|

|

|

|

#9 |

|

Lurking Renovator

Join Date: Oct 2012

Location: Upstate NY

Posts: 29

Thanks: 7

Thanked 2 Times in 1 Post

|

I would agree that in a slab, it could work fine. I just think that, in the case of the OP and an old home, there are much better and cost effective options. Look at the manufacturers temp ratings on the tubing. High efficiency isn't worth much if it isn't cost effective. The goal of any heating system is to keep you warm when it's cold. If it can be done cost effectively, so much the better!

Last edited by Minimac; 10-16-12 at 06:53 PM.. |

|

|

|

|

|

#10 |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 724 Times in 534 Posts

|

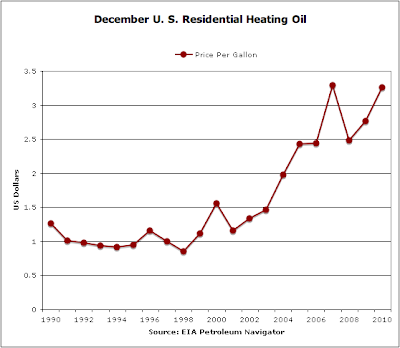

If you take a look at energy prices, and the steep increase in prices, it is clear that "cost effective" is a moving target, with a pretty short life.

A cost effective installation done today may not be so desirable in 10 years, when energy prices may have risen sharply.  The life of a car is fairly short, when compared to the life of a house. There are a large number of houses that were poorly insulated and used lower efficiency heating systems, even when better insulation and more efficient heating systems were available. But they were built to be "cost effective". At the time, it seemed prudent to build them that way, now they are a burden to heat. As a home owner, or a builder the "cost effective" measure needs to be observed to be competitive. However, some countries do not leave everything to the market place... Some of the Scandinavian countries, for instance have mandated insulation standards that are much higher than ours. If someone can't afford the standards, the government can help them. Many of the folks here at EcoRenovator volunteer to install much higher than standard (cost effective) levels of insulation, and heating systems that are more efficient than is 'reasonable'. You might even say that there is a friendly competition in that regard going on. Best, -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|