|

|

|

#1121 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

AC, did you think about using rain water (i guess you have plenty of it in winter time) somehow to add extra capacity to your ground loop? You could make under/above ground water collector and feed it with water from gutters. You could extract some heat from it and dump it after. This is just an idea.

I am thinking of combining heating of fresh air and extracting heat from exhaust air. I found coil that was used as a condenser on walk-in cooler (local metal recyclers is an excellent source of parts for DIY ). I am thinking to case it add drain and connect to exhaust duct. Refrigerant will go through this coil first (absorb some heat from exhaust air) then it will go through water coil. One of the problems I can see is it will increase refrigerant charge. My WSHP has already 21 oz of R22. When I add extra air coil I will need to add extra refrigerant. The unit is located indoor and using propane as a refrigerant can be dangerous. I am thinking of charging it with R22 first to determine the amount of refrigerant(r22a = R22/2.5) and if it is less then 350g (legal limit in Canada) , converting it to propane. |

|

|

|

|

|

#1122 | |||

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

But last winter, when I was running my little heat pump 24/7 for two months with no thermostat, I noticed that every time it rained hard, after a day or two, I would see an increase in heat output from my heat pump. So the heat that was embodied in the rain was carried into the ground and was available to my heat pump. In other words, mother nature had done the job of harvesting rain-heat for me. Running roof runoff over my loop field would help. Quote:

The DIY HRV is really interesting, with lots of interesting approaches disccussed. The direction I am personally most interested in is the use of an extraordinarily efficient passive heat exchanger core. The best examples I have seen are the mechanism used in Ko_deZ's Norwegian-built HRV and also the Fine Wire heat exchangers. In this post, Piwoslaw posted this diagram:  ...which is very interesting because it includes

Quote:

* * * By the way, there have been requests to see (lots of detailed photos) what kind of equipment you built for drilling your loop field. There are more than a few people who are 'stuck' at the point of fabricating a drilling rig. You could be of great assistance to them. They'd also really like to hear what your experience was in that regard, what problems you faced and how you overcame those problems. Best, -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|||

|

|

|

|

|

#1123 | |

|

Journeyman EcoRenovator

Join Date: Jan 2011

Location: Seattle

Posts: 326

Thanks: 109

Thanked 23 Times in 18 Posts

|

Quote:

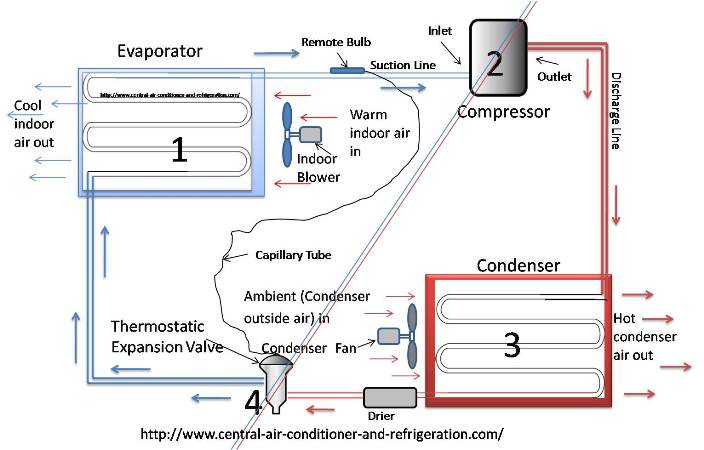

His system flowed this way: compressor, condenser, sightglass, receiver, pressure switch, filter dryer, txv, evaporator, txv bulb, sight glass, pressure regulator, pressure gauge, back to compressor. My understanding of a normal system with a cap tube would be this way: compressor, condenser, receiver, filter, sight glass, txv, evaporator, back to compressor. Why would he use the pressure valve? I have yet to learn why he would do the evaporator like he did. http://www.central-air-conditioner-a...e_Diagram1.jpg  My concern with your earlier statement about the difference in Cap tubes in a R22 vs. R22a system. I have a small R22 system that was evacuated and charged with R22a. It has not preformed as well as the original R22. The charge was measured according to the R22a equivalency charts supplied by the manufacturer. In fact, when it wasn't working correctly the first time, I gave it more refrigerant. Then to be sure I, removed it and started over with the advised amount. I am still learning. Would the Superheat of 20f still apply in a factory sealed system when using R22a? In otherwords, if we didn't know the factory specs (as any DIY would experience on hacking a system) would monitoring Superheat vs Subcooling be best? |

|

|

|

|

|

|

#1124 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

Your comments can be very discouraging to new-comers to HVAC hacking. Perhaps that is exactly what you have in mind. Do you have actual experience with re-purposing a R22 air conditioner to run on R290 or Bar-B-Que gas which is a blend of propane and iso-butane? I realize that you work in the industry, installing and maintaining HVAC machines, but this is a bit different. I say this because I have actually tried it and it not only works, but it works much better than I would have suspected. Also, randen tried the same thing. He also did some COP tests and the performance was quite respectable. He has reported on saving large amounts of money compared to his previous oil heat. Also Acuario did the same thing and he is heating his swimming pool, and now his house using this method, and he is saving a lot of money not having to burn oil for heat.. So, people who live in very different parts of the world are having similar successes when using this method. In other words, when you say that you can't switch a machine that was designed for R-22 over to Bar-B-Que gas or R-290, do you actually know what you are talking about? Do you really have actual experience in this matter? I do realize that a cap tube meant for R-22 is not perfectly sized for Bar-B-Que gas, and that the very best operation would result from exactly matching the cap tube to the new setup. I also realize that a TXV would allow a builder to precisely tweak the metering valve by simply turning a screw. But some new builders can't afford a TXV, and the prospect of incorporating a new, expensive valve might just be enough to prevent that new builder from ever attempting that first hack. But a hacked air conditioner that retains the original cap tube that was matched to the compressor can work, and can provide enough useful functionality that a builder might advance on to more sophisticated components. If you know what the procedure for resizing a cap tube is, would you like to start a new thread on that topic? You might want to introduce our readers to cap tube sizing charts. You might also want to introduce readers to some of the free software that can be used for this purpose. It would be a welcome addition to our shared knowledge. -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 02-23-12 at 02:57 PM.. |

|

|

|

|

|

|

#1125 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

AC, I never wanted to discourage somebody to try DIY. I started DIY projects when I was 4-5 years old(that was not an ac hack

). ).But when people say or hear about DIY most of them think: "something useless that will never work properly". I do not like this and want my system be better then commercial ones. As you mentioned before to hack an ac you need to invest in tools. You can read how people charge ac without vacuum pump (just blow refrigerant and let it displace air), braze without nitrogen, use soft solder on ac tubing. I am always against things like this. I have one WSHP that is cap tube, I am converting it into 2 txv with external check valves. You can buy new small (1-1.5-2 ton) txv on Ebay for just 10-30 $. Cap tub is antique technology. I just wanted to repeat some cons of cap tube: 1. Critically charged system (critically means very critically. You just can not use amperemeter or thermometer or gauge set. You have to use them all at the same time. And every time you want to adjust superheat (which MUST BE 20F) you have to change cap tube size (make it longer or shorter or go with different size)) 2. System is VERY temperature sensitive. You MUST be in the range. 3. System is VERY load sensitive. If you want to add extra capacity to your evaporator or condenser you are in trouble. If you want to use water instead of air you are in trouble again. 4. System is refrigerant specific. It is like you take oil, water and kerosine and try to push them through the same tube. They all liquids but you will have very different results because this liquids have different properties. I have enough knowledge to service and design refrigeration systems. I finished full 2 year refrigeration course at British Columbia Institute of Technology. It is not just field training here and there, it is very fundamental course. I can be very useful when it comes to refrigeration and I am very open mind person but stubborn. If you guys think I am discouraging everybody I can just read and do my things myself. |

|

|

|

|

|

#1126 |

|

Helper EcoRenovator

Join Date: Oct 2011

Location: Canada

Posts: 91

Thanks: 6

Thanked 4 Times in 4 Posts

|

Hey Vlad, would you please post some more pictures of your drilling rig.

|

|

|

|

|

|

#1127 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

I am honored that you have posted to this thread. Your combination of training and experience is a very big plus. At the same time, the purpose of this thread is to encourage and assist people to try to make something useful out of "useless" or discarded or retired or maybe even new HVAC equipment. I know that there exists discouragement to undertake something like this, coming from many different sources, some external, some internal. For some people, maybe even you, the discouragement has very little effect. But for other people who may not begin with the same level of confidence or willpower, an inviting, helpful atmosphere is required. What I am saying is that I take a paternal interest in this discussion, and I want all of our readers to find this forum to be an interesting and encouraging place to draw information from and also an inviting place to share their successes and even their mis-steps. So, Vlad I am glad you are here, there's never been anyone here quite like you. I want to know a lot more about the projects you are doing. We're all learning here, myself included. -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 02-23-12 at 05:57 PM.. |

|

|

|

|

| The Following User Says Thank You to AC_Hacker For This Useful Post: | AlanE (02-23-12) |

|

|

#1128 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

I am not sure were to post about drilling. If somebody who knows this forum could give me some directions. I have good info and willing to share. Drilling is a whole another topic. If it does not exist may be we should start one.

|

|

|

|

|

|

#1129 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

The properties of R290 are so compatible with those of R22 that it's almost always a direct swap. Certainly charging critically charged systems can be a bit fussy, and yes superheat is important, but it's by no means impossible for the DIY hacker. |

|

|

|

|

|

|

#1130 | |

|

Helper EcoRenovator

Join Date: Oct 2011

Location: Canada

Posts: 91

Thanks: 6

Thanked 4 Times in 4 Posts

|

Quote:

Drilling and DIY geo go hand-in-hand just like DIY and hydronic flooring go hand-in-hand. AC Hacker has laid down a very good knowledge base and I'm keen to go but what I also feel I need is a better understanding of the engineering and fabrication of a drilling rig and that's where your experience has me most curious. I'm not going to embark on the grand journey and hand-dig like AC did  and you gave us tantalizing snippets of info on drilling and you'll recall that a lot of people chimed in saying how impressed they were with what you built but for guys like me there wasn't enough info and pictures. We've got 100+ pages on how to build a geo heat pump and lots of links to help us and that should the goal for drilling rigs. and you gave us tantalizing snippets of info on drilling and you'll recall that a lot of people chimed in saying how impressed they were with what you built but for guys like me there wasn't enough info and pictures. We've got 100+ pages on how to build a geo heat pump and lots of links to help us and that should the goal for drilling rigs. |

|

|

|

|

|

| Tags |

| air conditioner, diy, gshp, heat pump, homemade |

|

|