|

|

|

#1 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Since my basement gets kinda cold 50-60F during the winter, and up to the low 70s in the summer..

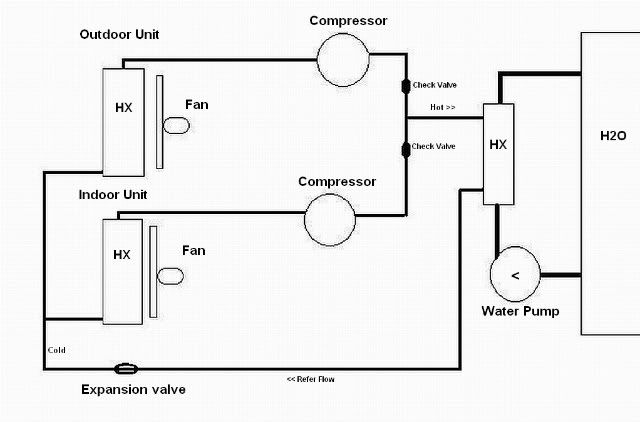

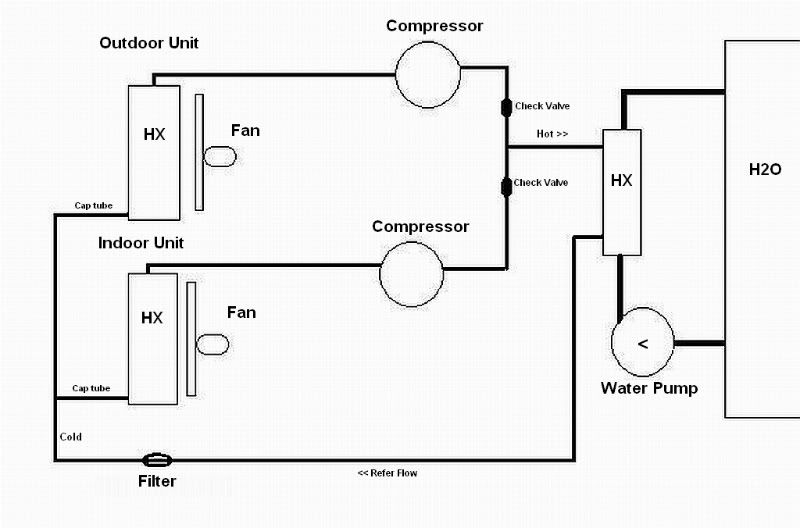

And the outdoor temperature can jump up above the 50-60 range, even during the heating season.. Does an ASHP hotwater heater need two coils and two compressors?  This might be a good app for the CAI controller board, since I would need to monitor a bunch of temperatures (5?) and control some individual motors. I'm considering this scheme because I happen to own a couple of small window AC units that aren't going to be very busy this summer..  Comments please:

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. Last edited by Xringer; 02-09-12 at 02:04 PM.. |

|

|

|

|

|

#2 |

|

Super Moderator

Join Date: May 2009

Location: Warsaw, Poland

Posts: 961

Thanks: 188

Thanked 110 Times in 86 Posts

|

If you want a basic setup, then dual compressors and HXs are overkill. If you want the system to be more flexible, then you might want to try it, though it will be more complicated.

__________________

Ecorenovation - the bottomless piggy bank that tries to tame the energy hog. |

|

|

|

|

|

#3 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

I was thinking, that being able to select the warmest place to pump heat out of the air, would be a big advantage.

So having one HX outdoors and one in the basement would give me that choice. I don't want to have a single portable Evaporator HX, that I have to move outside during the summer, and back to the basement when it got cold.. It wouldn't be overly complicated to control an extra compressor, and it's free. Being able to run both compressors simultaneously during the summer, would be nice for recovery time. The indoor unit could also be used for de-humidifying the basement during midsummer. When I drew the diagram, I realized the similarity to a 2-zone mini-split system. I wonder if the those 2-zone cool-only units even use check-valves.?. Questions: Would this DHW heater need two expansion valves? What type of valve should be used?

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#4 |

|

Apprentice EcoRenovator

Join Date: Mar 2011

Location: SE Wisconin

Posts: 107

Thanks: 3

Thanked 11 Times in 9 Posts

|

Interesting concept! I think you'd definitely need a TXV for this. The operating pressures would surely change quite a bit depending on what's operating. Don't most 2-zone mini-splits have on compressor?

Adam |

|

|

|

|

|

#5 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

A single compressor should do it. If you're gonna hack your A/C's, you will need to have an Air-to-Refrigerant heat exchanger for the evaporator (your A/C has this, with a properly-sized cap-tube already attached), and a Refrigerant-to-Water exchanger for the condenser (you could make a tube-in-tube or get a brazed plate HX). You will also need a small circulation pump to pump water through the condenser HX. You could even keep the case and all, and just give your A/C a condenserectomy (newly minted word). That way you reduce your worries about hardware placement, etc. The guy that sold me the water heater heat pump ('hydronic' is his forum name) had some issues with where to put the in-flow into the tank. He tried taking cold from the bottom, running it into the top, he also tried the reverse, and he finally settled on an in-flow pipe that ran down from the top to about half way into the tank. You could search for what he wrote, or send him a private message for details... he thought it was important for best operation. You'll probably have some amount of frost build-up. Your A/C controller probably has a circuit for just this thing...maybe you can use it. You could also use the CAI board and experimentally derive a 'duty cycle' that would allow a lapse between on-cycles when the unit is running during the most frost-prone part of the year (whenever that is). I observed that a dehumidifier does this this kind of thing but it has some kind of a brain... but not very much of a brain. Of course you will also need an insulated tank for a reservoir. An electric water heater would do nicely for this. I'm looking to do the same project, and I'm looking for a 60 gallon one. I'm seeing them locally for $50 to $100. Since there's just your wife & yourself, you probably don't need super fast recovery time, so your smaller A/C would probably do it just fine. If it recovers too slow, hack the bigger one to replace. If you use a water heater, it already comes with a high-current thermostat, and the thermal mass of the water in the tank would assure you of no short-cycling. It will almost build itself! If you want to be super legal, you should check to see if your state requires double-wall HX on potable water. As always, take lots of pictures. Have fun! Regards, -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 02-11-12 at 04:44 PM.. |

|

|

|

|

|

|

#6 | |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Quote:

I was just looking at a three-zone Sanyo, and I see they have three Electronic Expansion Valves hanging off the manifold. http://sanyohvac.com/assets/document...SeriesRevB.pdf I assume their secondary function is to turn & off the different zones.

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

|

#7 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

AC, I want to have two separate Evaporators, one outside with the other in the basement.

So, in the Spring, when it's 67F outside, I can used the outdoor evap. When it drops to 40F out there, I can use the inside evap that has 60F air around it. It seems like using two compressors wouldn't make the system much more complicated.. I think the expansion valve(s) might be the hard part.. Maybe use the cap tubes like you said.. Put them after the 'T' connection.?. Seems like it would be simpler that way..   No refrigerant switching, just turn on the compressor in the warmer loop..  ~~~ Wow, Just saw these on Ebay and ordered them.. eBay - New & used electronics, cars, apparel, collectibles, sporting goods & more at low prices The also have other sizes, but I think these will fit in the ID of 1/4 OD tube.. Maybe..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. Last edited by Xringer; 02-11-12 at 06:13 PM.. |

|

|

|

|

|

#8 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

This looks like a good high pressure HX..

NEW Alfa Laval AC10-16 Stainless Brazed 16 Plate Heat Exchanger 650 PSI R410A | eBay http://www.alfalaval.com/solution-fi...ments/AC10.pdf Comments please:

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#9 |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Pressure looks good.

1/4" sweat fittings look good. Size looks smallish to me. This is a real bugger about ebay HXs. I really don't think any of these guys know how to size a brazed plate for refrigeration. When they say: "THE AC-10 HAS UP TO 5KW PERFORMANCE WITH R22 APPLICATIONS" (17,060 BTU) I think they're overstating the capacity. You should Google Brazed Plate heat exchanger sizing charts, and look for ones that stipulate R-22... They're out there. I tried my best to put some sizing info in the "manifesto" thread. That was what I used to do mine. Water to water DOES NOT equate to refrigerant-to-water...not close. There are even some online programs that can help. You want your HX somewhat larger than required... +50% is not a bad guess. You can run parallel HXs, serial, too for that matter. The 3/8"sweat fittings seem a bit small for your water flow. If you got this HX, you might braze your water connector to the outside of the sweat fitting. Price looks great. If you could find the same thing with NPT fittings, or barb fittings on the water side, it would be better. This guy has some similar HXs... see what you think. If you hover over the "more options" text, you get... well, more options. -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 02-11-12 at 07:49 PM.. |

|

|

|

|

|

#10 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

The size for the water is confusing.. In the pdf, it says:

Standard Connections Water/Brine side A21 3/4” Gas BSP, E21 3/4” NPT Refrigerant side G21 (ODS 18 mm), H26 (ODS 3/4”) H27 (ODS 3/8”), H24 (ODS 1/2”) On the Ebay page it says: **** HAS SOLDER / BRAZE CONNECTIONS OF .375 AND .255 INCH Not NPT*** That seems to be those two different sized refrigerant ports..  So this is the water side.. And those are 1/4:20 bolts in the middle.. Those holes look about like approx 0.375" ID to my eye..  A couple of months ago, I looked at a lot of those DudaDiesel HXs and found their best pressure unit was about 435 PSI.. I would not trust that with R410A.. (If that's what I had to use). This Alfa Laval AC10-16 HX has great pressure specs and it's not to costly.. Maybe one of these would work if the demand was kept under 5000 BTUs.?.

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

|