|

|

|

#11 |

|

Less usage=Cheaper bills

Join Date: Nov 2010

Location: Minneapolis, MN

Posts: 939

Thanks: 41

Thanked 116 Times in 90 Posts

|

I've noticed something with the super efficient 9k and 12k units from Fujitsu, Mitsubishi, and Panasonic. It might be the same with others too but I haven't been paying too much attention to the other brnads, but what, if anything is physically different with these units between the two sizes? The weight, size, and other specs including performance at the same output level for the ones that have detailed spec charts like the charts from Fujitsu and Panasonic service manuals seem to be a match with no noticeable margin.

It seems that in order to have efficiency at the same level of output to be so close that they are running the same compressors and maybe even the same condenser and evaporator coils in both units. The blower CFM doesn't match up(except for these Mitsu units where all are the exact same numbers except for the max CFM), so is it just a different blower and a different firmware board in the 9k unit that limits the output of these units and since they aren't running with as high of output they get better efficiency ratings? After Panasonic released their XE9PKUA and XE12PKUA models, I was thinking that if the unit never needed to run over 9k output that the electricity use would be substantially the same and that if I have any doubt about needing the added output(I actually do need the output as 12k will be deliberately undersized for my house but in case I wasn't sure) that I would just buy the 12k model. ..now I'm looking at this Mitsu since they are on top of the efficiency ladder. Does anyone else see it this way? Last edited by MN Renovator; 02-01-14 at 11:15 PM.. |

|

|

|

|

|

#12 |

|

Apprentice EcoRenovator

Join Date: Nov 2013

Location: Moore Oklahoma

Posts: 267

Thanks: 108

Thanked 23 Times in 21 Posts

|

I'm with you, I do think the coils are the same but the compressors are different. Note that each unit has a different minimum output. It would be interesting to see a parts list..

|

|

|

|

|

|

#13 |

|

Less usage=Cheaper bills

Join Date: Nov 2010

Location: Minneapolis, MN

Posts: 939

Thanks: 41

Thanked 116 Times in 90 Posts

|

The minimum output for the 9k and 12k Mitsubishi units are both 2800BTUhr. I do see the difference with the minimum heat output though. Not sure if parts lists are available for these, I haven't run into one but I'm interested too. One other thing that would drive me to the 12k even if I didn't need the output is the extra moisture removal .6 pints/hour versus 1.9 pints/hour. I'm assuming that's in dry mode with the blower running super slow and the compressor cranking along at enough speed to just avoid freezing the indoor coil.

Last edited by MN Renovator; 02-02-14 at 01:03 PM.. |

|

|

|

|

|

#14 |

|

Super Moderator

Join Date: Jun 2013

Location: SC

Posts: 2,923

Thanks: 172

Thanked 564 Times in 463 Posts

|

I was thinking the exact thing looking over lots of 9000 and 12000 but systems. This would keep their production line much simpler.

|

|

|

|

|

|

#15 |

|

Supreme EcoRenovator

|

I've been doing some research on this subject, and have found a few generalities. The units below a certain tonnage (around a ton and a half) use the exact same outdoor unit. The indoor units may or may not be the same. Some of the indoor units have different coils and blowers, some of them have the same coils and a different blower, and some of them are the same mechanically and have somehow been speed limited by firmware.

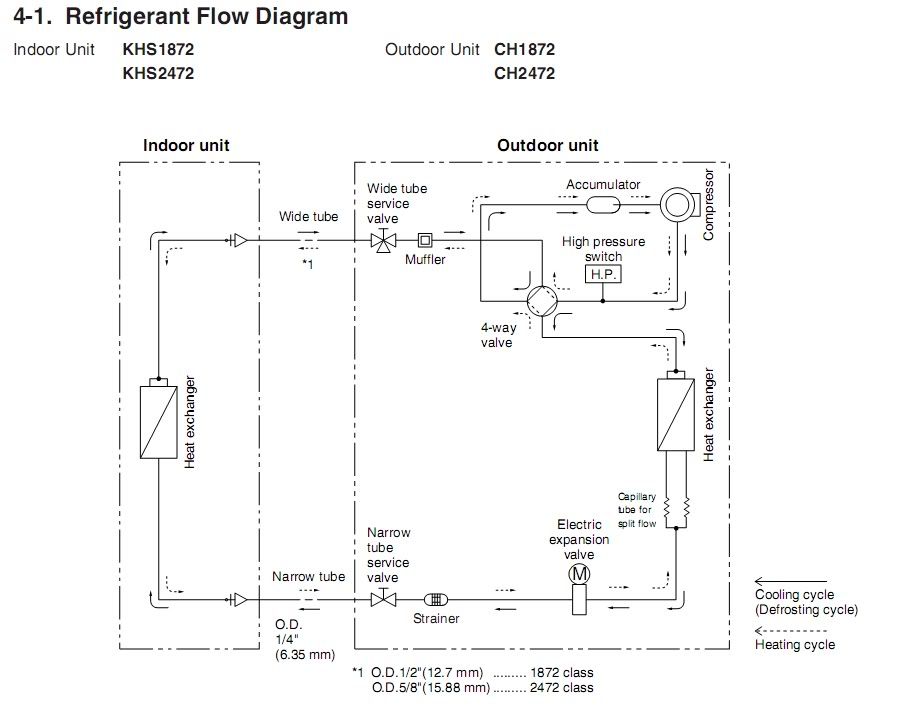

Up until recently, the outdoor units of these smaller units have been functionally very close to the same as each other. They have a variable-speed or inverter compressor in them, and are loaded to the gills with sensors. They have 2 cap tubes in series, one of them with a check valve shunt to bypass it during cooling mode. In heating mode, the extra bit of cap tube enables the units to operate into the sub-zero outdoor temperature range.  The compressor speed is controlled by the microprocessor in the outdoor unit, which senses indoor and outdoor ambient temperatures, suction and discharge temperatures, and at least outdoor heat exchanger temperature (positioned to sense frost/defrost). Some of the more elaborate units have pressure sensors in them also. Regardless of which indoor unit (or units, as some are mini-multi-splits) is connected to the outdoor unit, the compressor is throttled to maintain a certain set of parameters. If a smaller indoor unit is used, the outdoor unit runs at reduced capacity at a corresponding higher COP throughout its entire range. The last generation or two of cutting edge units have incorporated electronic expansion valves into the refrigeration circuit. The new Hyper-heat, Turbo-heat, Halcyon, and other pricey name brand units fall into this family. The EEV allows the manufacturer to control the behavior of the unit in a way not possible with traditional metering devices. Kind of like VTEC (or variable valve timing) in the automobile engine, the performance of the whole system can be skewed between multiple optimized modes.  These units, when graphed as to their output specs, overlay their data over the prior-mentioned generation of heat pumps of comparable capacity. Notice that this graph says nothing about efficiency.  The blue line represents a single cap-tube setup. The yellow line represents a dual cap-tube or TXV metered setup. The red line represents an EEV metered setup. Last edited by jeff5may; 02-02-14 at 05:15 PM.. Reason: pics |

|

|

|

| The Following User Says Thank You to jeff5may For This Useful Post: | AC_Hacker (02-04-14) |

|

|

#16 |

|

Apprentice EcoRenovator

Join Date: Nov 2013

Location: Moore Oklahoma

Posts: 267

Thanks: 108

Thanked 23 Times in 21 Posts

|

What I don't get is why do these "exotic" features have such a hefty price premium on conventional split systems?

|

|

|

|

|

|

#17 |

|

Super Moderator

Join Date: Jun 2013

Location: SC

Posts: 2,923

Thanks: 172

Thanked 564 Times in 463 Posts

|

|

|

|

|

|

|

#18 |

|

Apprentice EcoRenovator

Join Date: Nov 2013

Location: Moore Oklahoma

Posts: 267

Thanks: 108

Thanked 23 Times in 21 Posts

|

They could take an existing 3 phase unit and the variable speed electronics to it. I would think electronic boards are cheaper than the raw material used in 2 compressor multi-stage equipment. As manufacturers try reduce raw material used in their units, moving to electronic boards to improve SEER just makes sense.

|

|

|

|

|

|

#19 | |

|

Supreme EcoRenovator

|

Quote:

I believe probably the most expensive of these three is the new compressors. The newest units are using brushless DC permanent magnet motors, kind of like a computer fan on steroids. The rotors/scrolls have been optimized for low speed efficiency and oil delivery. All new tooling has been made to produce these compressors. Not to mention the switch to R410a pressure levels. In addition, they are charging premium prices for the new, higher pressure, totally redesigned heat exchangers. The new R410a unit have more copper in them, due to smaller diameter, more closely packed rows of tubing compared to the R22 units. Most all have variable speed blowers in them as well. The software built into the units is really what sets them apart from each other. With the increased operating window that R410a provides, the manufacturers with more concrete experience are putting their knowledge bases to good use. As with the Hyper-heat units, the big guys are listening to their customers' complaints, adding functions that change operating modes to correct previous units' deficiencies. The addition of multiple temperature and pressure sensors is allowing the computer scientists to assume control like never before. Since the controller has a better view of real-time conditions, better algorithms can be written to deal with a wider variety of solutions. Again, this really depends on the talent of the individuals writing the software. If you look at the specs, you can really tell who did their homework with these new systems. |

|

|

|

|

|

|

#20 |

|

Apprentice EcoRenovator

Join Date: Nov 2013

Location: Moore Oklahoma

Posts: 267

Thanks: 108

Thanked 23 Times in 21 Posts

|

All this same technology is available in mini-splits at a much lower cost.

|

|

|

|

|

|

|