|

|

|

#11 |

|

Supreme EcoRenovator

|

Some ice is not a bad thing. This means the refrigerant is evaporating below 0 degC. As long as airflow is not choked off, the outdoor unit will continue to gather heat quite well.

|

|

|

|

|

|

#12 |

|

Supreme EcoRenovator

|

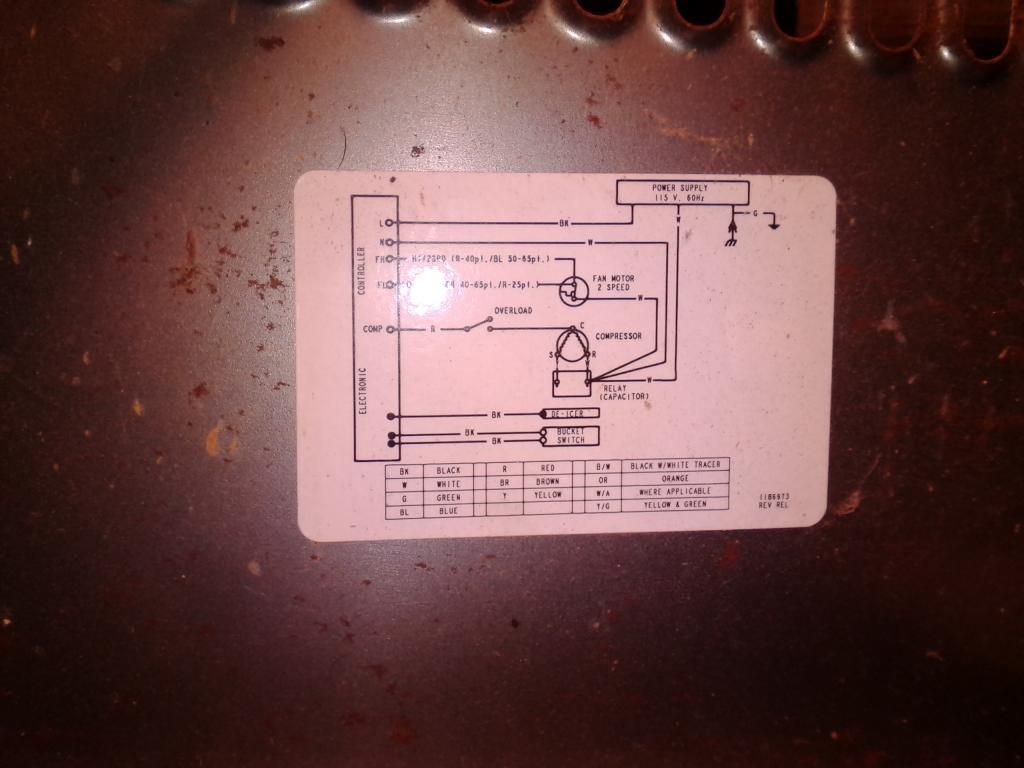

The next size up dehumidifiers look like this when new:

The one I modified to be a turbocharged electric heater looks like this now. If you look at the right side of the evaporator coil, you can see the little silver clip that holds the defrost thermistor against the pipe:  I had to remove all kinds of styrofoam from between the covers and the working parts to assume control of the airflow through the device. I then fabricated my own out of 3/4 inch polyiso "R-board". When run as a heat pump, the condenser had a miniature squirrel cage fan (robbed from a "space-saver" microwave that served as the fume extractor for the built in range hood) that blew air downward into the cavity and out the back (compressor) side of the unit. I had cut a piece to size that fit in between the heat exchangers to split the flow of air.  As you can see, this unit has undergone a few surgeries. It no longer has a capillary tube, a thermostatic expansion valve (TXV) has taken its place. This device allows the evaporator to extract much more heat than a cap tube. It also keeps the unit from frosting up when temperatures are not close to freezing. When I replaced the cap tube, I reclaimed the R22 for future use. After the TXV mod, I filled the unit with BBQ propane to gain experience and insight with the "impossible refrigerant". In reality, it works quite well.  The compressor found in this unit is ultra common. Besides dehumidifiers, it is also used in many 5000 BTU window air conditioners. These compressors are pretty stout, and will survive a decent amount of torture. The only thing bad about them (and their big brothers, the 44Rxxx line) is that they are not built to withstand low suction pressure. So if the heat exchangers get clogged up, either by frosting up or being clogged with lint or other air blockage, the compressor will eventually cook itself to death. This unit has a built-in thermistor for defrost sensing. The sensor is clipped onto the evaporator piping, and can be moved up or down for more or less sensitivity to frost formation. As you can see in my pic, I have my defrost sensor situated pretty low on the coil to increase cycle time. I found that these units can be set so that they run constantly. When the evaporator frosted over, the built-in defrost stopped the compressor and ran the evaporator fan like it should. That's how i ran my unit. I had it rigged to a waterbed thermostat so that the compressor ran when the thermostat called for heat. The additional blower was wired in parallel with the compressor, so it only ran when the compressor did. The control board handled defrosting quite well on its own.  The wiring diagram on the inside of the unit cover shows that the compressor runs off the red wire from the control board. Fan high speed is orange, low speed is blue.  I was lucky with this unit: the wires have labels molded into the control panel cover! I disconnected the red wire from the control panel, and wired it to the output side of my thermostat. I then wired the terminal where the red wire connected to the input or "line" side of the waterbed thermostat. This way, the control panel would still control defrost and I could turn everything off from the control panel. When it was acting as a heat pump, it did a better job of space heating than a space heater (that you could plug into a wall outlet) ever could. It worked great down to around 40 degF. For operation below 40degF outdoors, I rigged a little defrost "gimmick" up to the unit. A super small mag-drive pump was stuck into the bottom of a rubbermaid container, which the unit sat in. While it was doing its job, the unit weeped constantly and filled the tote. The pump outlet was run up the unit along the compressor discharge line, which heated the water somewhat. The water line was then run to the top of the evaporator, where the warmed water kept a portion of the evaporator warm. When the unit tripped its defrost, the somewhat warm water flow was enough to defrost most of the evaporator in a few minutes due to conduction in the pipes and fins. I got it to work down to about 30 degF using this method. Last edited by jeff5may; 11-22-14 at 08:26 PM.. |

|

|

|

|

|

#13 |

|

Supreme EcoRenovator

|

So without modifying the plumbing in a prefab unit, there are a few things you can do to defrost the units:

1. Bimetal switch defrost thermometer (klixon thermostat) 2. Digital sensor and control board (thermistor or digital thermometer sensing) With dehumidifiers, the defrost sensor is usually in a good place. All you must do is separate the airflow between heat exchangers to isolate the heat transfer you want to discard. With the newer portable spot coolers, indoor air is sucked in by the unit and the flows of hot air and cold air are exhausted seperately. To heat with a portable aircon unit, the cold air flow is exhausted out a window or vent to outdoors. For sub-freezing outdoor conditions, the dehumidifiers are best run in this configuration also.  This configuration has been criticized by many due to the fact that the living space is operated in a "negative pressure" condition. Since we are exhausting a portion of the airflow, that portion has to come from outside the living space. In reality, unless the unit is heating your whole living area, and this area is very airtight, the increase in heat output that the unit produces (due to sucking in warm room air, the unit operates at much higher suction pressure than if it were sucking in cold outdoor air) more than offsets the relatively small portion of infiltrating cold air. Plus, the unit hardly ever needs to be defrosted. Some of the newest portable units have split the airflows completely in the design process. These units are the easiest to modify to provide heating during the winter. However, the performance of these units suffers when it gets really cold outside. At some point, there is a temperature below which the unit will begin to frost up (needing defrost) in which case it would be more efficient to draw in at least some indoor air to raise the evaporator operating temperature.  There is a third method to defrost the evaporator: active heating. This mode works like a freezer, where the unit basically shuts down every so often to defrost the evaporator with a resistance heating element. This is the least efficient method of defrosting, but it does work. The sensing and control method must be planned well to avoid any unnecessary defrosts. |

|

|

|

|

|

#14 |

|

Supreme EcoRenovator

|

If you want or need to actively control the defrost cycle in your machine, there are a number of premade boards available for cheap. The two main manufacturers of these boards are ICM and Ranco. The control boards of both manufacturers cross-reference directly to each other, and to a zillion rebranded proprietary part numbers.

My two favorite defrost boards are the ICM 300 and the ICM 315. They can both be found on ebay for around 20 dollars just about always. Depending on how you are going to assume control of your unit, one or the other will do a better job than the other. When installed correctly, they both serve as industry-standard devices as to reliability and performance. The ICM 300 is a truck-stock item in service trucks, due to its popularity and flexibility. It has been integrated into millions of heat pump units over the years. It is made to be wired in series with a bimetal klixon thermostat, receiving power only when the thermostat is active. It wires to a separate "defrost relay" which in most cases looks like an ice cube.  The virtue of a separate defrost relay is that you may rig the relay contacts so they force whatever mode of operation you want to command during the defrost mode. This type of control can be recycled through several revisions or machines, and will operate like you wire it pretty much flawlessly forever. The ICM 315 has its own, onboard power supply and control relay. It can be rigged to either a bimetal switch thermostat or a thermistor, depending on how you want to do your defrost. This one works well with the passive defrost units described previously. If you figure out some wiring details, this one can be rigged without any extra devices to enforce defrost control. Last edited by jeff5may; 11-16-15 at 06:21 PM.. |

|

|

|

|

| Tags |

| defrost, evaporator, frost |

|

|