|

|

|

#31 |

|

Helper EcoRenovator

Join Date: May 2016

Location: SE Wisconsin

Posts: 55

Thanks: 3

Thanked 14 Times in 10 Posts

|

Before I started this project I read that ground source heat pump thread. It would be good for me to read it again, I am better able to comprehend it now. Next week I will start collecting and reporting data.

It sure seems like the fan is pulling too much air for the large evaporator that I have. At some point I could rig up a weaker fan. The current fan takes about 85 of the 350 watts. My original plan was to use a passive evaporator to save those watts, I might get back to that sometime in the future. |

|

|

|

|

|

#32 |

|

Supreme EcoRenovator

|

I put a light dimmer on the fans I want to slow down. For the window units that become heat pumps, the low speed is still too fast for defrost mode. The fan motor can be varied to whatever speed you need. Super cheap, too.

|

|

|

|

| The Following User Says Thank You to jeff5may For This Useful Post: | IdleMind (06-10-16) |

|

|

#33 |

|

Journeyman EcoRenovator

Join Date: Apr 2015

Location: Oxford, MS USA

Posts: 496

Thanks: 69

Thanked 87 Times in 61 Posts

|

Awesome thread. Being able to find txv for less than $10 is the way to go. You can learn A LOT by using cap tubes and even a needle valve in front of the cap tubes, but in the end a cheap txv saves time and money. In fact the coming week I will be posting the updates to the HPWH that include a txv.

Light dimmers are awesome for slowing the fan down. But a have had lots of luck with DC fans as well. More control and they use less watts per cfm. It is hard to tell just how efficient your water tank heat exchanger is working. It looks freaking amazing, and by your numbers we know it is working pretty good for sure, I like how the copper doesn't have to be IN the water. This helps with corrosion. Awesome work cant wait to see more updates.

__________________

שְׁמַע יִשְׂרָאֵל ה' אֱלֹהֵינוּ ה' אֶחָד |

|

|

|

|

|

#34 | |

|

Supreme EcoRenovator

|

Quote:

Last edited by jeff5may; 06-12-16 at 01:27 PM.. |

|

|

|

|

|

|

#35 |

|

Journeyman EcoRenovator

Join Date: Apr 2015

Location: Oxford, MS USA

Posts: 496

Thanks: 69

Thanked 87 Times in 61 Posts

|

Jeff, I more meant that if the cap has to be adjusted time and time and time and time again, that I txv saves time and money on refrigerate. I probably opened my system 6 or more times before getting it right. A cheap txv would have saved me SO much. BUT you are right once the right size cap tube has been made it is best to stay with it. Unless you alter the system SO much that more time again would be wasted on getting the right size yet again.

Plus I'm going to charge with R1270, and that stuff cost WAY to much to waste. =D

__________________

שְׁמַע יִשְׂרָאֵל ה' אֱלֹהֵינוּ ה' אֶחָד |

|

|

|

|

|

#36 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

Memphis,

Your future synopsis will be very instructive and I am eager to read it. For example, you completely buy in on a tvx. I too wish to make use of all your time effort and endless refills of your system. A few parts may costs just a bit more, but we look forward to you bottom line wisdom. Thanks in advance. Steve

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 |

|

|

|

|

|

#37 | |

|

Supreme EcoRenovator

|

Quote:

|

|

|

|

|

|

|

#38 |

|

Helper EcoRenovator

Join Date: Jul 2012

Location: Jacksonville, fl

Posts: 48

Thanks: 3

Thanked 14 Times in 10 Posts

|

Dont forget that the cycle is dependent on ALL variables. While your evap will probably remain fairly stable, you will still have seasonal differences with temperature and humidity. You are also dealing with a fairly significant temperature swing on your condenser from 60 to 120F. Captube flows are directly related to delta pressures. A txv takes care of highside pressure swings as a byproduct of maintaining superheat on the suction. A small receiver could help with the temperature swings and keep the highside more stable and always maintain liquid at the txv (since a cold tank will have significantly more liquid ref in it than a hot tank, it needs somewhere to go).

It also doesnt matter how much of your evap is flooded as long as the superheat is maintained. The txv mostly eliminates the purpose of the accumulator function on the compressor, which is why the receiver is suggested. Most txv come out of the box preset 10~20*F superheat and should work without adjusting at all. It dynamically changes flowrates as the conditions demand, vs fixed metering which is tunable only for a specific design condition. With a TXV you charge for subcooling instead. Charging with a receiver is a little bit of a different procedure, but it is more tolerant of high side pressure swings. |

|

|

|

|

|

#39 |

|

Helper EcoRenovator

Join Date: May 2016

Location: SE Wisconsin

Posts: 55

Thanks: 3

Thanked 14 Times in 10 Posts

|

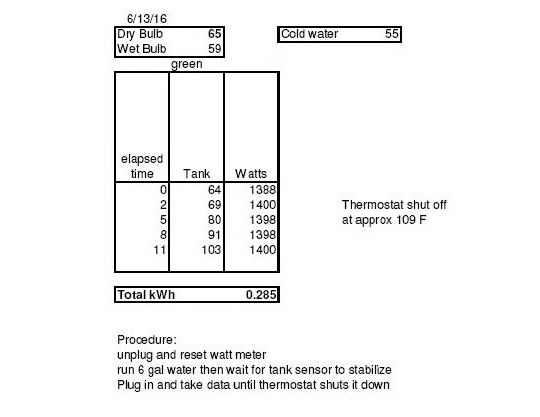

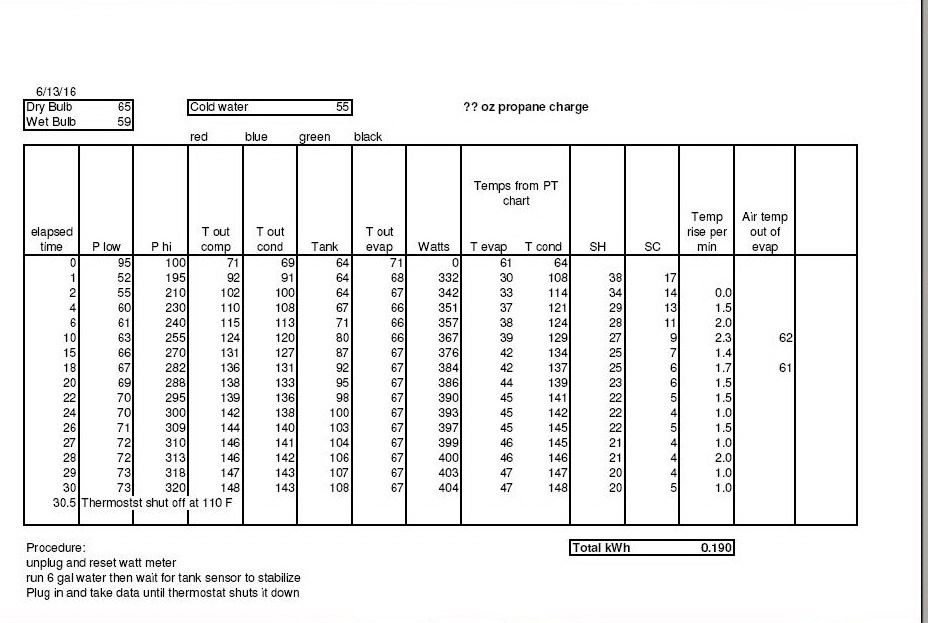

I got 2 more thermocouples, the one on the tank is shown in photo. The cover over the thermostat was removed and the thermocouple is held tight against the tank by the shinny magnet in upper left. Then the cover was replaced.

The procedure is to unplug power and run 6 gal of water through the tank to cool it down. Then start it up and collect data. The first test is using the stock resistance heater.  The second test is using heat pump. I believe there is very small leak so I don't know the exact charge, but probably around 2 to 2.5 oz.  |

|

|

|

|

|

#40 |

|

Helper EcoRenovator

Join Date: Jul 2012

Location: Jacksonville, fl

Posts: 48

Thanks: 3

Thanked 14 Times in 10 Posts

|

That paints a much clearer picture of what's going on. It's without doubt undercharged, the calculated SC at the 30min mark is 17*F where you have 4-5*. I would bring up the SC and re-evaluate the SH and decide on fan speed and captube length. A lower SH will dehumidify better, but could cost you efficiency and may fall outside the compressors operating ability. Shooting for 10-15 is a good safe realm.

Some other calculations, you applied 916btu of heat from start to stop, which averages 30.55btu/minute or a total capacity of 1840btu/hr. With an average wattage of 378w, meaning your getting an averaged return of 1.4 times applied heat over just electricity consumed. The target evap exit temp is about 15* off, with a target at these conditions of a Delta of 18*F. This is a result of too much airflow and insufficient refrigerant flow. The evaporator absorbed 550btu/hr from the environment, some of which was applied to condensation of moisture. The other 1290btu was aquired from the compressor. (Note, the evaporator btu calc is skewed by the inclusion of the fan motor which does not apply appreciable heat to the system!) There are 3.412142 BTU/hr in 1 watt And 8.33 btu to raise 1 gallon 1 degree F. Last edited by RB855; 06-13-16 at 09:16 PM.. |

|

|

|

| The Following User Says Thank You to RB855 For This Useful Post: | jeff5may (10-11-16) |

|

| Thread Tools | |

| Display Modes | |

|

|