|

|

|

#1 |

|

Lurking Renovator

Join Date: Dec 2016

Location: Texas

Posts: 14

Thanks: 3

Thanked 3 Times in 2 Posts

|

I found this site using a search and found you guys the most knowledgeable.

I had 2 units installed 3 years ago by a local firm (that unfortunately had to close it's doors). I reached out to a another local A/C company that is listed on Mitsubishi's website as a Diamond contractor. This started back in October of this year. One unit is secured to concrete (no problems at all) and the other is suspended from a wall using manufacturer brackets. Tech1: He was a nice guy, didn't really know the unit all that well and was trying to service it at the head unit. He then called another tech who told him to simply add refrigerant and call it a day. I watched this tech the entire time. Using his gauges, he then proceeded to put refrigerant in the unit. At one point he purged some of the refrigerant as he had put too much in. He left and wasn't confident that this resolved the issue. The unit ran for 3 days making all kinds of noises and never cooled so I turned it off and contacted the company again. Tech2: Again, really nice guy. He began to use a spray to test the connections on the outdoor unit and found one connection loose. He tightened the connection, used a scale and gauges to put bring the refrigerant to a proper level. He then had me set the temps low (outdoor temp was 95) and verified the unit was cooling properly. He left and I had to pay for his visit. I quickly had the office remove the first charge. Tech3: This tech was the one most familiar and was the one responsible for training the other techs (yes, I know). He checks all the connections and found the connections at the head unit loose as well. He tightened all the connections and performed the same process as tech #2. He then indicated that he would return 1 week later to check the levels and to call if I noticed any problems. I called and delayed his return as things were working fine. Then in mid December we had temps drop into the teens. This is when I noticed the heat stopped working. So I called back and Tech#3 returned with another tech (in training). Diagnosis: Tech 3 verified all the connections on the outside of the unit were to spec. I didn't watch what they were doing this time but they asked to come into the house so they could check the head unit. They used a tool and identified the leak coming from the evap coil (think that's what they called it). They showed me and I could see oil on the aluminum fins. They took photos of the unit (leak) and the serial number and indicated that the office would call me about a replacement coil (?) or possibly a replacement head (if they could find one; Mitsubishi GE09-NA). They also asked who initially installed the unit (I gave them the name of the firm). (many apologies for the long story) So is it possible that: [1] Tech #1 over pressurized the system initially causing the failure. [2] The unit just failed after 3 years of service. [3] A combination of #1 and 2. Thoughts? Much appreciated... -- Shelby |

|

|

|

|

|

#2 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

I'm somewhat familiar with Sanyo MS and they have over-pressure sensors,

that are suppose to kick in, and shut down the system if the pressure goes too high.. However, I once had a brand new system that popped a hole in the copper tube coming from the compressor, resulting in the loss of all the R410a. I assume it had the required amount of R410a refrigerant from the factory. But, I could be wrong.. If someone added more refrigerant than was required by the system, that could cause serious over-pressure, resulting in a leakage problem. Because most MS systems only have a single service port, it's not easy to accurately add R410a to these type of systems. The standard procedure that many techs use, is to recover all the R410a, weigh it to see if the right amount was in the system.. Then, charge the system with the correct amount of R410a. The outdoor unit tag has the amount if R410a listed in pounds.. The length of line-set is a factor. If the line-set is longer than about 25 feet, then more R410a is added per-foot, per the install manual. If the line set is under 15 feet, the manual might recommend recovering a small amount of R410a. To avoid over-pressure. It's a well known fact that some HVAC techs do not have much experience working on mini-splits.. While some are experts, many are not.. I have a very basic EPA certificate. (So I can work on my own stuff). But, I'm not an expert by a long shot..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#3 |

|

Helper EcoRenovator

Join Date: Sep 2014

Location: Columbus, OH

Posts: 34

Thanks: 1

Thanked 5 Times in 5 Posts

|

I wouldn't be surprised if it was just simply bad luck either. I remember reading somewhere about r410a systems having issues with popping holes in the coils due to a combination of the increased pressure and the tubing being rifled causing weak spots. Anecdotally, I know my dads split system sprung a leak within a couple of years of moving into his house (r410a). In the meantime, my R22 system is going on 20 years old now with no issues other than a start capacitor two summers ago. No clue if MS coils are the same, but I'd assume so as rifling the tubing increases the internal surface area of the tubing, allowing them to squeeze a little more out of a unit at any given size.

|

|

|

|

|

|

#4 |

|

Lurking Renovator

Join Date: Dec 2016

Location: Texas

Posts: 14

Thanks: 3

Thanked 3 Times in 2 Posts

|

Thanks guys and Happy New Year !

I just reviewed my warranty paperwork and I'm (fingers crossed) hoping that the head unit will be replaced (5 years on parts). Sounds like I'll have to pay for labor to remove and replace. I could easily accept a defect the 1st year of use - e.g. a summer and winter but 3 years is kind of strange. I didn't mention the issue of the 1st tech to the field supervisor as I'm simply unsure if this truly was the cause aside from being a complete coincidence. I'll keep this thread updated. I had hoped they would have contacted me today but given that this is so close to a holiday weekend - I can certainly understand. Again thanks SO much for replies .... --Shelby |

|

|

|

|

|

#5 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

R22 pressures run a good bit lower than R410a.

A 100 deg F, R22 = <200 PSI whereas R410a = >300 PSI. One of the main problems with the change over to R410a has been it's pressure. ~~~~ Okay Shelby.. I hope the techs turned off both service valves when they found the indoor leak. Otherwise all the R410a in the system will have vented into your home.  When they change out the indoor unit, perhaps they will check the flares on both ends of the line-set and insure they are torqued to spec. (I use Refrigeration Technologies RT201B NYLOG sealant on flares). They will most likely Recover any remaining R410a, pressure test and then vacuum the system.. Before they re-charge the system with new R410a, using a scale, to weigh it in.. You should be able to find some MS install videos on YouTube, so you will have a better idea of what the installers are doing at each step..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#6 |

|

Lurking Renovator

Join Date: Dec 2016

Location: Texas

Posts: 14

Thanks: 3

Thanked 3 Times in 2 Posts

|

Yes, the supervisor indicated that the head pressure is much higher when using the heat pump on these systems. I assume he attributed the failure to that.

I can clearly see the oily residue on the indoor unit fins - looks like the coil is made of aluminum. Perhaps manufacturers differ in the strength of the aluminum (cost?) and I wouldn't know if it's a contiguous piece or sectioned/ joined using some method. I simply cannot see where it's leaking from, |

|

|

|

|

|

#7 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Aluminum works pretty well. I have a line-set that has copper bonded to the Aluminum tubes, on both ends.

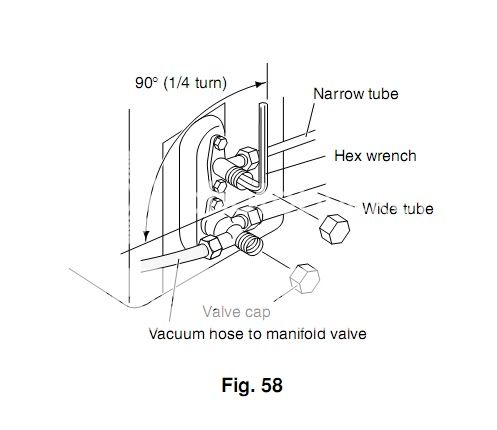

Copper can be flared and used with MS type connectors. Is it still leaking out? If it is, you might want to close both of the service valves, and pull out the power disconnect. (So it can Not get power, while the line-set is cut off from the outdoor unit). Clockwise with the hex key is off.. They will need a few turns to the stop..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

| The Following User Says Thank You to Xringer For This Useful Post: | Shelby (12-30-16) |

|

|

#8 | |

|

Lurking Renovator

Join Date: Dec 2016

Location: Texas

Posts: 14

Thanks: 3

Thanked 3 Times in 2 Posts

|

I suspect anything in the unit leaked out at least a week or so ago. I didn't see what they put in the system this morning to test but I did see them use a leak detector. They actually left the unit powered on and running when they left (8:30 am) - I had to actually turn off the unit using the remote. They seemed to believe they'd be back today but I've heard nothing.

I'll go out in the morning and close the 'valves' and kill power all together to the unit. Many, many thanks Xringer .... Quote:

|

|

|

|

|

|

|

#9 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Yeah, that might even help keep moisture out of the system.

With a hole in the indoor unit, and sun hitting the outdoor unit, the system will breathe out, and back in at night. Moisture is the enemy of R410a, and a vacuum pump will have to remove all of it from the system. More moisture (damp air) inside the system means it will take longer to dry it out. As the vacuum gets deep, water will boil, turn into vapor and be sucked out by the pump. I once repaired a leaky outdoor unit that had been exposed to air (a small hole) for many months. Seemingly, the POE oil (Polyolester oil) in the system was still good. Once the hole was brazed over, and pressure testing and vacuuming was done, we just charged the unit up and used it. It lasted a few years, before a grid power glitch killed the main control board..  Here's the link, if you get bored over the weekend..  http://ecorenovator.org/forum/geothe...r-project.html Where are you at in Texas? I was born DITHOT but left (Navy) when I was 17.. this month, I'll be 71. Things are reversing around..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#10 |

|

Master EcoRenovator

Join Date: Jun 2013

Location: USA

Posts: 543

Thanks: 6

Thanked 44 Times in 38 Posts

|

Do not know how the warranty reads , but in my mind , any leak internal to the outdoor or the indoor units is a manufacturing defect .

Now , comes the interesting part . God bless Wyr |

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|