|

|

Advanced Search | |||||||

|

|

|

Thread Tools | Display Modes |

|

|

#31 |

|

Helper EcoRenovator

Join Date: Nov 2016

Location: Romania

Posts: 47

Thanks: 19

Thanked 0 Times in 0 Posts

|

Great idea, I will try to research more on that, thanks a lot.

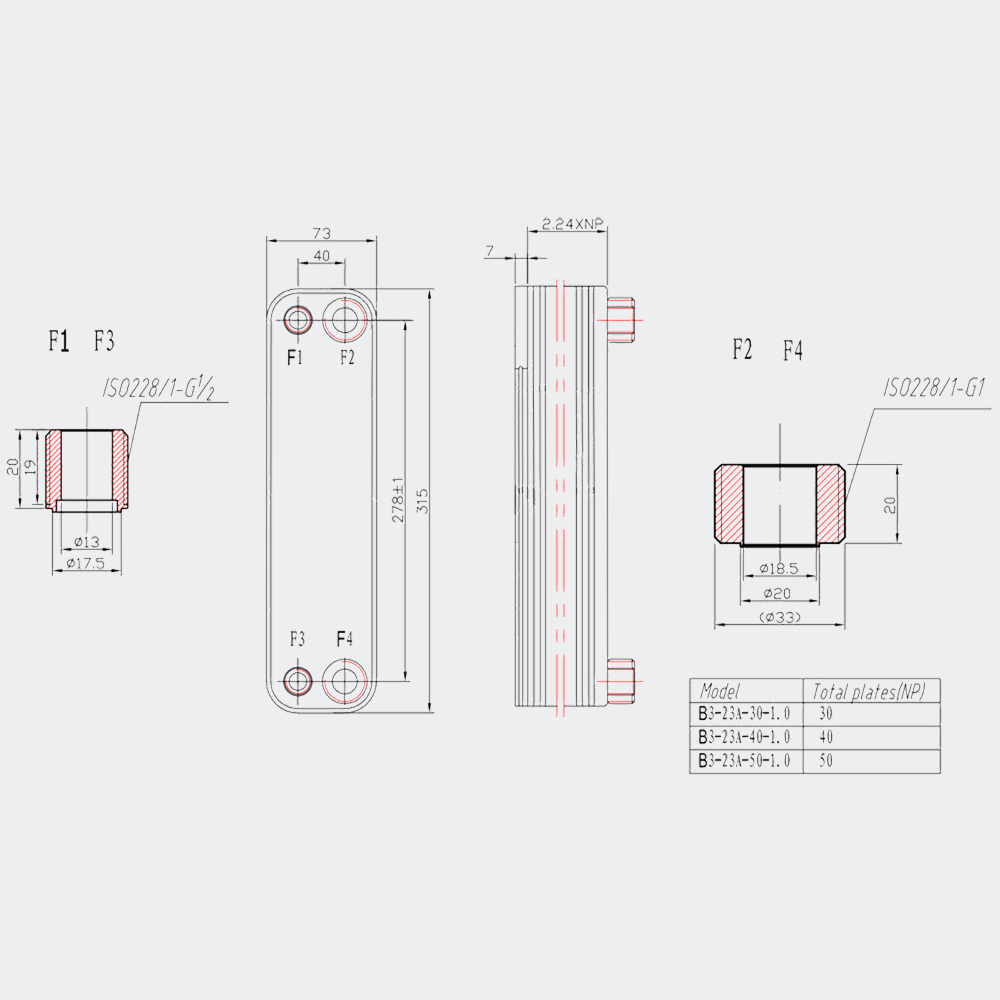

In the mean time I ve got a good offer for a heat exchanger that looks undersized for its specs , would this fit my unit ? I mean the price its very affordable, so please tell me if this would work because I ve very enthusiast about having it sorted that cheaply. http://shop.wiltec.info/product_info...er-125-kW.html  Model B3-23A-30 Number of plates 30 Length / Width / Height (without connections, in mm) 315 / 73 / 74,2 max. flow 4 m³ / h Connecting height 20 mm Capacity 0,040 l per Plate = 1,20 Liter Effective exchange surface 0,023 m² per Plate = ca. 0,69 m² Temperature range -195°C up to +225 °C Operating pressure 20 bar Power max. 125 kW Plate material stainless steel AISI 304 Connecting piece material stainless steel AISI 304 Circulation F1 -> F3 / F4 -> F2 Connectors F1 & F3 12,7mm (1/2") (according to ISO-G) F2 & F4 25,4mm (1") (according to ISO-G) Soldering material 99,9% copper Weight in kg 2,5   Last edited by b420ady; 11-22-16 at 11:27 PM.. |

|

|

|

|

|

#32 |

|

Helper EcoRenovator

Join Date: Nov 2016

Location: Romania

Posts: 47

Thanks: 19

Thanked 0 Times in 0 Posts

|

Can someone here help me find out which one of these heat exchangers would work for my unit ???

http://shop.wiltec.info/index.php/ca...Exchanger.html AC_Hacker I ve read your post on heat pump manifesto about calculating the heat exchanger size , how big a heat exchanger sould be for my 14-15 Celsius water source to work efficiently with my 2,5 KW input power heat pump... I expect the COP will be around 5 so I ll have to extract 12,5 KW/h of heat from that cold water. Last edited by b420ady; 11-22-16 at 11:42 PM.. |

|

|

|

|

|

#33 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

The problem with these "flat plate" collectors is that they eventually clog up (block up) with debris when you use a well as a water source. Jeff also referred to this earlier.

It will work for a while, but it will clog up. Secondly, I am not sure of the ability to transfer all the energy you need through one flat plate unit. If you had clean, pure water - or were using a closed loop - then several in parallel might work. My guestimate is that one will work for about 6-8 kBTU/hr If you are willing to back flush these units (to remove debris) and are willing to install several, then you might be OK for a while. By far, the better solution would be to use a coaxial copper in copper heat exchanger where water debris has a much higher chance of being flushed through. On my well, I have the coaxial type heat exchangers and have had no problems for almost 25 years. But they are hard to get for you. I am thinking that a long coil of copper tubing, immersed in water, might be a more effective heat exchanger. It will be a lot of copper (100 meters?) in a small tank 100 liters, but that would NOT clog up. I understand that you can get copper tubing inexpensively. Steve

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 |

|

|

|

|

|

#34 |

|

Supreme EcoRenovator

|

Not big enough. That one is barely large enough to work as an evaporator on a 5000 btu window unit. It would work as a desuperheater for domestic hot water, though. It could possibly handle 22KW if it were condensing steam or something similar, but with a 10 DegC water-side temp drop (max), you would need a 40 plate one of these. With that many plates, you start running into liquid distribution problems, where some plates will try to freeze before others due to low flow. No problem for heating, bad news for cooling. If you try to get away cheap, Murphy's Law is always waiting in the shadows to help you spend more money...

Here's a good brochure that describes working conditions and size/capacity/dimensions briefly. A quick and dirty measure for brazed plate evaporators is unit weight. At 10 DegC water temp drop and 10 EER and 1 ton of capacity, the thing should weigh at least 1 Kilogram. More plates = more mass = better EER. So for a 2 ton unit, it should weigh at least 2 kilos. The one you linked to weighs 0.6 kilo, so if it's a good performer, the best you can hope for out of it is around 8000 btu per hour. Conservative rating would be closer to 5-6kbtu. This agrees with what Alfa Laval recommends in this document. If you want just enough heat exchanger (7.2 KW~2 ton), they recommend model# ACH-30EQ-20H (20 plate, 50% longer plates than the linked product). It weighs in at 3 kilos. For extra flexibility, they recommend the same size in a 30 plate thick model (ACH-30EQ-30H). Rated at 11 KW~3.5 ton, it weighs in at 4 kilos. Alfa Laval: Evaporating http://www.freecalc.com/hxfram.htm Last edited by jeff5may; 11-23-16 at 09:07 AM.. Reason: spelling and such |

|

|

|

|

|

#35 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

Jeff, - thanks for confirming my "guestimate" of 6-8 Kbtu/hour for each of the heat exchangers described above.

Very good way of sizing through weight. Thanks for that. Steve

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 |

|

|

|

|

|

#36 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

b420ady

Your question to the brazed plate HX's I used were rated at 72,000 BTUs maybe a little larger than you require. And they cost me $394.00 USD back in 2013 I ordered them from China. Product from the US were 35% more The ones you are looking at are a little small but your thinking the price is right. The coaxial HX that you should use for your build ranges between $350.00 to $550.00 USD depending on the supplier. You may be able to source them cheaper else-where. Please understand I'm only too willing to help but we both need to be reasonable. I fully realize it would be totally wrong to buy all the pieces to hack the HP you now have now if it cost more to hack, than buy one. You will also need tools. Torch, Gage set, vacuum pump (you can build this) Brazing rods etc. We don't know the condition of the compressor in your HP. Will it run or is that why it was on the scrap pile???? The other part of the equation is the water source. Pumping 1000's of ltrs. of water from your well may exhaust it. Especially if your not sending it back to the aquifer. The energy (electricity) used to lift the water 40m is going to cost. $$$$$ You seem like a smart fellow and some of the other ecorenovators provided a required quantity of ltrs. to supply this. You can calculate roughly how much it will cost per hour to supply that water. And heres a little information, the fan in a air to air heat-pump will use less energy to move air than a water pump from 40m. What is the cost of a 2 ton air to air heat-pump there??? I checked the US prices and an inexpensive one is $1000.00USD You maybe able to source a Chinese H/P Again I'm only willing to help but it has to make financial sense.!! Hacked unit + $350.00 Coaxial+ $200.00 tools + cost of piping to well + odds and ends= more than new unit????? possibly My story is a little different a heat-pump for my shop was $7000.00 to purchase. $800.00 for heat exchangers + $350 for surplus 6 ton compressor (new)+ $300 for Variable freq. drive. I already have all the tools. + $300 pumps & odds & ends = $1700.00 approx. If I add the cost of my ground loop HDPE tubing $600 (close out sale) $1000.00 for the excavation Saved a ton of money. ($3500.00) Plus heating with furnace oil cost me $3000.00 per year. So my Return of Investment was less than 2 yrs. (but thats my case) The vapour compression machines are great technology and their cost to operate is quite low. I would highly recommend these to anyone. To spend a lot of money on a questionable outcome??? If you want to make this a hobby, I get it. But what information you have given me leads me to this. Again I (we here) are here to help you BUT lets not send you down the wrong road. Randen |

|

|

|

| The Following 3 Users Say Thank You to randen For This Useful Post: |

|

|

#37 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

These are the heat exchangers. The brazed plate is quite large upwards of 6 tons made in China. These HX's caused me a little grief as the threads are not standard here. Lucky enough I have a lathe. You may run into problems like this when you build your own.

As we say" It's no free lunch" The spiraled coaxial is what you need using well water but as mentioned its not going to be easy. On a really cold night when you need a lot of heat and your trying to draw that heat out of cold well water, how are you going to prevent the water from freezing solid in your HX. That could freeze and split your HX. You will need freeze protection circuit. The newer Mini Split heat-pumps are getting better and provide heat down to lower temps. Ask X-ringer You can install it yourself!! Randen |

|

|

|

|

|

#38 |

|

Helper EcoRenovator

Join Date: Nov 2016

Location: Romania

Posts: 47

Thanks: 19

Thanked 0 Times in 0 Posts

|

Thanks randen for enlighten me, you are so right about plate heat exchangers as I ve also read on some romanian documentation which I ve found on google and it was amazing well done and made me understand a lot about the realities of these systems ... Anyway as you also spoke about the costs of the homemade version vs commercial units I realized that I never looked again for local prices for geothermal heat pumps as I already knew since a lot of years ago that they are huge in Romania. There is no second hand market for heat pumps here ... apparently no one needs to sell suck a think as its a pretty new technology here. Anyway, apparently the cheapest water to water unit here that is 13.6 KW in power output is about ......wait for it.....

9184 USD (39.268 RON in Romanian currency) here is the unit: POMPE DE CALDURA APA-APA VIESSMANN VITOCAL 300-G tip WW 13.6 kW - CALOR scroll down a bit the page and you see a photo whith the inside of it and they are plate heat exchangers .... I though W*F how can they sell that at that price ???? I also don t understand how that unit is weight 152 KG (335 pounds) .... can someone explain me that .... i don t understand... the case of the unit is made out of lead or those heat exchangers are something else maybe gold bars ???  If those heat exchangers are the same thing with what you used and the Wiltech one I ve shown you and they are 3-4 kg heavy the whole unit should be maybe 15.2 Kg not 152 Kg heavy and thats 10 times less than how much they say it weight. Than I have found another unit on the local market in the same huge price range: https://www.ferroli.ro/media/pdf/Man...nic_HXW_EN.pdf There is a lot of data inside there , take a deep look They say that they are using "stainless steel brazed plates" with water volume 2,56 Liters , so I ve search at Wiltech for a similar unit with 2,5 Liters of water inside and I ve found this 7.5 KG heavy steel brick which is 270 USD : WilTec - Plattenwärmeübertrager | PWT | Solar | BHKW | Edelstahl Wärmetauscher 50 Platten Plattenwärmetauscher max. 285 kW 50683  I guess the "stainless steel brazed plates heat echangers" are much better than cooper ones for the well water because cooper is reacting with water. Using stainless steel plate heat exchangers I guess I will still have to unscrew the water lines from it from time to time (a reasonable amount I HOPE ... like 1-2 times in a winter at most ) and do some kind of chemical flush or ultrasounds or combined or something else I really need more info on this, please help |

|

|

|

|

|

#39 | |

|

Helper EcoRenovator

Join Date: Nov 2016

Location: Romania

Posts: 47

Thanks: 19

Thanked 0 Times in 0 Posts

|

Quote:

The air heat pumps cannot work here in winter at -25 degrees Celsius , until now my best bet is to build somehow the best coaxial heat exchanger I can do, I will research more how can I transform regular cooper pipe with a pipe threader to something more similar to what they put in those coaxial heat exchangers OR use more thinner pipes , the thinnest one I could easily find was about 6 mm at a decent price and 4 mm which was 6.7 USD PER METER ! ! ! https://www.mag-pro.ro/romanian/102110.html , I ve seen some photos with commercial coaxial heat exchangers with 4 or more cooper pipes inside the shell pipe, do you have any ideea how small they are in diameter so I can search for them online ?  Coaxial Heat Exchanger | Heat Exchangers, Weldolets, Fittings, Flanges | Anthermo GmbH Or if you have any idea how can I bent a cooper pipe like a spiral let please let me know because the only thing I can find is to make a spiral out of the pipe not change the circle profile of the pipe to a spiraling star shape profile I imagine something like Jeff showed us with rollers at a smaller level plus a torch to preheat the pipe for easier operation. Anyway that threader head cannot be done without a CNC and a lot of engineering...also to buy one it will be even more expensive http://www.doucetteindustries.com/Po...5tons_Evap.pdf |

|

|

|

|

|

|

#40 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

From a Mitsubishi Mini-split site

-13 F. Deg = -25 C. Deg. and a 3 ton is $2100.00USD Inverter-driven compressors. This allows the compressor to ramp up and ramp down as the cooling or heating need increases or decreases. The benefit: fantastic energy efficiency. Can operate with full heating performance down to 15 F! Also the heat pump can start with instant heat down to -13 F! Conventional heat pumps are typically useless when the temperature is less than 30 - 35 F. The most efficiency Mitsubishi heat pump can operate as high as 26 SEER and 10.5 HSPF, one of the most efficient heat pumps in the industry. Mitsubishi's iSee sensor uses infrared technology to do a 150 degree scan of the room to detect hot/cold spots in the room. Once a hot/cold spot is detected, the airflow direction is adjusted to resolve this climate control problem. B420ady I see just a whole lot of pain trying to build everything with limited resources. I really question using well water from 40m. as being economical. How often does the temp drop to -25 Deg C.?? I had little success with DIY tube in tube HX. A few freeze-ups splitting my HX's and you may get this with cold fresh well water, shutting down your heat. But if you have some ideas we can all learn from your endeavours. You will spend lots of dollars and hours replicating what research and development that some of the manufactures have spent 1000 fold. Randen |

|

|

|

|

|

|