|

|

|

#51 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

Memphis - this "oil return" line is getting complicated and fraught with potential problems. The number of connections (each with potential leaks) also increases the gas loss issue. I am very good at copper pipe soldering and am surprised when I have a pin hole leak - but it happens.

I am thinking a water exchange poly pipe coil in the pond, with a heat exchanger, will be a simpler, lower cost, time tested and more reliable solution. There is beauty in simplicity. DX may appear to be that on the surface, but multiple coils, oil return lines, etc look problematic to me. But I do NOT want to be any wet towel here! You have done impressive work and it is ALWAYS better to think out a system before building it physically. Steve

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 |

|

|

|

|

|

#52 |

|

Journeyman EcoRenovator

Join Date: Apr 2015

Location: Oxford, MS USA

Posts: 496

Thanks: 69

Thanked 87 Times in 61 Posts

|

Wise advice. Yes the water based closed loop systems do seem to be the easiest install and less maintenance. On top of cheaper and might just be more efficient. There are flat plate exchangers and tons of info on how to make them run well. I will be giving that option some thought.

DX is just so rare. And the techs that put them in are not as willing to talk specs as most HVAC guys are. I would love to blue the doors wide open for more DIY guys to be able to use this type set up. I have unlimited options. They may not. Oil oil oil is the problem. Sure a set of lines can be way to big for the compressor to handle but oil return looks to be the number one issue with DX. AC says a document exist that has hard facts and numbers on the oil return. If I can find that and design a system that will nitre than likely work then I will continue with DX. If not, closed loop of pump and dump seems wisest. Thanks for your input. |

|

|

|

|

|

#53 |

|

Supreme EcoRenovator

|

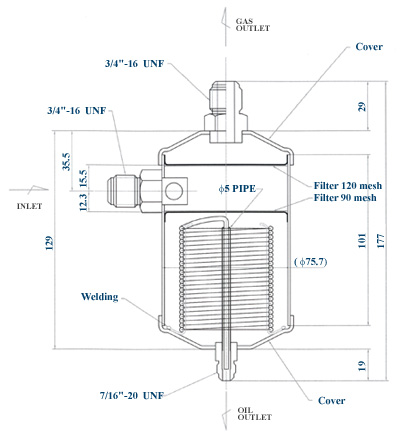

This magic device is called an oil separator.

Inside the shell:  Last edited by jeff5may; 07-25-15 at 04:02 PM.. |

|

|

|

|

|

#54 | ||

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

I was looking over your sketch, and I am curious why you want the compressor near the house? If your project idea is to use condensing DX inside the house, then I get it. But if your idea is to go through an HX at the compressor, and use heated water as your heat transfer medium, or something, you might consider a different approach. If you re-located your compressor to be nearer your pond, you would be able to shorten the overall length of your copper. You would also keep the possibility of any R290 leaks, removed a safe distance from your house, AND the problems would be down hill, which is very important. Don't know if you read my account in the 'Manifesto': Quote:

If there were problems, they would probably begin to show up there. If there were problems associated with size, length or diameter, etc., you could tweak and remedy the issue. Then with that confidence, you could replicate your configuration, and test out your manifold concept, and grow piece by piece. This way, your test loop would become one of several 'know good' loops if your final project. If you do this, and relocate your compressor near your pond, be sure to never lose sight of a healthy fear of electricity and water. I would suggest very strongly to have a GFI at the source of your power cord. Ask me how I know... -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 07-24-15 at 12:34 PM.. |

||

|

|

|

| The Following User Says Thank You to AC_Hacker For This Useful Post: | stevehull (07-24-15) |

|

|

#55 |

|

Supreme EcoRenovator

|

The magic device you seek is known as an oil separator. It resembles a muffler with a cap tube at the low point. Some are filled with copper or steel wool, or other , ,more exquisite material. The thing is plumbed in between the compressor discharge and the reversing valve. The cap tube taps into the suction line. No more oil return problem.

|

|

|

|

| The Following User Says Thank You to jeff5may For This Useful Post: | stevehull (07-24-15) |

|

|

#56 |

|

Journeyman EcoRenovator

Join Date: Apr 2015

Location: Oxford, MS USA

Posts: 496

Thanks: 69

Thanked 87 Times in 61 Posts

|

AC, the main reason the compressor is at the house is because that is where the air source unit is now. It makes it SO much easier and I saw no problems if I were doing it DX.

A small prototype is a good idea, I have a few compressors that might work well for it. Propane is scary stuff, I am a state certified firefighter, I've seen it do crazy things. Not as eerie as your story though, but I do vaguely remember reading as I power read through the entire thread. Jeff, YOU ARE AWESOME! I knew something like this had I exist. Q E HVAC R Refrigeration Oil Separator 7 8" ODS New | eBay I will continue reading up on it but it seems as though I can push the size of the pond loop now. I'm thinking 100 feet of 5/8 going out to the manifold, with 5 150 feet long 5/16 loops coming back through 100 feet of 1/2 to the compressor. Other than friction loss is there a problem with the loops being to big now that the oil is not an issue? That is less than $900 worth of copper. Btw I will super test the entire line set/manifold/loops on the ground for leaks before and after installation. Last edited by MEMPHIS91; 07-24-15 at 10:09 PM.. Reason: http://www.achrnews.com/articles/91004-selecting-installing-oil-separators |

|

|

|

|

|

#57 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

Whew - $900 for copper to make the DX work? Ouch!

Steve

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 |

|

|

|

|

|

#58 |

|

Journeyman EcoRenovator

Join Date: Apr 2015

Location: Oxford, MS USA

Posts: 496

Thanks: 69

Thanked 87 Times in 61 Posts

|

That's for a oversized system. More like 5 tons. The closed loop hdpe pipe would be about $800-$1,000 for the same size unit. Not including needed an extra pump and controls and anti freeze. I think the copper is the cheaper route.

|

|

|

|

|

|

#59 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

Memphis

I'm siding with AC_Hacker Obtain a small window shaker put it in the window of your home and take the condenser out and put a nice 3/8 or 5/15 copper loop down to your pond and back. Test the theory If after a few weeks you break open the loop and find a huge quantity of oil, there maybe trouble. On the other hand if there is very little you have the green light. I'm thinking the propane refrigerant being a petroleum distillant may keep the oil in a suspension returning it to the compressor. $900 for a 4 ton loop INEXPENSIVE!! like you have found no circ. pumps, no heat exchangers, no propylene glycol $$, heat pump nirvana!! Pure efficiency!! Randen |

|

|

|

|

|

#60 |

|

Journeyman EcoRenovator

Join Date: Apr 2015

Location: Oxford, MS USA

Posts: 496

Thanks: 69

Thanked 87 Times in 61 Posts

|

Randen, thanks. In fact I already have a perfect window unit just waiting for this project. Though after Jeff told me about the oil separator , I am convinced oil will not be the problem. It will give me more Peace of mind if no oil is in the coil without a separator. I really need to know sizing of the pond loops. And this test should help with that.

I am thinking now that 2 oil separators back to back will make sure I get no oil in the pond loops. Been reading articles that are saying the oil is bad in a DX system anyway because it coats the inside of the tubing and blocks heat loss. What are the thoughts on using an oil that is not soluble in propane. If the refrigerant doesn't pick up as much oil from the compressor because it doesn't mix with it, I would think that's a good thing right? And I would think that the oil separator would work better. There are a bunch of "I thinks" in the last paragraph. I've got allot more studying to do. Thanks for all the feedback guys. |

|

|

|

|

|

|