|

|

|

#311 |

|

Master EcoRenovator

Join Date: Mar 2014

Location: Florissant, Colorado

Posts: 599

Thanks: 814

Thanked 59 Times in 55 Posts

|

http://www.taco-hvac.com/uploads/Fil...ves003-008.pdf

Updated code Code:

/********************************************************

*

* ARDUINO Taco 008 Flow.

*

* In Setup, Source & Load pumps are set OFF

* , read Source pump static pressure, convert to Feet of Head & save

* , read Load pump static pressure, convert to Feet of Head & save

*

* In Void Loop, Source & Load pumps are set ON

* , read Source pump ON pressure , convert to Feet of Head

* , calculate Source pump Delta pressure (ON - OFF)

* , estimate Source pump GPM

*

* , read Load pump ON pressure , convert to Feet of Head

* , calculate Load pump Delta pressure (ON - OFF)

* , estimate Load pump GPM

* Repeat

*

*

* Change History:

* 01/27/15 Coded

*

*

*

********************************************************/

#if defined(ARDUINO) && ARDUINO >= 100

#include "Arduino.h"

#else

#include "WProgram.h"

#endif

#include <Wire.h>

#include <LCD.h>

#include <LiquidCrystal_I2C.h>

#define DEBUG 1

//#define DEBUG 0

#define I2C_ADDR 0x3F // <<----- Add your address here. Find it from I2C Scanner

//D3

#define BACKLIGHT_PIN 3 //define LCD digital pins

#define En_pin 2

#define Rw_pin 1 //can't use D0 & D1 Tx, Rx

#define Rs_pin 0

#define D4_pin 4

#define D5_pin 5 //can use D2 -> D12 below in code

#define D6_pin 6

#define D7_pin 7

LiquidCrystal_I2C lcd(I2C_ADDR,En_pin,Rw_pin,Rs_pin,D4_pin,D5_pin,D6_pin,D7_pin);

#define SDA A4 //RESERVE I2C for LCD

#define SCL A5

// pinMode(A0, OUTPUT); //This works acording

// http://arduino.cc/en/Tutorial/AnalogInputPins

// digitalWrite(A0, HIGH); //

#define Source_Pump_relay_pin 2 // D2 Buffer tank Pump Relay D1102 2.5A

#define Load_Pump_relay_pin 3 // D3 Buffer tank Pump Relay D1102 2.5A

#define Source_pump_sensor_pin A0 //

#define Load_pump_sensor_pin A1 //

float Src_on_head, Load_on_head;

float Src_on_delta_head, Load_on_delta_head;

float Src_off_head, Load_off_head;

float Src_on_flow, Load_on_flow;

int I, W, Y;

void setup(void) //Start Setup

{

pinMode (Source_pump_sensor_pin, INPUT);

pinMode (Load_pump_sensor_pin, INPUT);

pinMode (Source_Pump_relay_pin, OUTPUT);

pinMode (Load_Pump_relay_pin, OUTPUT);

// Serial.begin(9600); // start serial communication

// delay(10000); //time to enable monitor window

// Serial.println(F("........Hello world!......."));

// delay(100);

lcd.begin (16,2); // <<----- My LCD is 16x2

lcd.clear();

//Switch on the backlight

lcd.setBacklightPin(BACKLIGHT_PIN,POSITIVE);

lcd.setBacklight(HIGH);

lcd.clear();

lcd.home (); // go home

lcd.print(F("008 FLOW"));

delay(10000);

if(DEBUG)

{

lcd.clear();

lcd.home (); // go home

lcd.print(F("DEBUG = ON"));

delay(10000);

}

else

{

lcd.clear();

lcd.home (); // go home

lcd.print(F("DEBUG = OFF"));

delay(10000);

}

digitalWrite (Source_Pump_relay_pin, HIGH); //Source Pump OFF

digitalWrite (Load_Pump_relay_pin, HIGH); //Load Pump OFF

delay(10000);

W = analogRead(Source_pump_sensor_pin); //read Src pump off pressure

if(DEBUG){ W = 500;}

Src_off_head = convert_raw_sensor_to_head(W);

lcd.clear();

lcd.home (); // go home

lcd.print(F("SRC_PUMP_OFF_HD"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Src_off_head);

lcd.print(F(" Feet"));

delay(10000);

W = analogRead(Load_pump_sensor_pin); //read Load pump off pressure

if(DEBUG){ W = 500;}

Load_off_head = convert_raw_sensor_to_head(W);

lcd.clear();

lcd.home (); // go home

lcd.print(F("LOAD_PUMP_OFF_HD"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Load_off_head);

lcd.print(F(" Feet"));

delay(10000);

} //end setup

void loop ()

{

digitalWrite (Source_Pump_relay_pin, LOW); //Source Pump ON

digitalWrite (Load_Pump_relay_pin, LOW); //Load Pump ON

delay(10000);

W = analogRead(Source_pump_sensor_pin); //read Src pump ON pressure

if(DEBUG){ W = 600;}

Src_on_head = convert_raw_sensor_to_head(W);

lcd.clear();

lcd.home (); // go home

lcd.print(F("SRC_PUMP_ON_HD"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Src_on_head);

lcd.print(F(" Feet"));

delay(10000);

Src_on_delta_head = Src_on_head - Src_off_head;

lcd.clear();

lcd.home (); // go home

lcd.print(F("SRC_PUMP_ON_DLT"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Src_on_delta_head);

lcd.print(F(" Feet"));

delay(10000);

Src_on_flow = estimate_008_flow(Src_on_delta_head);

if (Src_on_flow == -1)

{

lcd.clear();

lcd.home (); // go home

lcd.print(F("SRC_DELTA_HD_NG"));

lcd.setCursor(0,1);

lcd.print(F("HANG_FOREVER_1"));

do{Y = Y;} while (Y == Y); //hang forever

}

lcd.clear();

lcd.home (); // go home

lcd.print(F("SRC_P_ON_FLOW"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Src_on_flow);

lcd.print(F(" GPM"));

delay(10000);

W = analogRead(Load_pump_sensor_pin); //read Load pump ON pressure

if(DEBUG){ W = 650;}

Load_on_head = convert_raw_sensor_to_head(W);

lcd.clear();

lcd.home (); // go home

lcd.print(F("LOAD_PUMP_ON_HD"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Load_on_head);

lcd.print(F(" Feet"));

delay(10000);

Load_on_delta_head = Load_on_head - Load_off_head;

lcd.clear();

lcd.home (); // go home

lcd.print(F("LOAD_PUMP_ON_DLT"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Load_on_delta_head);

lcd.print(F(" Feet"));

delay(10000);

Load_on_flow = estimate_008_flow(Load_on_delta_head);

if (Load_on_flow == -1)

{

lcd.clear();

lcd.home (); // go home

lcd.print(F("LOAD_DELTA_HD_NG"));

lcd.setCursor(0,1);

lcd.print(F("HANG_FOREVER_2"));

do{Y = Y;} while (Y == Y); //hang forever

}

lcd.clear();

lcd.home (); // go home

lcd.print(F("LOAD_P_ON_FLOW"));

lcd.setCursor(0,1);

lcd.print(F("= "));

lcd.print(Load_on_flow);

lcd.print(F(" GPM"));

delay(10000);

} //end forever loop

float convert_raw_sensor_to_head(float Raw)

{

//Pressure sensor output .5v = 0 PSI, 4.5v = 30 PSI

//analogRead results .5v = 102, 4.5v = 921

#define PSI_0 102

#define PSI_30 921

#define PSI_max 30

#define Convert_psi_to_head 2.31

return ((((Raw - PSI_0) / (PSI_30 - PSI_0)) * PSI_max) * Convert_psi_to_head);

}

float estimate_008_flow(float Delta_head)

{

/*

* http://www.taco-hvac.com/uploads/Fil...ves003-008.pdf

*

* Pretty tricky array usage, the array element values (feet of head)

* are taken from the Taco 008 pump performance curve Y-axis

* at each GPM along X-axis,

* array index is whole GPM along X-axis

*

* Flow in GPM is returned to caller after interpolation between

* whole GPM values along X-axis,

* or ERROR is returned (-1) if "out of array bounds"

* ie. not between array highest & lowest head values

*

*/

#define Array_size 16

float Array_008 [Array_size] = {15.25,15.05,14.8,14.35,13.75,13.15,12.35,

11.3,10.4,9.15,7.8,6.45,4.8,3.1,1.3, -1.0};

float Val, Next_val, Span, GPM;

if ((Delta_head < Array_008[0]) && (Delta_head > 0)) //Bounds check

{

// in bounds, continue

for (I=0; I< Array_size; I++) //Scan array to find where Delta_head falls

{

Val = Array_008[I]; //get array value

Next_val = Array_008[I+1]; //get Next array value

Span = Val - Next_val; //Calc Span

if((Delta_head <= Val) && (Delta_head >= Next_val)){break;}

} //end for loop when Delta_head falls between elements, I = whole GPM

GPM = (I + ((Val - Delta_head) / Span)); //interpolate to get decimals

return (GPM); // return GPM

} //end if in bounds

else {return (-1);} // error return, out of bounds

} // end of estimate_008_flow

Last edited by buffalobillpatrick; 01-28-15 at 12:03 PM.. |

|

|

|

|

|

#312 |

|

Apprentice EcoRenovator

Join Date: May 2011

Location: Tortosa, Spain

Posts: 221

Thanks: 2

Thanked 81 Times in 46 Posts

|

Did this project ever advance any further?

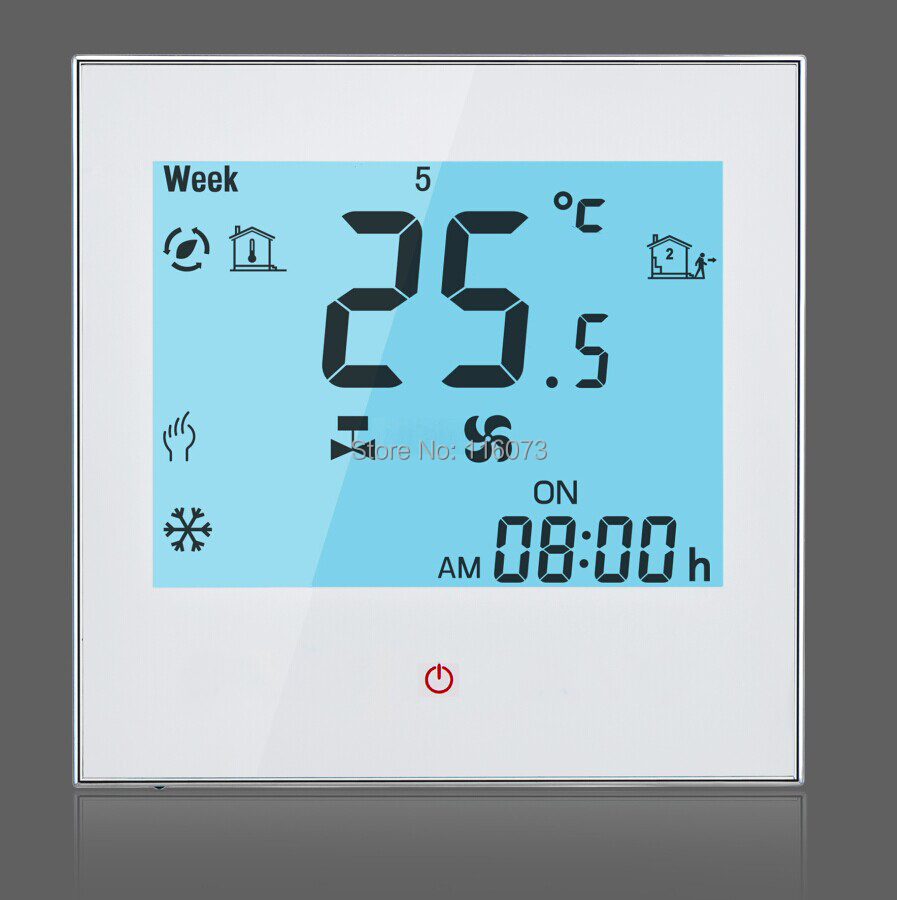

I'm just finishing off my own heatpump controller that has many of the features originally listed plus a few more. Although a home made thermometer and display is 'cool' I wanted something a bit more professional looking so after much hunting around found a device called a BAC 1000 that:

After starting the controller (which used an Arduino UNO) I quickly ran out of space so upgraded o a Mega. I also quickly discovered that for all the functionality I wanted to include a single threaded program was not going to work. A bit of investigation into real time operating systems and I came across NilRTOS which had been ported to the Arduino and was perfect for my needs. If there is interest I'll start a new thread with the design, the pitfalls and what I have ended up with. Acuario p.s. For AC - using the RTOS is finally going to give me the platform to continue with the inverter project that I still have sitting in my workshop. |

|

|

|

| The Following User Says Thank You to Acuario For This Useful Post: | AC_Hacker (11-15-15) |

|

|

#313 |

|

Supreme EcoRenovator

|

Aquario,

Yes please share. Too much info is better than not enough. I don't hate you for going with a mega dev board, at least it has an atmega chip in it still. A few others did the same. |

|

|

|

| The Following User Says Thank You to jeff5may For This Useful Post: | AC_Hacker (11-15-15) |

|

|

#314 |

|

FNG

Join Date: Jul 2015

Location: Washington

Posts: 71

Thanks: 8

Thanked 19 Times in 13 Posts

|

I hadn't seen this thread until now. Looks like you guys have been busy and have some good ideas here.

|

|

|

|

|

|

#315 |

|

Journeyman EcoRenovator

Join Date: Oct 2011

Location: Cincinnati ohio

Posts: 338

Thanks: 40

Thanked 35 Times in 31 Posts

|

So I didn't read every page of this but I skimmed through it.. Looks like we have a lot of great ideas to put into a controller. I'm not sure if this idea was covered but it seems like a common theme was running out of space on the boards. My idea is what if we had 2-3 different boards. Ie one that controlled just the compressor and the super heat and the defrost cycle and maybe a few other things that you might want to control directly related to the operation on the compressor and the refrigerant. Then have another one that was basically the thermostat that would send a signal to the other board on the compressor and that board would then turn compressor on and keep it running at its best.

Not sure if that makes sense or not |

|

|

|

|

|

#316 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

My original idea was less involved than yours. The original idea would leave the superheat regulation to a TXV. And the Uno would monitor a few temperature set points, and cut power to the compressor when these setpoints were reached. I envisioned a couple of LEDs to indicate status. The original idea spun out of control when sophisticated menu-driven LCD display was added which require more pinouts than were available (more programming to). Later, after the gumption was gone, the idea of using I2C to communicate with the display was floated. I wanted to keep it all to an Arduino Uno because of the low price and very easy availability of hardware and experience. I have spoken to some very experienced programmers since then and they all said that an Uno would have plenty of power for such a project. My idea would also require a room thermostat of some sort, like your idea. If you have any ideas of how it could be done, it is still a missing link in the DIY heat pump chain. It would be off tremendous help to many people. Best, -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#317 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

I am shocked that I missed your offer to sart another thread using the RTOS. By all means have at it! Do you have links to RTOS? -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#318 |

|

Supreme EcoRenovator

|

Guys,

The one I put together acts just like a wall thermostat. It runs off a single 1wire sensor. Modes: off, heat, cool, auto. outputs: fan, compressor, rv. The only thing it don't do is defrost. I have room for more sensors, and plan to make it do defrost for a window shaker conversion. It uses an uno board, an lcd keypad shield, and a relay shield. Works for me using the hacktronix libraries. |

|

|

|

|

|

#319 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

By the way, what is "rv"? Recreational Vehicle?? -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#320 |

|

Journeyman EcoRenovator

Join Date: Oct 2011

Location: Cincinnati ohio

Posts: 338

Thanks: 40

Thanked 35 Times in 31 Posts

|

Reversing valve?

|

|

|

|

|

|

|