|

|

|

#21 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

As soon as I get some script working, I'll post it with some comment lines.

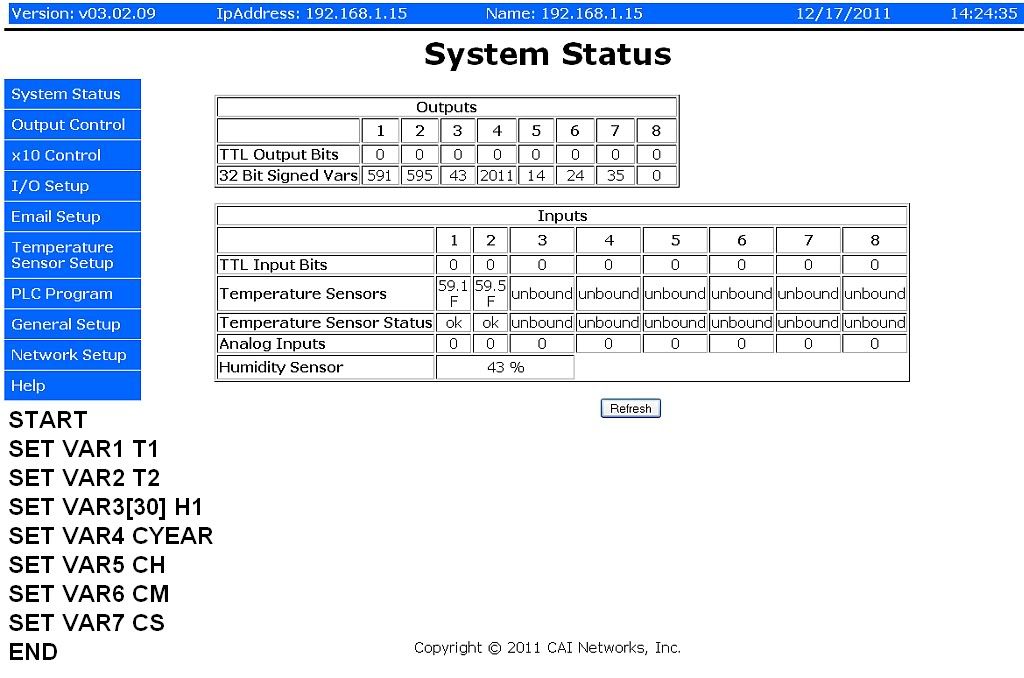

As of now, I haven't saved any of the testing stuff and over-wrote it with more of the same. You can type in the lines of code, click the load button to run it, then edit it, right in the CAI User interface. (Which is Non-volatile). But, if you short the reset jumper, then it's all gone.. The 'incessant polling' is good when you are trying out new code. It instantly shows your results, with having to hit the Refresh button. I turned polling on and off and tried to see if it caused any slow down on my fast Fios router, and didn't notice any affect at all. I did put a big cap across the +5 terminals and it did not help with the LSB Dithering. I'm not sure that more load on the PS will help or not. We'll see. I was doing that 'binning' thing in PLC and it seemed to work okay. But since it uses delays, it eats up time. I think reading those 8 temperature sensors is going hog the most time, and that will be a factor in deciding the number of time delays I'll be using in the code. I'm not very interested in floating point. My needs can be fulfilled by the crude whole numbers. 20 C, 21 C and so on..  If the LSB dithering is < 1.0, then I'm golden..  Goal: I want to display everything useful gathered from the sensors, any resultant calculations/statuses & etc on the stock CAI status page. I don't think I'll want to gather data over the long term. At the most, I can just set the email function to send me the status page http://i46.photobucket.com/albums/f1...slot/temps.jpg Once every half hour for a day or two.. Then mine the data from the email. If the 8 displayed 32 bit signed vars isn't enough, I can rotate in more data, 7 words at a time, by using an ID flag in bin 1. Hopefully I won't have to do that. I want to keep it simple as possible. Don't want my wife to consult a real big chart to interpret the page..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. Last edited by Xringer; 12-14-11 at 02:02 PM.. |

|

|

|

|

|

#22 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

This is to show some of the syntax of the PLC code.

START SET VAR1 T1 'sets var1 to temp seen by sensor 1 SET VAR2 T2 'sets var2 to temp seen by sensor 2 SET VAR3[30] H1 'sets var3 to humidity SET VAR4 CYEAR 'sets var4 to Current Year SET VAR5 CH 'sets var5 to Current Hour (from RTC) SET VAR6 CM 'sets var6 to Current Min SET VAR7 CS 'sets var7 to Current Sec END The "VAR3[30] " is an attempt to smooth the Humidity LSBs dithering effects.. Didn't really see anything encouraging, watching in polling mode. But, the delays will likely work fine when being run in a real program, where decision jumps are made based on sensor values detected.. The wait number in brackets [msec of wait] is going to force the fetch, of the highest number that pops out of the sensor, During the wait time period. Looking at the neat way the RTC (time & date) bytes can be used individually, I think it's going to be super easy to set up timed functions, like once-a-day, once-an-hour & etc. CD Current date mm/dd/yyyy format CT Current time hh:mm:ss format CDW Current day of week CH Current hour of day CM Current minute of hour CS Current second of minute CDAY Current day of month CMONTH Current month of year CYEAR Current year

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#23 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

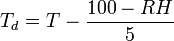

Dew point - Wikipedia, the free encyclopedia START SUB 100 H1 VAR5 ' subtract humidity(from sensor) from 100 & save in VAR5 DIV VAR5 5 VAR6 ' Divide VAR5 by 5 & save in VAR6 DIV T2 10 VAR2 'convert temp (from sensor) into two digits & save in VAR2 SUB VAR2 VAR6 VAR7 ' Put Td into VAR7 for display END At 40% & 14C, it looks like my basement's Dew Point is roughly 2 deg C.. But, not quite.. "This approach will be accurate to within about ±1 °C as long as the relative humidity is above 50%."

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#24 |

|

Lurking Renovator

Join Date: Feb 2012

Location: Atlanta

Posts: 1

Thanks: 0

Thanked 0 Times in 0 Posts

|

I would like to be able to monitor relative humidity in more than 1 place. Has anyone seen a project using a different sensor than the HIH-4000. Probably using digital inputs. I have been looking at sensors on ebay such as DHT11, DHT22. Just wondering if this can be done with the cai board or if I need to use an arduino.

Gordon Last edited by gmacie; 03-05-12 at 12:15 PM.. |

|

|

|

|

|

#25 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

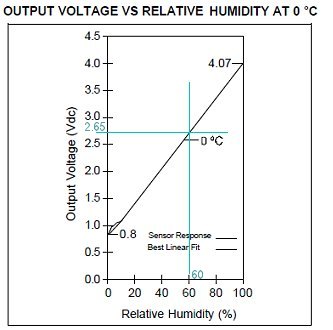

The CAI board has a built-in routine for the Honeywell HIH-4000-001 sensor that I obtained off Ebay.

So, the CAI is basically configured for a single RH sensor. However, I'm not real sure about the accuracy of this type of sensor, used with the CAI board, since they tell you it might have to be calibrated by adding a pot to the sensor output. I think any calibration that I want to do will be done within my own programming. Anyways, the CAI board has three other analog inputs, that could easily be used with an analog sensor like the Honeywell HIH-4000 type.. The output of these Honeywell sensors seems to be very linear.  From: Weather Station - Temperature & Humidity After trying to calibrate my new weather station's RH a few times, I'm starting to feel it's pretty much a lost cause for me.. Just a general indication of the RH is going to have to work for me.. I don't have the time (or interest) to keep tweaking the settings when it drifts off a bit..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#26 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Heard about this app last year, before I got my iPhone 4..

WC8RC Remote Control - YouTube Not sure if I would like to use it, since I've got a lot of PCs around here...

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#27 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

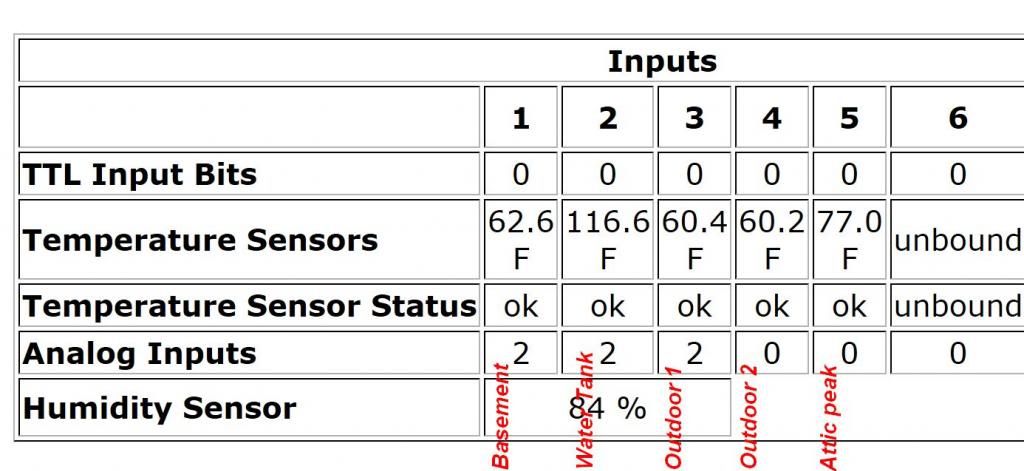

Using this program to control a fresh-air fan, installed in June 2013.

http://ecorenovator.org/forum/30357-post44.html Replaced the timer with an X10 appliance switch. The program checks the outdoor humidity and if it's not too high, a command will be sent to the X10 module, to turn on the fan. START SET OP2 1 DELAY 6000 SET OP2 0 SET VAR1 T1[300] SET VAR2 T2[300] SET VAR3 T3[200] SET VAR4 H1[200] SET RAM7 0 SET VAR7 0 MUL CH 60 RAM8 ADD RAM8 CM VAR8 CALLSUB CALLER END CALLER: TSTLE CH 8 END TSTGT H1[200] 79 CALLSUB FAN_OFF TSTLE H1[200] 76 CALLSUB FAN_ON RET FAN_ON: X10 2 7 ON SET OP1 1 SET RAM7 900 CALLSUB TIME10 SET RAM7 0 RET FAN_OFF: X10 2 7 OFF SET OP1 0 SET RAM7 900 CALLSUB TIME10 SET RAM7 0 RET TIME10: SET VAR7 0 MIDEE: DELAY 1000 TSTEQ VAR7 RAM7 RET INC VAR7 GOTO MIDEE

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#28 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

It's a long cable run, so I'm not sure how well it's going to work.. So far it's looking good.. The other sensors are close to the CAI board in a small three leg star config. But the cable run to the attic looks like about 60 feet long! It's exactly the kind of configuration they advise you not to use..

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

#29 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

I deviated from the advisories in my setup, and I have had no problem. However, when I did the first power up, my sensors were scrambled and some didn't register, so I think I was nearing the point of bad functionality. Second powerup, everything fell into line. I'd say just hook it up and try it, if it works you're in luck. If it doesn't work, it's not too hard to change a star setup to a serial set up. If it still doesn't work, your 1-wire documentation specifies a resistor that should be used on the last (most distant) sensor node. Good Luck! -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#30 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

URLs for fetching temps & RH

Five temp sensors 192.168.1.15/gett1.cgi 192.168.1.15/gett2.cgi 192.168.1.15/gett3.cgi 192.168.1.15/gett4.cgi 192.168.1.15/gett5.cgi RH sensor 192.168.1.15/geth1.cgi

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

|