|

|

|

#1151 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

Hydrocarbon gasses that you want to keep are very much more dense than any non-condensible you are likely to find in the bottle. Leaving the bottle overnight and then very slowly cracking the valve to purge out the top part of the bottle will likely rid you of 99.9% of them before you even start decanting. The trick is to make sure you don't disturb the bottle so the layers can stratify. You will need to limit the rate you pull the propane from the bottle, but certainly the theory is sound. What you are doing is effectively fractional distillation. The R290 for heatpumps thread has quite a bit of information on water and propane. It's not quite as easy to separate as you might think, particularly if you live in a country like mine where negative temperatures only happen in deep freeze units. |

|

|

|

|

| The Following User Says Thank You to BradC For This Useful Post: | buffalobillpatrick  (05-18-14) (05-18-14) |

|

|

#1152 | |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

). Also at this temperature propane will be very "lazy" to evaporate. After you start pulling propane it will keep itself cold so you can put kenguru back into freezer ). Also at this temperature propane will be very "lazy" to evaporate. After you start pulling propane it will keep itself cold so you can put kenguru back into freezer  . .It is almost impossible to get pure R290 at home, but we will get close enough. |

|

|

|

|

| The Following User Says Thank You to Vlad For This Useful Post: | buffalobillpatrick  (05-18-14) (05-18-14) |

|

|

#1153 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

We don't keep 'roo in the freezer. It gets quite gamey the longer you keep it, so shoot it and eat it fresh. |

|

|

|

|

| The Following User Says Thank You to BradC For This Useful Post: | buffalobillpatrick  (05-18-14) (05-18-14) |

|

|

#1154 |

|

Lurking Renovator

Join Date: Feb 2012

Location: Greece

Posts: 13

Thanks: 3

Thanked 3 Times in 2 Posts

|

I finally got hold of the compressor for the heat pump project :

Compressor (Model - Type) : YZG-39RCT1 - Rotary Power rating (W) : 1300 Cooling capacity (W - BTU/h) : 3900 - 13310 Displacement (Cm3/rev) : 23.4 EER (w/w) : 3.10 Refrigerant (Type - Kg) : R22 - 1.03 It has two cap tubes in parallel and a 220v operated reversing (4 Way) valve (Sorry but cannot post photos till my sixth post! Available though to my photo album) @ Vlad, Since I'm going to use it both for heating and cooling, I would need to install 2 TXV' s, if it is to replace the cap tubes, correct? (This would increase the cost and complexity of it) My HVAC friend also insists on a LP + HP differential safety switch which I am going to install, having in mint the water HX pressure limit to prevent any rupture. My intention was also, to test the heat pump with R22 and then replace it with propane, but you said that finally you will go directly to propane, why is that? @AC_Hacker I don't want to spoil your "inner warmth" but here it is still cold - raining - snowing - blowing etc, one of the worst winters (in many aspects) for Greece, we hope for a better spring and summer. I have in mind two possible configurations about the expansion / fill tank + circ. pump set-up for the ground loop (mine consists of 6 circuits in parallel of about 75m each) : - Open tank (barrel) with submersible pump (ease of construction but hight consumption) - Sealed Exp. tank with a 50w / 5m head central heating pump (More difficult to construct but with low consumption) What would you suggest ? |

|

|

|

|

|

#1155 | |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Quote:

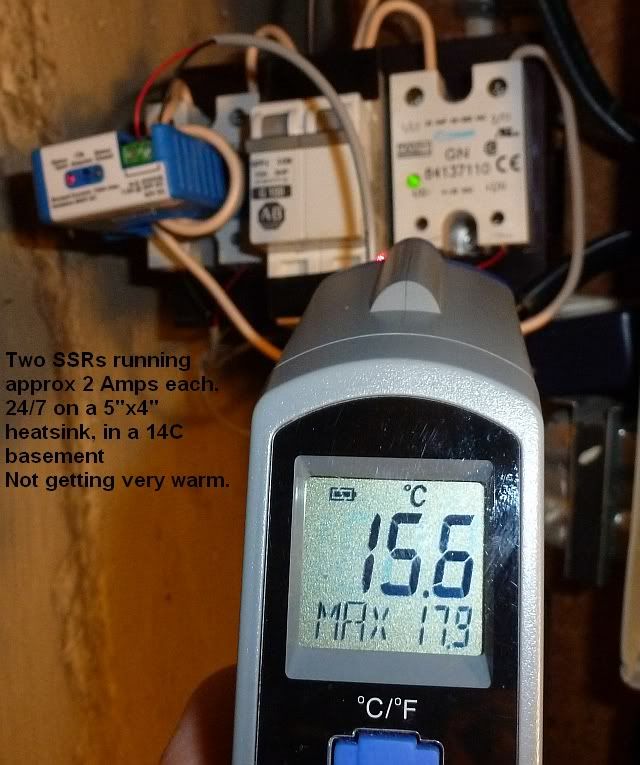

I've been using SSRs on my Sanyo ASHPs and they don't seem to heat up their heat sinks much at all. Slightly warm to the touch maybe.. SSR:  Maybe it's just too cool in my basement for the heat sink to store much heat.?. The back side of the sink has some short cooling fins. Even in summer, I don't think a fan will ever be needed in this application. When it's really cold, the typical current increases to 4 or 5 amps. But, the heat sink never really gets much warmer than it is this morning.. Sanyo #2 uses a single SSR mounted to it's sheet metal chassis. http://i46.photobucket.com/albums/f1...CL/afterBH.jpg Heat Scan during the late summer showed no noticeable heat increase. I guess the chassis is too large and has too much air flow to warm up. EMR: (Before hack) http://i46.photobucket.com/albums/f1...L/BeforeBH.jpg We do get current surges up to 10 amps. Anything above 10A triggers the sensor and shuts down the system for about 60 seconds. Anyone thinking of using R290 should consider using SSRs, instead of relays. Unless the relays are considered safe to use in a propane-air environment. I'm not an expert, but it just seems like common sense to avoid sparks with some gases.

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. Last edited by Xringer; 03-01-12 at 07:16 AM.. Reason: R290 |

|

|

|

|

|

|

#1156 | ||||

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

Quote:

Quote:

" LP + HP differential safety switch" sounds new. Can you provide more details? Quote:

. .Last edited by Vlad; 03-02-12 at 02:13 AM.. |

||||

|

|

|

|

|

#1157 |

|

Lurking Renovator

Join Date: Feb 2012

Location: Greece

Posts: 13

Thanks: 3

Thanked 3 Times in 2 Posts

|

Yes checked it twice. It seems to be the standard for the low range split type A/C here. Very easy to integrate it to my existing controls.

I meant something like what BradC is suggesting for both the High and Low Side. Sorry for my incomplete HVAC jargon! |

|

|

|

|

|

#1158 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

The homemade shop 2T GSHP was swaped out for the larger 3.5T. As some may remember I had built a small 2T GSHP that didn't produce enough heat for my liking in the shop but I had another 3.5 ton compressor, nearly new and constructed but another one around that. Now its a little premature but I'm thinking its not much better GRR!!. Drawing more current but dosen't seem to be liberating much heat. The ground loop is 6 Deg C and its sucking back 9.5 Amps @ 214V. The 2 T would maintain an average temp 17 Deg. C in the shop drawing 6 Amp. outside -8 Deg C. A little tuning maybe. And we will have to wait for a bit of a cold snap. A 4 hr test run raised the shop from 13 to 17 degree C. with an outside temp of 4 Deg. C.

Randen |

|

|

|

|

|

#1159 | |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Quote:

and that seems logical for units that are also sold in countries where only 220vac is available. In the USA, it's common for a 240vac laundry drier to use half the circuit to power it's 120vac motor, while the heating elements use 240v. I don't think that type of setup would work in some 220v countries, where the ground is just that, a ground and not the 'N' side for two 120v lines. Please correct me, if I'm wrong about this. I've never used 220 appliances while overseas.

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. |

|

|

|

|

|

|

#1160 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

Perhaps it's your heat exchanger? Did you scale up your heat exchanger by 2x? Did you increase your loop flow rate by 2x? ...just saying... -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

| Tags |

| air conditioner, diy, gshp, heat pump, homemade |

|

|