|

|

Advanced Search | |||||||

|

|

|

Thread Tools | Display Modes |

|

|

#21 |

|

Less usage=Cheaper bills

Join Date: Nov 2010

Location: Minneapolis, MN

Posts: 940

Thanks: 41

Thanked 117 Times in 91 Posts

|

To answer two questions on this thread, when you expand liquid propane into a gas, it gets very cold. If you pull it at a high enough rate the tank will feel cold. I learned when running a 100,000BTUhr garage heater with a 20 lb tank that the propane gets too cold to evaporate the gas quick enough from the tank.

"Can I use a 30 lb tank on its side? will that create sloshing? Is it best to have the opening upwards?" Propane tanks are made to be standing upright. If on its side you will be feeding liquid instead of gas into the regulator. The regulator is designed to work with the gas sourced from the evapoated non-liquid propane at top of the tank. |

|

|

|

|

|

#22 |

|

Lurking Renovator

Join Date: May 2014

Location: Ontario

Posts: 12

Thanks: 1

Thanked 0 Times in 0 Posts

|

Thanks MN renovator. I was thinking of placing the a 30lb tank on it's side on the back of the tractor. Seems to work for forklifts, but their tanks do seem to have a port that is off center... And they seem expensive!

|

|

|

|

|

|

#23 |

|

Supreme EcoRenovator

Join Date: Oct 2008

Location: Austin, TX

Posts: 1,154

Thanks: 14

Thanked 257 Times in 241 Posts

|

Some propane regulators are designed to handle liquid. In an engine application, the vaporizing propane cools the air/fuel mixture and gives a boost in horsepower and/or efficiency.

__________________

To my surprise, shortly after Naomi Wu gave me a bit of fame for making good use of solar power, Allie Moore got really jealous of her... |

|

|

|

|

|

#24 | |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

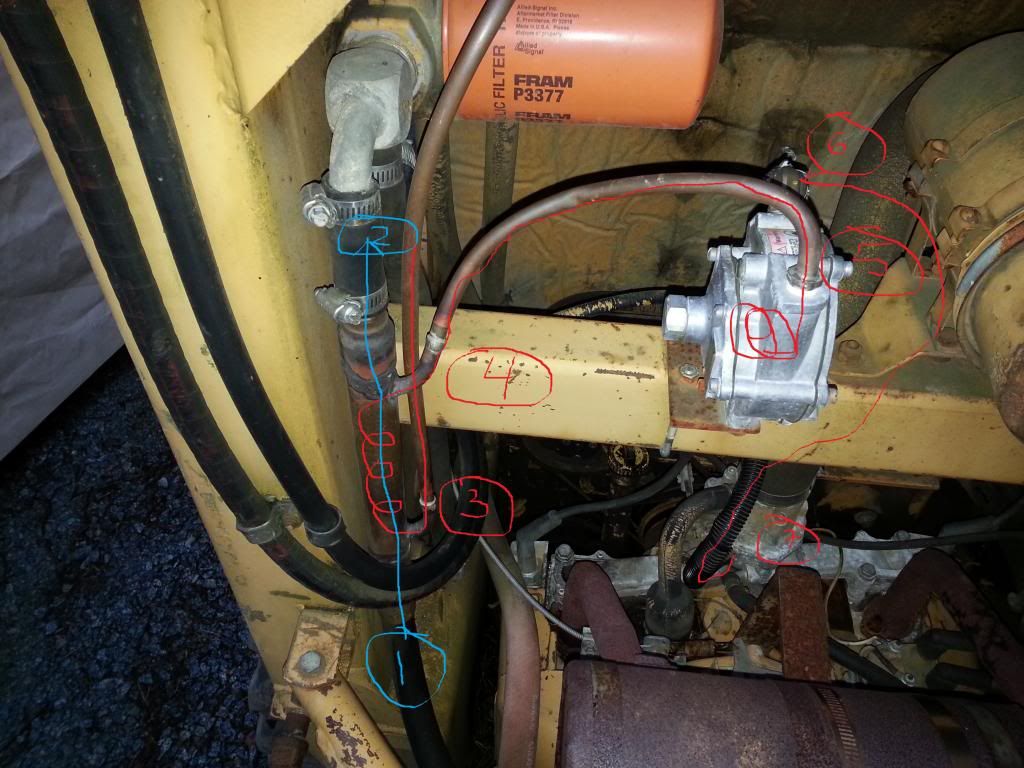

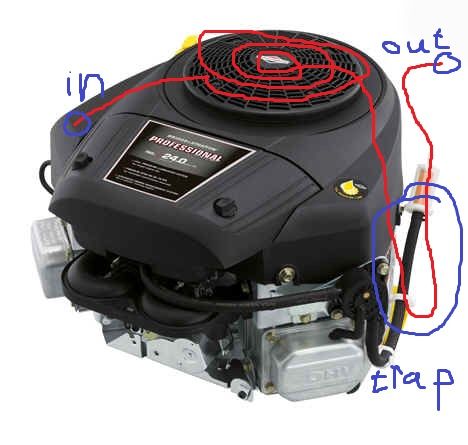

Sorry for delay... life.... Here are some pictures of my loader conversion. I will add links to amazon drive they are full resolution pics. All components and critical points are numbered the same name. I will mention this numbers and you can just look at pictures to clarify. Please don't break this post. I will let you know when I am done. Thanks..... #1 is a tank. I tried BBQ tank and it worked. I use forklift one because I buy propane by liters as auto propane and not by weight. This way I only pay for what I buy. The other reason this tank is big and aluminum and heats up quicker then steel BBQ one. You withdraw a lot of vapor propane and tank freezes up. Original forklift tank feeds liquid propane I had to switch fill and feed connectors.  https://www.amazon.com/clouddrive/sh...Rsghxn5plTqeiM #2 Here is a electric 12v fuel lock solenoid  https://www.amazon.com/clouddrive/sh...QIcvBeduC8eH_4 Here is closer look. I used beam t50 regulator which can only handle vapor propane. My propane tank is in vertical position but even then if I had 3/4 full propane was slashing inside and some liquid was getting to the regulator. Regulator was freezing up. Because my tractor is air cooled there was a dilemma for me how to heat up liquid splashed propane to make it vaporize before it gets to the regulator. I built very easy and basic heat exchanger from 2 copper tubes and couple of fittings. The inner tube is 3/4 copper outside is 1" copper. I used hydraulic oil as a heat source. It is perfect not to cold not to hot. Blue #1 hydraulic oil inlet to heat exchanger inner tube (3/4" copper) and blue #2 is hydraulic oil outlet. Red #3 propane vapor/liquid mix in (1" copper outer tube). Red #4 propane vapor (only vapor all liquid vaporized) out to regulator (#5). Now here is your problem. Your engine is air cooled and has no hydraulics. In this case I would coil 3/8 soft copper tubing (refrigeration grade and not cheap paper thin junk !!!) into 6-8 inch coil (10-15 feet lenth) and place in at engine fan air intake. You can make a "snail" coil start 8" and keep coiling up and inside. Don't make it flat. Luquid propane will get there and start "climbing up" and evaporating. Feed this coil from the bottom and get vapor from top. In this case you will have huge air flow which will warm up coil and evaporate propane inside it (unless outside is -40 degree F). I would avoid using engine heat or exhaust heat. They can be too hot.  https://www.amazon.com/clouddrive/sh...T7AoKFXLMVUDkg #6 exit from regulator goes to MAX restrictor (made of brass T and a bolt with nut)  https://www.amazon.com/clouddrive/sh...Rgwkyjx339nVcI #7 carburetor entrance  https://www.amazon.com/clouddrive/sh...TZolglfcVqSsyI Carb from top (vertical carb top is air from air filter). Marked GAS is gasoline emulsifier tube. Marked PROP is a brass tube (1/4 inch) vapor propane feed from regulator. I had to drill carburetor wall to add this tube. I used JB weld. #7 connection is outside tube barb.  https://www.amazon.com/clouddrive/sh...Txsm3Cts49yzGw This oil was changed last year and has 100+ hours. Engine is not in perfect shape. Cylinder walls are pitted from corrosion (water damaged from previous owner). When I used gasoline, oil was like a tar in 2 hours.....  https://www.amazon.com/clouddrive/sh...SdIngzrZmDdiE0 This is more or less all. Please comment..... Last edited by Vlad; 05-12-14 at 05:34 PM.. |

|

|

|

|

| The Following User Says Thank You to Vlad For This Useful Post: | mangler (05-13-14) |

|

|

#25 |

|

Lurking Renovator

Join Date: May 2014

Location: Ontario

Posts: 12

Thanks: 1

Thanked 0 Times in 0 Posts

|

Thanks for the detailed post Vlad. Your oil looks nice and clean

I would like to avoid drilling my carb as it is a new machine, and I don't want to void the warranty. I think I will be using an aluminum spacer with a side feed. Any experience with those? The coil for evaporation sounds like a pretty good idea. I might rig up something with spare aluminum heat sinks from computers. Agree it's best to stay away from bolting to engine or exhaust, sounds like a rattle waiting to happen. Do you have brand/model preference for a low cost, bullet proof zero governor? My engine is 24hp twin Briggs and Stratton. |

|

|

|

|

|

#26 | |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

To me it only takes 10 minutes to make my own  . I usually use 3/16" tube for 5-6 HP engines and 1/4" tube for 12-16 HP engines. I just braze a piece of barb to its end to make rubber hose happy . I usually use 3/16" tube for 5-6 HP engines and 1/4" tube for 12-16 HP engines. I just braze a piece of barb to its end to make rubber hose happy  Then I drill a hole in the same plane as gas emulsifier tube but on side where I find a good spot for drilling. I use permatex cold weld (much quicker than JB weld) to glue tube into carb. I do understand warranty issue with new engine. Then I drill a hole in the same plane as gas emulsifier tube but on side where I find a good spot for drilling. I use permatex cold weld (much quicker than JB weld) to glue tube into carb. I do understand warranty issue with new engine. I would use just 3/8 copper tube but long enough for "evaporator". Make sure propane needs to "climb up". Liquid will stay on the bottom and vapor will get "uphill". You can also use a trick called in refrigeration liquid trap. After your "evaporator" from it's top you run your tube down to a warm (not too hot) place(you can find warm air flow after cooling engine. Just try to find it by moving your arm when engine is hot) and then run it up to your regulator. This trap will "kill" the rest of vapor.  I used empco KN, woodward 50, Beam 50 Beam 60. They all work great. Make sure you get one with primer even manual one is OK. Once I got a great deal on eBay. I bought a bunch of woodward 50 (as same as as Beam). I paid something like $20 each. I converted my lawnmower(6.5HP Briggs), wood chipper (9HP honda, water pump 3.5 HP old Briggs, drilling rig 15 HP China honda clone, Pressure washer 15 HP China clone) They all work perfect. Last edited by Vlad; 05-13-14 at 03:14 AM.. |

|

|

|

|

|

|

#27 |

|

Lurking Renovator

Join Date: May 2014

Location: Ontario

Posts: 12

Thanks: 1

Thanked 0 Times in 0 Posts

|

Given this evaporator coil business, the kn looks like a winner (if I can find the space). I think I would rather deal with low pressure for the coil and trap (my brazing skills are soso). When we say high pressure, how many psig are we talking?

|

|

|

|

|

|

#28 | |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

If you look at my diagram closely you will find that coil goes first and then first stage (which is built-in regulator). KN is low pressure. You need to add first stage pressure regulator before. Propane pressure you can expect up to 250 PSI. If your brazing skills are so so buy Silfos 15 brazing rod. You can braze copper to copper without flux and you will need "Handy Flux" for copper to brass joints. Use propane torch or map gas. Silfos 15 is so easy to use even monkey can do it  Brazed copper tubing is used on new high pressure refrigeration systems (800 PSI) and they vibrate 24/7/365 on compressors. Woodward 50, Beam 50 Beam 60 are 2 stage regulators, so you feed them directly high pressure vapor after your evaporator coil.... You can actually find a small coil from refrigeration equipment and use it. You just need to find a right size. Last edited by Vlad; 05-13-14 at 05:50 PM.. |

|

|

|

|

|

|

#29 |

|

Lurking Renovator

Join Date: May 2014

Location: Ontario

Posts: 12

Thanks: 1

Thanked 0 Times in 0 Posts

|

Thanks Vlad, very helpful.

Good tips on the Silfos 15 rods. Now all I need is a monkey... I suspect I will have a hard time finding a coil small enough on an old refrigeration unit. But I will keep an eye out. Since this is a brand new unit, I think I will run it on gas for a while and get a feel for "normal" operation and other things (like idle speed). It will help to tune when I switch to propane. Last question, I suspect the copper tubing I need is NOT the soft coils sold at the home hardware stores? If not, where is a good place to get the good stuff? |

|

|

|

|

|

#30 | |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

Refrigeration tubing is called ACR tubing and measured by OD and not an ID like water pipes. The wall thickness is about 0.03"+- The problem with thin wall tubing is it is hard to bend it without kinking. If I need full coil 50' I buy at local refrigeration supply store. If I need 5-10 feet I usually buy at Home Hardware (Canadian) near my house. Just buy a few sticks of silfos 15 and try it. It flows like butter and sticks to copper. It doesn't run like water if you overheat it (solder likes to do this). Also you can fill gaps with no problem. You don't even need to clean up your copper tubes unless they are green from oxidation....  Last edited by Vlad; 05-14-14 at 03:18 AM.. |

|

|

|

|

|

|

|