|

|

|

#121 |

|

Helper EcoRenovator

Join Date: Mar 2010

Location: South Jersey

Posts: 57

Thanks: 42

Thanked 17 Times in 11 Posts

|

I see a peak of 231w output of my M215 inverters. using a 260 watt panel

|

|

|

|

|

|

#122 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

Ben - again very nice videos. I also love the easy set up using the enphase toolbox on my smart phone.

Here are a few suggestions. The debate on enphase M215 vs 250 microinverters will quickly end in 2017 as they are being phased out. The two year old S280 (280 watts) and new IQ 6 series (60 and 72 panel; 290 watts) is being shipped now. Don't date your superb video with quickly out of date issues. Here is how I work out microinverter choices - calculate the cost per watt. The latest series of the M215 will make 235 watts. On my roof, they will do this for hours and it is not just a "peak" for a couple minutes. Your saw the same 235 W output. But the M250 is 250 watts MAXIMUM, no more. Right now (April 2017), the costs for the two are about $75 for the M215 and about $95 for the M250. The current cost per watt is $0.32 for the M215 and $0.38 for the M250. You may not think this is big, but on a system, it quickly adds up. The same calculation metric is appropriate for the 280 and new IQ6 - look at the cost per watt. The second issue is the real life output of the panels. Sadly, I see people putting up 260 watt panels with M250s. This is a waste. The lab or STC panel output may be 260 watts, but the PTC or real life output is ~ 90% of that. Thus, a 260 watt panel in real life puts out only 234 watts - a perfect match for a M215 and a waste for the more expensive M250. You alluded to the advantage of the enphase microinverter as if one panel is shaded, then the whole string is not compromised. Me thinks you need to mention more specifically the downside of string inverters. One shaded panel, on a string inverter, means that panel becomes a current sink - a resistor. And the superb enphase software allows you to look at each and every panel and inverter. Then figure in the 25 year NO prorated guarantee (via Siemens) for the inverters. One of my customers just had me replace bad M190's. That series had problems. We shipped them back and they replaced them with M215's at NO cost (and free return shipping as well for the bad units). Very impressive. I have been told that others installers have not even had to send the bad M190s back as enphase can look and see on their software that they are bad. Not all utilities will accept the well made and superb Midnight turn off switch. I bought one such Midnight switch for a customer install and had to eat the cost as the utility INSISTED on a manual turn off lock out disconnect switch. Yes, I showed then the lock out portion of the Midnight switch, but some utilities are VERY conservative. You may want to mention in your video of asking the utility if they will accept this Midnight switch (your utility will, Bravo for them!). In your situation, with a very constrained roof area, you may want to suck it up and go with the more expensive S280 and 320 W panels. This would boost your output by ~ 20%. Lastly, the new enphase IQ series microinverters will require a new Envoy that are NOT compatible with the older microinverters. The new IQ trunk cable only has two wires and is cheaper. The effective distance for transmission to the new Envoy will also be a lot longer as the signal will not be on the noisy neutral lead, but somehow on the 240 V system. I have been told as far as 1500 feet (500 meters). I also expect to see an IQ7 (they just released for sale in North America the IQ6 with 290 watts) with 320 watts of power for a price per watt in the low $0.30 range by 2018. That is the stated enphase goal - a "smartphone sized" inverter with 97-98% efficiency in the 300+ watt range, compatible with 60 and 72 panel systems for about $0.30 per watt. Yowza! That does not help you now. For you right now, I would look at a choice between an M215 based system (260 or so watt panels) or the S280 inverter with 320-340 watt panels with a 20% larger power output. But you are going to pay 20% more for the larger system . . . but for a constrained roof size, you may want to pay the extra 20% for 20% more power. Budget, budget - I know!! Renvu.com is your friend. The weekly specials are great. Again, GREAT videos! Steve ps thanks to pinball a couple years ago that told me about Renvu. Before that I was using another solar warehouse that was (and is) not nearly so good in terms of price, delivery and support If you do call Renvu, feel free to say I recommended them - this has gotten discounts for others! Do not be afraid to dicker as I regularly get discounts for trunk cable. For example, they will give me free "extra" drops to account for the necessary length going from one rack to another. Just gotta ask . . . Make SURE to tell them of your videos and sent them a link.

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 Last edited by stevehull; 04-14-17 at 01:33 PM.. |

|

|

|

| The Following User Says Thank You to stevehull For This Useful Post: | jeff5may (04-09-17) |

|

|

#123 |

|

Home-Wrecker

Join Date: Sep 2008

Location: SE Wisconsin

Posts: 546

Thanks: 3

Thanked 165 Times in 96 Posts

|

Steve Hull, I'm sending you a private message. Hope you can help.

__________________

To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#124 |

|

Administrator

Join Date: Aug 2008

Location: Germantown, WI

Posts: 5,525

Thanks: 1,162

Thanked 374 Times in 305 Posts

|

Sounds fun to me. Give me a call when you know when you'll be doing it.

__________________

Current project - To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. & To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#125 |

|

Home-Wrecker

Join Date: Sep 2008

Location: SE Wisconsin

Posts: 546

Thanks: 3

Thanked 165 Times in 96 Posts

|

What's the best way to attach a junction box to my solar racking?

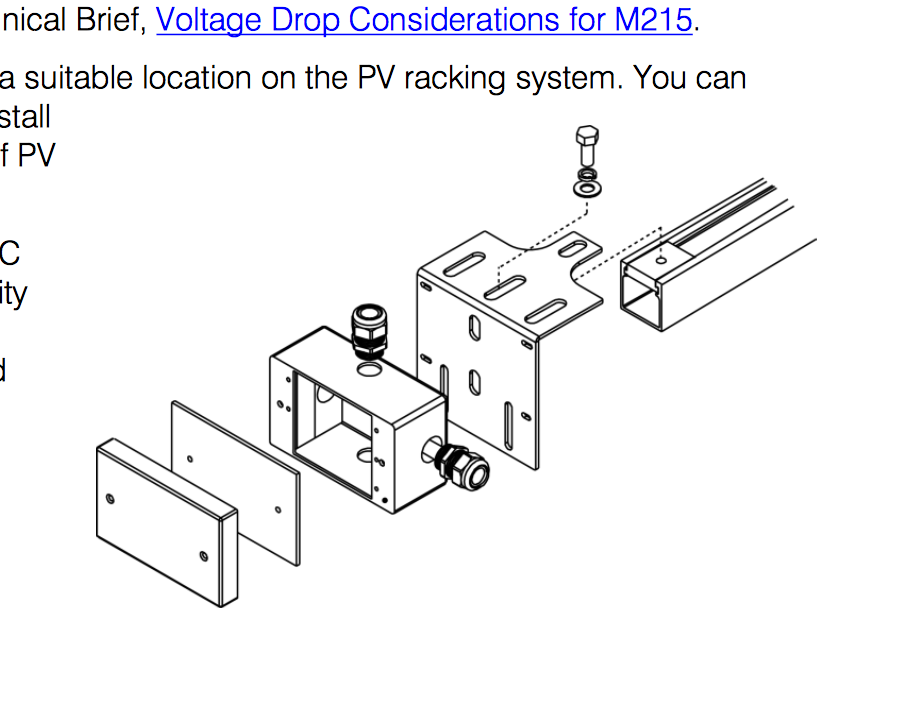

In the Enphase manuals, it shows a right-angle bracket to attach a junction box to the end of a piece of racking. I HAVE NO IDEA WHAT YOU ACTUALLY CALL THIS BRACKET. There's no Enphase part number next to it, and I can't seem to find anything similar on solar supplier web pages or at my local electrical supply place. Anyone know what to call this and where to get one, or other good ways to connect a junction box to racking?

__________________

To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#126 |

|

Supreme EcoRenovator

|

J Box to superstrut or unistrut mounting bracket should work.

EMBK50-001: no longer available. When they were available, they were 16 bucks each. Here's a kit with that bracket, some wire and a sealing cap for the string:  http://www.nooutage.com/ekit-01-001.htm Whew! Not cheap. Last edited by jeff5may; 04-13-17 at 07:44 AM.. |

|

|

|

|

|

#127 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

Ben,

The enphase "solution" for this string junction box is just WAY too complicated. We came up with a simple, inexpensive and quickly constructed junction box that uses plastic 6x6x4 inch electric junction boxes (Lowes, HD, Menards) with simple inexpensive weatherproof cable compression fittings to bring in the respective trunk cables and the one output 240 V line. Total cost < $20. The boxes are easy to drill with wood paddle bits and the fittings seal really well. Actually, we now use a "punch" to knock out the holes - faster and cleaner than drilling. If there is any gap, then a bit of RTV silicone caulk seals it up. The lid screws down with a weather tight gasket. Inside the junction box, we connect the respective leads (two trunk lines and output romex) with brass compression bolts and then thoroughly wrap each connection with high quality (3-M) plastic adhesive electric tape. The 12 G romex goes into conduit down to the combiner box where there are circuit breakers for each 20 A string. Then a larger G wire to the disconnect switch. Recall that each trunk line has four wires and a smaller box (4x4x4 inch) is just too tight in terms of space. We always use a mid string trunk feed to prevent voltage rise on the microinverters and put the junction box under one of the mid string panels. The plastic box is attached with self tapping screws to the aluminum racking rails. In the very unlikely event that the junction box ever needs service, then you tilt up the panel for access. The box is now protected from weather and UV rays. I really like to have the combiner and circuit breakers inside the structure. The enclosure is cheaper (compared to outside weatherproof) and I like it right next to the structure circuit breaker box for safety and clarity. Hope this helps. Steve

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 Last edited by stevehull; 04-13-17 at 06:07 PM.. Reason: typos |

|

|

|

|

|

#128 |

|

Super Moderator

Join Date: Jun 2013

Location: SC

Posts: 2,930

Thanks: 172

Thanked 564 Times in 463 Posts

|

I used the same boxes that Steve used almost the exact same setup. I did center tap to keep the voltage rise down. I did home runs down to the combiner box circuit breakers. That all runs to a mechanical disconnect switch close to my house meter.

My combiner and circuit breakers are inside my barn now it is about 130’ away from my house. I installed the microinverters back to back to keep the wires short to the boxes.

__________________

Current project Aquaponics system , Passive Solar Greenhouse build To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. Solar Install 12.5 Kwh- To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. Mini Split installs - To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. EV Chevy Volt - To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#129 |

|

Home-Wrecker

Join Date: Sep 2008

Location: SE Wisconsin

Posts: 546

Thanks: 3

Thanked 165 Times in 96 Posts

|

Steve, do you have any photos inside your junction boxes, or photos of how they are mounted?

You just screwed the boxes straight into the racking? So the box must be sideways and parallel to the racking then to do that. The best I can think of so far for mounting junction boxes is to get some sort of larger aluminum L, mount that to the back of the box, and then drill a hole through the other leg of the L and mount that to the rack with a bolt. It would be pretty simple and repositionable. My Combiner/Disconnect needs to be on the outside of the building, as required by the power utility. I did design this so that it's physically close to the building breaker panel (about 2 feet away) just on the other side of the wall. This allows a Utility worker to disconnect the solar even if I wasn't home and the garage was locked. (Although the safety features built into the inverters means they stop producing power just by disconnecting grid power to the building.) The detached garage is 25' from my house, and there's a direct line of sight between the main utility meter and where the solar disconnect will be. As for Voltage Rise, it looks like it's really an issue when you max out a string. With the Enphase inverters, I could have 16 (17 w M215 inverters) in a string. It's that total current in series that causes the problem. Since I will have three rows of 8 panels, having a combiner box at the end of two of the rows, (where both rows go into one box) I've just center-fed a string of 16 down to two legs of 8. Half the current now means one quarter the losses. This also physically puts the combiner box at the END of the row. If I ever need to get to that combiner box again, it would be accessible from the end of the roof via a ladder. The box could be either right on the end, or under the end panel. I like the idea of it being under the panel in terms of protection from the elements AND looks. I like the idea of it NOT being under a panel because I'm pretty sure I never want to ever have to take off any of these solar panels ever again. The third row of panels would just be it's own string. That gives me one circuit of 8 panels, and one circuit of 16 panels (but center fed on the Enphase cable.) My combiner box has space for three circuit breakers. This gives me room for expansion. For example, I might be able to put a couple solar panels in the back yard. (I don't have ideal solar back there, but I might for example put up a couple "EXTRA" panels with cheap salvaged inverters.) One other thing that I've thought of is that I guess I'm not exactly sure of requirements for supporting conduit. I know it has to be spaced off the roof. (Mostly to keep the roof from heating the conduit.) My racking will be running horizontal, and the conduit connecting the strings of solar will need to run vertical. I suppose the easiest way to support it is just to have it run over the top of the racking. Racking will be about every three feet. I could use a conduit strap straight to a bolt into the top of the racking. However, I couldn't have the conduit go over the racking where ever there is the top or bottom end of a solar panel. I could go over the racking at the ENDs of the rack, where the racking extends past the solar panels. (The racking needs to be wider than the solar panels by at least one inch minimum on either end for the panel end clamps. I can always make it a little longer as needed.) Any thoughts on plastic versus metal conduit? I noticed that on my house, the service entrance, and anywhere else that has conduit is plastic. Plastic never rusts. It is floppier than metal. I will also need a piece of conduit that bends around the edge of my roof to get the conduit down the wall to the disconnect. Metal conduit can be bent, but I think it that case, I'll be going beyond the "180 Rule" and will need a pulling body anyways, so several plastic parts glued together should probably work just fine to make the "Get off the Roof" bend.

__________________

To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 0 or greater. You currently have 0 posts. |

|

|

|

|

|

#130 |

|

Steve Hull

Join Date: Dec 2012

Location: hilly, tree covered Arcadia, OK USA

Posts: 826

Thanks: 241

Thanked 165 Times in 123 Posts

|

I have no problems mounting the junction box under a panel. That is what I did to protect it and to provide easy access through the roof.

Voltage rise is not all or none. It is progressive and the mid string minimizes the voltage rise. I even use a mid string then I only have a 8 panel string (4 panels on each side). The efficiency rise is small, but multiplied over years, and with modules, it really adds up. I hate conduit on a roof - metal or PVC. In your case, it will only be partially visible, but it looks REALLY ugly. It also gets uglier as you look at it longer. Yes, if you do mount conduit on the rood you need have have PVC stand offs - which require drilling through the roof . . . So I prefer to go straight through the roof, from the bottom of the junction box, with PVC. Then I run PVC conduit inside the structure where it is protected from UV. The electric type gray PVC is resistant to UV, but it is not impervious. I mount a 3/4 inch PVC screw type male onto the bottom of the plastic 6x6x4 junction box. That connects to the plastic conduit. With your beautiful roof, I would not use surface mount conduit. Yes, this means holes through the roof, but when protected by the panel, and well caulked, it is just not an issue.

__________________

consulting on geothermal heating/cooling & rational energy use since 1990 |

|

|

|

|

| Tags |

| diy, garage, heated slab, pex, solar |

|

|