|

|

|

#1131 | |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Add my 2 Window A/C's with Cap tubes, and a 7KW reverse cycle ducted heat pump that originally had a fixed piston orifice and now has an EEV.

Quote:

For DIY it is almost perfect solution, but with limitations. Like for indoor use legal charge in Canada must be less then 350 gram. In the US a have no idea. |

|

|

|

|

|

|

#1132 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

What I found about R290 is bits and pieces here and there. There is no even an accepted name for this refrigerant. They are R22a, R290, Propane, all kinds of "greens..." and "enviro..." etc. Also there is a bunch of blends of propane and butane.

The technical details are also differ from site to site. If we could share our own experience and known info this would help to summarize list of properties. What I found (again some info can be controversial) is 1 R22a = R290 = pure refrigerant grade propane, which is dry and scent is added for safety reason. 2 R22 PT chart almost = propane PT chart. We can simply use R22 Pt chart for simplicity and usually they are more detailed. Sorry I wanted to say R22a PT chart looks like R290 chart. But R290 chart is more complete. 3 R22 Cap tube when used with propane must be 16-20 % longer. Because propane is easy to push through the cap tube (it is like water VS alcohol) 4 Superheat MUST be in 20F zone because propane is tend to condense and compressor is getting liquid in suction line. This can dramatically shorten life of compressor. 5 I found that many recommend liquid line-suction line HX because it helps maintaining superheat and increases COP (substantially compare to R22) 6 Legal charge for indoor use in Canada 350 gram. 7 If you want to use BBQ propane, it must be dry. If you use liquid line filter/dryer it will remove moisture but WILL also REMOVE the smell from propane. 8 There is controversial information about COP. Some people say it is much more efficient compare to R22 some say COP differ but not significant. Lets put together as much info as possible about R290 and see what we can do. Also I wanted to add about charging system. Do not charge any refrigerant as a vapor because you will add non condesable gases like nitrogen into your system. Always charge liquid into suction line while compressor is running. Just be careful and meter refrigerant with your gauges. Last edited by Vlad; 02-24-12 at 05:56 AM.. |

|

|

|

|

|

#1133 | |||

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

As you can see in the video he put sight glass in suction line (I don't know why never seen before). He is asking himself why he can see droplets of refrigerant there. Yes it must be only gas there. It is how compressor is flooded. One of the reasons his compressor is flooded might be the location of txv bulb. The bulb is located above txv, charge from bulb can migrate to txv element. Also I can see bulb is located on top of the tube (must be a bit on sight) tube looks oxidized and must be cleaned to have good thermal contact. Bulb must be strapped with copper strap and not tape or plastic straps(I can' see this detail). The other major problem is evaporator coil header. As you can see top part goes directly into suction header. Quote:

He does need hard start kit for compressor. When you have cap tube system equalizes in off cycle. With txv you need extra torque to start compressor, because it is under pressure on discharge side. Quote:

Subcooling is completely different thing. It allows your system to run more efficient and it helps your MD to function properly. If you have 10F or more subcooling it means your MD is getting only liquid refrigerant and NOT GAS/LIQUID MIX. Without subcooling refrigerant will be in gas/liquid mix state. If you have factory designed system and you need to charge it. First thing is you check factory charge amount. If we changed components in your system, which is our case you need to find right amount of refrigerant. It is very tricky for cap tube because it is critically charged. It is easier for txv system because txv will take care (with limitations) of providing right superheat. Last edited by Vlad; 02-24-12 at 05:18 AM.. |

|||

|

|

|

|

|

#1134 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

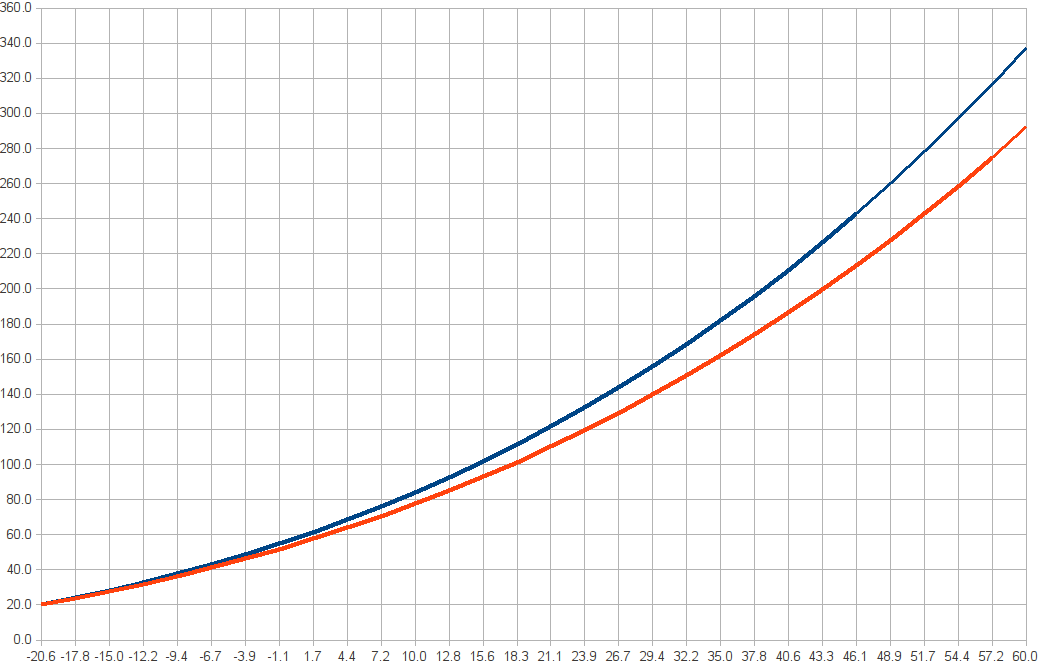

R22a is not an ASHRAE sanctioned mnemonic by any stretch and what you get in the bottle is anybody's guess. Same with Envirosafe and all the rest of the substitute blends. As for charging as a vapor, you only stand to add non-condensibles if you have them in your bottle in the first place. The stench is removed by the filter drier, however it is also removed as it seems to dissolve in mineral oil, so it stays in the compressor sump. R290 PT curve approximates R22, but the pressures are quite a bit lower. This PT has R22 in Blue and R290 in Orange. Pressure in PSI, Temp in C  Have a look at the R290 for heatpumps thread, it's got some pretty comprehensive information in it. Last edited by BradC; 02-24-12 at 05:25 AM.. |

|

|

|

|

|

|

#1135 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Sorry about posting "discouraging" details. But refrigeration systems are complicated and require more attention then most people think. If you just want to play with ac you do not need details. But if you want to build it right be ready for homework.

|

|

|

|

|

|

#1136 | ||||

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

Quote:

Quote:

Quote:

Charging as liquid is industry standard, especially with blends. Quote:

We can use R290 chart when it comes to R22a because R290 chart is more complete. Last edited by Vlad; 02-24-12 at 06:06 AM.. |

||||

|

|

|

|

|

#1137 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

Vlad

I would agree. Most of us would rather play on the side of efficiency. My first attempt at the GSHP I was very pleased with the out-come. The little 2 Ton unit is operating seemingly well. (saving a pile of cash that was destin to the fuel oil mongers) Being ground source the evaporator temps and pressures are rock steady. The condensor side as well dosen't change more than 4 Deg C. When I had tweeked the charged the unit had been operating for hours so the temps had evened out. I had used my amp probe and temp probe on the high side tube before the HX to get the temp of the liquid/gas. I was looking for the highest temp and the best current for the optimum charge. The refrigerant is propane the pressures are 45 LS 210 HS and 86 Deg. C The 2 Ton unit is a little small for the shop and I've just finished a 3.5 Ton version to swap it out and again with cap tube. I'm understanding the theory behind the TXV changing the amount of restriction based on the temp of the evaporator. Do you think I would gain more efficiency with the TXV if the temps and pressures are so steady. Even on start -ups the temps don,t change much after about 10 min. I'm at a point where I can still cut out the cap tube and replace it with a TXV. I realize we may tend to be a little barbaric in our methods as we learn hands on. But we do appreciate direction from people in the know. Thanks Vlad Randen |

|

|

|

|

|

#1138 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

In any case, properly measuring the P/T of what is in your bottle will tell you a _lot_ about the purity of what is in there. I'm investigating the fractional distillation of a Propane/Butane mix. The thing that is bolloxing me at the moment is the US has a habit of adding Methanol to propane. I'm trying to come up with a useful way of separating that, but that means I actually have to pollute Propane with Methanol to try it, as our Propane is dry enough not to warrant that level of pollution. I take our BBQ propane and circulate it through a filter/drier a couple of times and I have as close to R290 as you can mostly get. No wonder they call Australia "the lucky country". |

|

|

|

|

|

|

#1139 | ||

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 724 Times in 534 Posts

|

Quote:

Please note that a new thread called "DIY Well Drilling" has been initiated to be a repository for this important discussion. Quote:

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

||

|

|

|

| The Following User Says Thank You to AC_Hacker For This Useful Post: | Vlad (02-24-12) |

|

|

#1140 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

AC thanks for starting drilling thread. Manifesto became a monster thread . It is very hard to find something here. I will upload all info and pics about my drilling experience there.

It would be good to have some kind of summary of the project (may be separate page or thread ) not a discussion but timeline. We have many projects started here and they all mixed up together. It is almost impossible follow your project or somebody else project. People keep asking the same questions you keep re-posting.... It is just an idea. |

|

|

|

|

| Tags |

| air conditioner, diy, gshp, heat pump, homemade |

|

|