|

|

|

#51 |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

My new clamp meter arrived. Yay! Here's a quick brain dump after taking some measurements.

I have not got the flow meter properly calibrated yet (the vendor told me after I had received them that their calibration values were a best guess and had not been validated!) so my system heat output is a best guess with what I have available (evap air flow, relative humidity & temperature differences). The system power consumption hovers around 2KW. So that's ~1.4KW for the compressor, 350W for the evap fan, 200W for the water pump and the rest is control system and misc losses. I'm moving between 7000 & 8000W of heat, so my entire system COP is at worst 3.5 and at best 4.0. I throttled the HX back to get a condensation temperature approaching 50C and gained 700W of system power consumption. I've check some spec sheets for new Daikin and Fujitsu inverter systems, and the best they spec for COP is 3.4 for a 5KW unit and 3.28 for bigger unit. Calculating it out based on their detailed specifications, the COP they are specifying is for the compressor condenser units and does not appear to take into account the evap head. So, while I've spent more on the total system enhancements than I'll ever recover in power cost, I've still spent less than the cost of a new ducted inverter unit *and* I'm using less power. Now, none of this is optimised yet. The EEV is being "hand" controlled at the moment, the injection bore has ~7PSI of back pressure and I'm losing 25KPA of pressure between my suction service valve and the suction port on the compressor (~1.5K of temperature). It looks like this accumulator/reversing valve/compressor combination is at its flow limits. Hardly surprising given it was moving about 6KW of heat into a condenser at ~60C and it's now moving over 7KW of heat into a condenser at ~25C. Apparently this is common knowledge, but it's new to me : As you unload a single phase motor the power factor progressively gets worse, so while you are using less Watts your overall VA draw drops very little. I should remedy that with my next compressor condenser unit where I have a three phase compressor on a VSD. This will maintain a very good power factor under varying load conditions and allow me to trim the compressor capacity to suit the system heat load better. |

|

|

|

| The Following User Says Thank You to BradC For This Useful Post: | Roostre (01-31-18) |

|

|

#52 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

A heat pump is able to include the compressor heat energy in it's tally of useful work, but an A/C must subtract the compressor heat energy in it's tally of useful work. So, for an A/C to achieve COP of 3.5 to 4 is very impressive indeed! Keep it up! Best, -AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#53 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

I fed my actual system parameters into Coolpack (which is the excellent tool I used when designing my system from the ground up). My current compressor has an isentropic efficiency of about 0.5 (which is about right given the data I found on the Emerson web site for a tired old recip). This gives a theoretical COP of about 5.7 and a measured COP of about 5.3 (obviously *only* looking at compressor power). Moving from the recip at 0.5 to a scroll at ~0.7 should see the theoretical COP rise to in excess of 6 and measured up around 5. I'll lose another ~350W for the second fan coil, and the compressor should go from 1.4KW to about 2.2-2.5. That will give me a total consumption of about 3380W for a heat removal of about 14KW figuring a COP of about 4.1. Time will tell I suppose. If I come out with a system COP better than 3.5 I'll be jumping through flaming hoops in celebration. |

|

|

|

|

|

|

#54 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

I'll even send you some cake & ice cream, but I'll not be able to guarantee their condition when they arrive. * * * I'd like to know more about how you are using Coolpak I found the download link HERE. And I found various tutorials HERE. So far, my design approach has been very primitive (even that might be giving myself too much credit). But with my approach, I have gotten amazing results. I think it is time to put my brain to work, assisted of course by well-developed computer modeling. If you have any tips on using this tool, I'm all ears. My motivating reason is that yesterday, I picked up a lovely 12,000 BTU (3.5 KW) ASHP outdoor unit for 35$ (US). Even though it was made in 1998 (no inverter technology and uses R22), there is no indication that it was ever actually put into service. My plan is to use it in hybrid fashion with my small GSHP & loop field... with the ASHP pulling the load in mild weather, and the GSHP taking up the slack during more severe conditions. Best, AC

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#55 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Coolpack is *brilliant*. Nothing more to say.

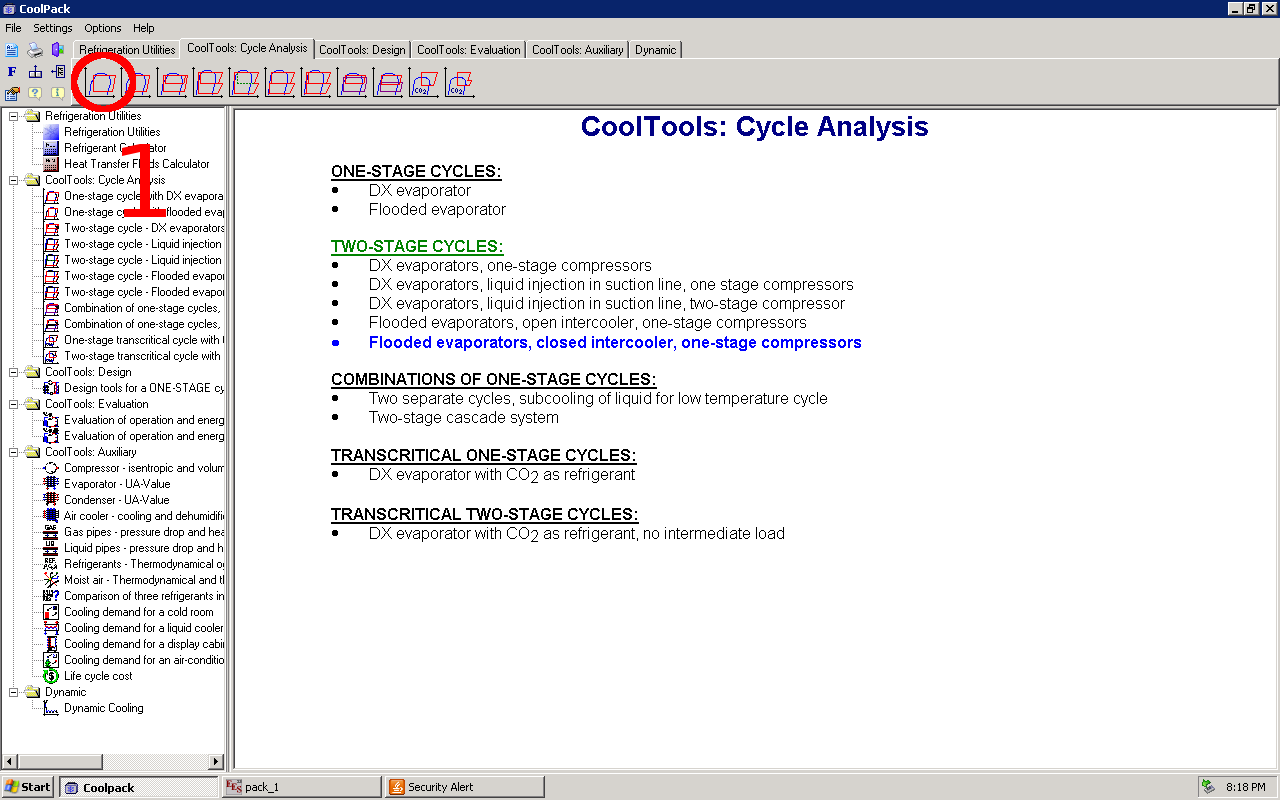

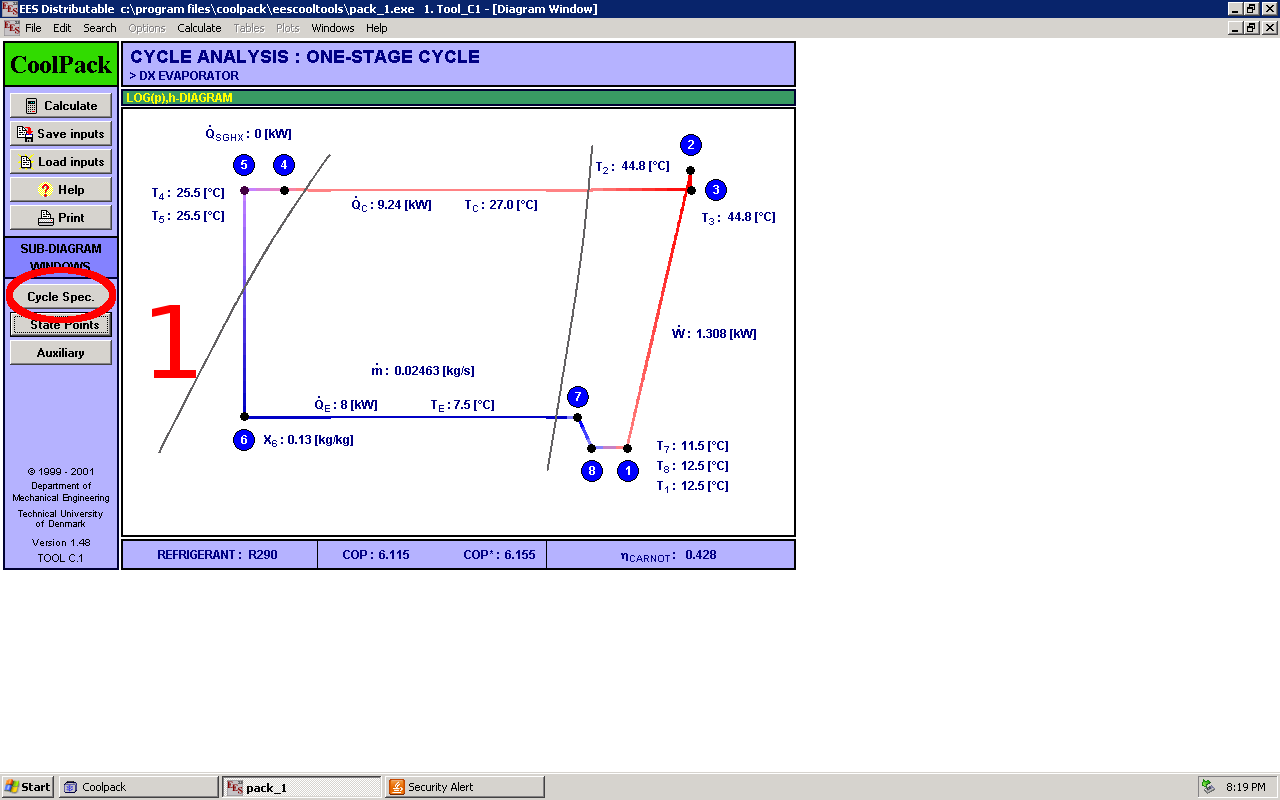

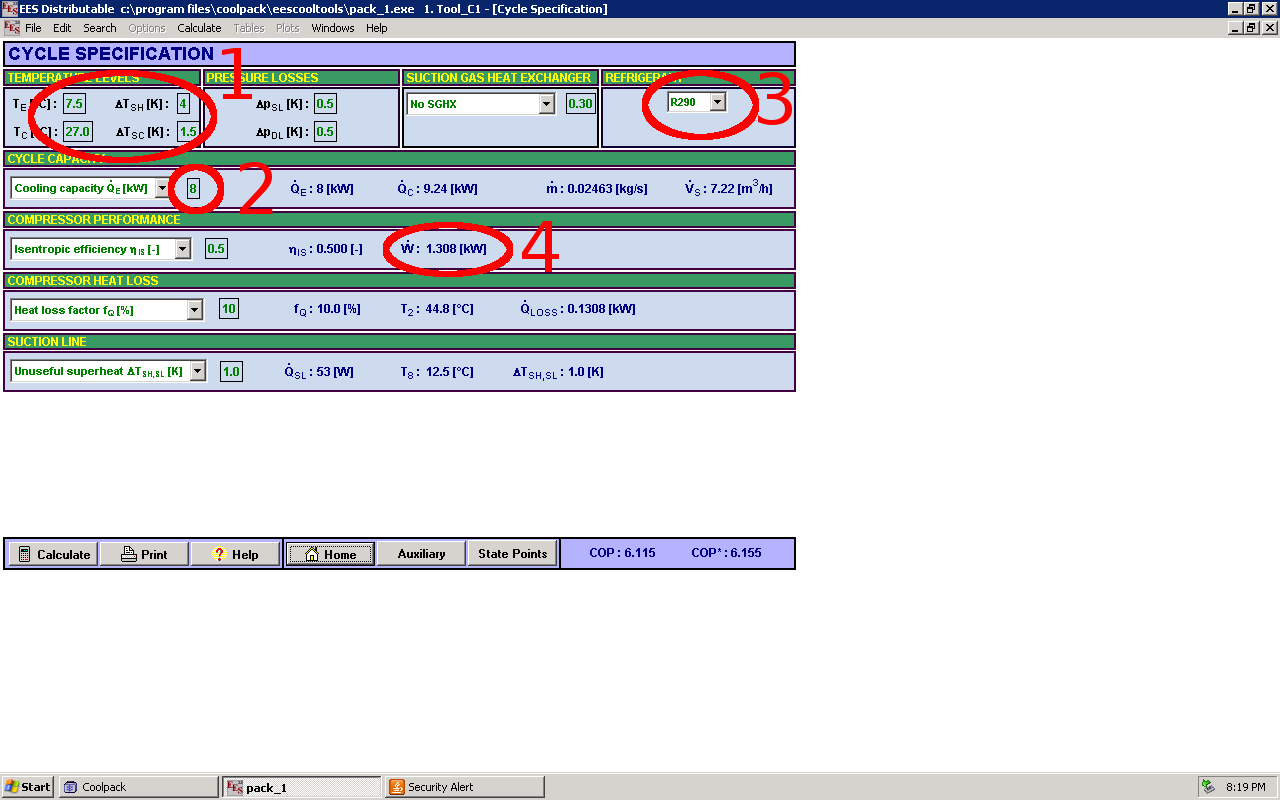

Most of my tinkering is done with the straight single stage DX simulation. It allows me to plug in the numbers I know (or want) and it'll tell me the stuff I need to know. For example : Earlier in the week, after measuring the power consumption of my system I wanted to figure out why my compressor was drawing far more power than I had originally calculated it should. I went to coolpack, loaded up the single phase DX simulation and fed it the data. Staring here :  The Single cycle DX is the circled button. Pressing that will present you with this :  Ignore the image now and just press the "Cycle Spec" button leading to this :  In no particular order : Select (3) your refrigerant Put in your guesstimated evaporation and condensation figures in (1). I've been as accurate as I can there with superheat and subcooling at the measured values. Put in your estimated cooling capacity in (2). I've selected 8KW as that is about where things sit for me. Now press the Calculate button. Result (4) tells you what it thinks your compressor power consumption should be. In my case it was way low, so I incrementally reduced the Isentropic efficiency from the default of 0.7 until the power value came out right. This ended up with what you see above (an efficiency of ~0.5). I found a chart floating around that confirmed a tired old recip probably sites around there so my figures are pretty close. Now, we can click the home button to go back to the pretty picture with the illustrated cycle. Nice huh? Have a play with the condensation temperatures and see what that does to your power consumption and COP. Now, it's up to you as to how you achieve those Te & Tc values. In my case I took my desired Tc and ran it through a spreadsheet that calculates the required size of a HX (of any kind) given the U values of each heat transfer medium (R290 & Water) and the desired LMTD. From that I calculated it would take about 8M2 of HX area to achieve my desired condensation temperature. I gave the figures to SWEP and they concurred with my calcs. I then took the HX requirements to Sondex (on the east coast) and they supplied me with an affordable HX within my specs. I plumbed it up and measured the actual values, and they are within a margin of measurement error from my prediction, so all in all a good result. To achieve my required Te value, I've had to ramp up the fan speed in the air handler to try and extract more heat from the air. It has worked to a degree anyway. There's a 30 min rundown on Coolpack. It has so many great features and cool bits I've just not remembered off the top of my head (most of my work with it was 12 months ago - my projects don't move fast). The best part is, from concept through calculation through build and measure, all the figures stack up. It's just a thermodynamic system obeying the laws of physics. If you get a result you don't expect it just means you've forgotten to take something into account! Put the measured temps & figures in from your system and see what it comes up with. In your case, I'd start with an isentropic efficiency of about 0.6 (supposedly a rotary), plug in the Te & Tc, superheat and subcooling from your measurements, and then tweak the heat load until the compressor running current is about right. Kind of working it in reverse. I'd be most interested to see your cycle chart (I'm not at all familiar with the heating side of things). Quote:

Last edited by BradC; 01-16-13 at 06:45 AM.. |

|

|

|

|

|

|

#56 |

|

Need More Eco

|

Subscribed: best thread since the manifesto.

|

|

|

|

|

|

|