|

|

|

|

|

#1 |

|

You Ain't Me

Join Date: Nov 2009

Location: Northampton MA

Posts: 662

Thanks: 6

Thanked 71 Times in 58 Posts

|

It seems to me that the #1 obstacle in building a geothermal system is the digging. Even the heat pump itself isn't too difficult as you can simply buy an pre built unit; albeit for a lot more money than one can make their own. There have been some valiant efforts on this front in the heat pump manifesto but most people there that have described their processes in any great depth have all run into various problems with getting down to great depths, such as 100 - 200 '. Let us here discuss the methods of drilling and digging at home without subbing out the work to a well driller or excavation contractor.

I will keep the first post of this thread updated as time passes with links to relevant posts and news. |

|

|

|

|

|

#2 |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 724 Times in 534 Posts

|

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

#3 |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

I wonder if DIY well diggers know they need a permit to drill??

Portable water well drilling rig, How to drill a water well |

|

|

|

|

|

#4 | |

|

Lurking Renovator

Join Date: Feb 2010

Location: Portland, OR

Posts: 27

Thanks: 0

Thanked 0 Times in 0 Posts

|

Quote:

In the state of Oregon, you need a permit and someone who is licensed as an Engineer or a well digger, but the permit costs are far less than costs for water wells. In my case I am currently an engineering intern as far as the state is concerned, and the requirements for being a state certified engineer is 4 years of working with others who are. But in my current job with Intel many are not, as certification is more for contractors who work on government contracts. My plan currently is to work with my friend who is. |

|

|

|

|

|

|

#5 |

|

Lurking Renovator

Join Date: Feb 2010

Location: Portland, OR

Posts: 27

Thanks: 0

Thanked 0 Times in 0 Posts

|

Looks like this is the place for this so here I go. If you are going to be drilling a well, by far your best choice to power your drilling platform would be a nice gas motor in the 4-8HP range which has its high RPM's geared down to produce high torque. For some people here though, having a nice reversible electric motor can bring with it some nice benefits such as noise level and reversibility which is a boon in attaching and removing drill pipe extensions. Also since this is EcoRenovator, why bring another gas engine into it

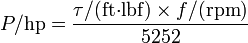

Before I get into electricity stuff, let me caution that my degree is in chemical engineering so my electrical engineering skills are a tad rusty, please feel free to correct anything that I don't get quite right here. So after much research there are a few good sources for electric motors with similar power ratings to gas, electric vehicles and treadmills. Motors for vehicles tend to be rated for the 12-24Vdc range as they are going to be run off of lead acid batteries typically, this means that for high power loadings, they are going to require very high current. 1HP is ~=750W so a 1HP motor is probably drawing ~800W from the batteries which at 12V is almost 70A! If we're going to power this off the wall outlet the power supply becomes non-trivial at these kinds of loadings. Treadmill duty motors on the other hand are normally designed to be run using ~130Vdc which makes it very easy to just run AC current out of the wall through some form of rectifier and power the motor directly. On top of that, treadmills and most other exercise equipment have the tendency to be used for a few months or so only to be forgotten and shoved into the corner when that good old American laziness sets in and there is normally a very nice selection in your local "for sale" section. And now here's the one I recently picked up. As you can see, I've found a 130Vdc motor that has a full speed of 6700RPM at at that speed draws 18A and puts out 2.5HP. Below is the conversion of horsepower to torque  From this we can see that at full speed, this motor is only putting out ~1.96 ft*lb of torque which is far too low for drilling. But if I were to gear this down at 60:1 we're now up to almost 120 ft*lb of torque at ~110RPM. That much torque will move some dirt and rocks. Now for the other components of my haul Power control board Toroidal AC choke sliding potentiometer Here's a schematic of the layout http://www.instructables.com/files/o...NMFMEG9UME.pdf |

|

|

|

|

|

#6 |

|

Lurking Renovator

Join Date: Feb 2010

Location: Portland, OR

Posts: 27

Thanks: 0

Thanked 0 Times in 0 Posts

|

Ok, so been reading up on types of controllers, and It looks like the control board is using some form of TRIAC (TRIode for Alternating Current) or SCR (Silicon Controlled Rectifier) to provide the pulse width modulated DC duty cycle to the motor. In effect, it's taking the 60Hz AC and rectifying it into 60Hz DC current pulses of a width varied by the sliding potentiometer.

Due to the fact that these controllers use relatively low frequency pulse modulation, a motor connected directly to the controller would end up with very jittery operation and thus it needs the inductor or choke to smooth this out. Inductors resist changes in current flow and will store the pulses in the form of a magnetic field. So the choke is also a must if I want smooth torque at low speeds and will help ease the strain on the motor. |

|

|

|

|

|

#7 |

|

You Ain't Me

Join Date: Nov 2009

Location: Northampton MA

Posts: 662

Thanks: 6

Thanked 71 Times in 58 Posts

|

Where I live we have an abundance of rock. In fact it some times seems like we don't really have any soil, just rock all the way down. I'm thinking that if you are either in a location such as I am or if you strike rock in you drilling you won't make it with 2.5 HP, with any torque. In the heat pump manifesto a fellow named Vlad I believe made some giant rig that was gas powered and he was using tri cone bits. As I recall he even had trouble getting down too deep and decided to only dig to 70'. He never explained why this is as far as I recall.

|

|

|

|

|

|

#8 | |

|

Lurking Renovator

Join Date: Feb 2010

Location: Portland, OR

Posts: 27

Thanks: 0

Thanked 0 Times in 0 Posts

|

Quote:

Last edited by Blauhung; 05-20-11 at 06:07 PM.. |

|

|

|

|

|

|

#9 | |

|

Journeyman EcoRenovator

Join Date: Jan 2011

Location: Seattle

Posts: 326

Thanks: 109

Thanked 23 Times in 18 Posts

|

Quote:

So at 100' it goes to rock? How many well holes do you need to dig? I have two donated treadmill motors and controllers and wonder if one could be for a clockwise rotation and the other for a counter clockwise? I am told too that my soil should be clay to sand also. Easy drilling I hope. |

|

|

|

|

|

|

#10 | |

|

Lurking Renovator

Join Date: Feb 2010

Location: Portland, OR

Posts: 27

Thanks: 0

Thanked 0 Times in 0 Posts

|

Quote:

|

|

|

|

|

|

|

|