The next size up dehumidifiers look like this when new:

The one I modified to be a turbocharged electric heater looks like this now. If you look at the right side of the evaporator coil, you can see the little silver clip that holds the defrost thermistor against the pipe:

I had to remove all kinds of styrofoam from between the covers and the working parts to assume control of the airflow through the device. I then fabricated my own out of 3/4 inch polyiso "R-board". When run as a heat pump, the condenser had a miniature squirrel cage fan (robbed from a "space-saver" microwave that served as the fume extractor for the built in range hood) that blew air downward into the cavity and out the back (compressor) side of the unit. I had cut a piece to size that fit in between the heat exchangers to split the flow of air.

As you can see, this unit has undergone a few surgeries. It no longer has a capillary tube, a thermostatic expansion valve (TXV) has taken its place. This device allows the evaporator to extract much more heat than a cap tube. It also keeps the unit from frosting up when temperatures are not close to freezing. When I replaced the cap tube, I reclaimed the R22 for future use. After the TXV mod, I filled the unit with BBQ propane to gain experience and insight with the "impossible refrigerant". In reality, it works quite well.

The compressor found in this unit is ultra common. Besides dehumidifiers, it is also used in many 5000 BTU window air conditioners. These compressors are pretty stout, and will survive a decent amount of torture. The only thing bad about them (and their big brothers, the 44Rxxx line) is that they are not built to withstand low suction pressure. So if the heat exchangers get clogged up, either by frosting up or being clogged with lint or other air blockage, the compressor will eventually cook itself to death.

This unit has a built-in thermistor for defrost sensing. The sensor is clipped onto the evaporator piping, and can be moved up or down for more or less sensitivity to frost formation. As you can see in my pic, I have my defrost sensor situated pretty low on the coil to increase cycle time.

I found that these units can be set so that they run constantly. When the evaporator frosted over, the built-in defrost stopped the compressor and ran the evaporator fan like it should. That's how i ran my unit. I had it rigged to a waterbed thermostat so that the compressor ran when the thermostat called for heat. The additional blower was wired in parallel with the compressor, so it only ran when the compressor did. The control board handled defrosting quite well on its own.

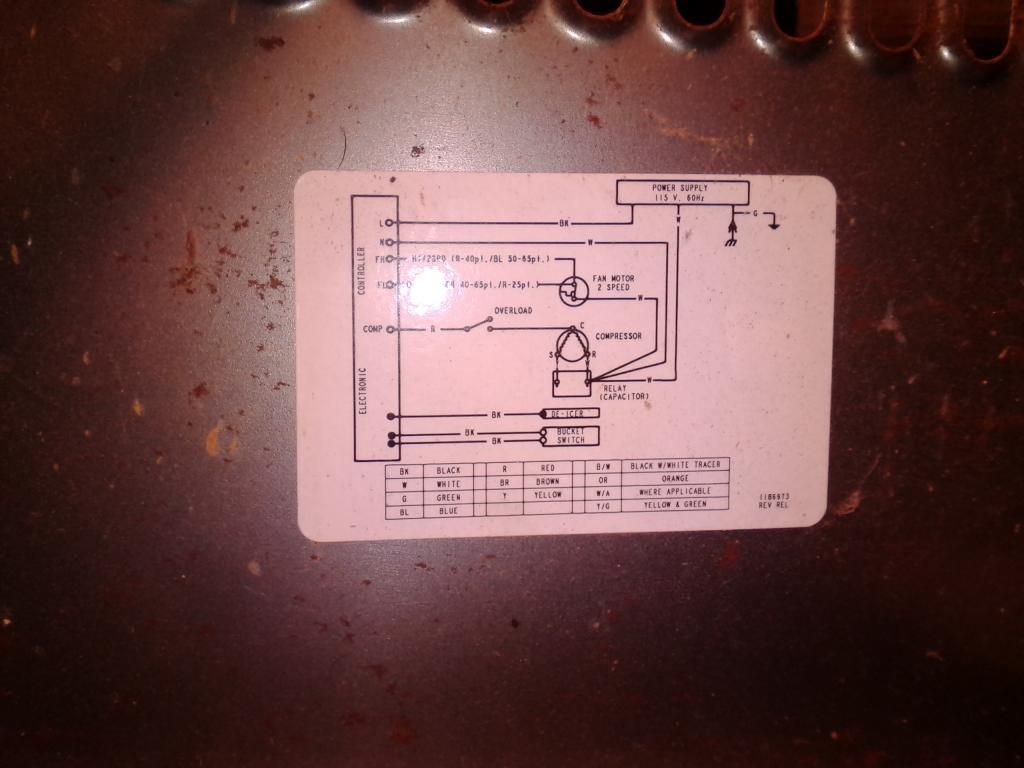

The wiring diagram on the inside of the unit cover shows that the compressor runs off the red wire from the control board. Fan high speed is orange, low speed is blue.

I was lucky with this unit: the wires have labels molded into the control panel cover! I disconnected the red wire from the control panel, and wired it to the output side of my thermostat. I then wired the terminal where the red wire connected to the input or "line" side of the waterbed thermostat. This way, the control panel would still control defrost and I could turn everything off from the control panel.

When it was acting as a heat pump, it did a better job of space heating than a space heater (that you could plug into a wall outlet) ever could. It worked great down to around 40 degF. For operation below 40degF outdoors, I rigged a little defrost "gimmick" up to the unit. A super small mag-drive pump was stuck into the bottom of a rubbermaid container, which the unit sat in. While it was doing its job, the unit weeped constantly and filled the tote. The pump outlet was run up the unit along the compressor discharge line, which heated the water somewhat. The water line was then run to the top of the evaporator, where the warmed water kept a portion of the evaporator warm. When the unit tripped its defrost, the somewhat warm water flow was enough to defrost most of the evaporator in a few minutes due to conduction in the pipes and fins. I got it to work down to about 30 degF using this method.