Quote:

Originally Posted by dremd

Not trying to make any point here; but that's my quasi scientific test results.

|

dremde, I'm not at all trying to disrespect your gauges. I'm sure your equipment is just fine.

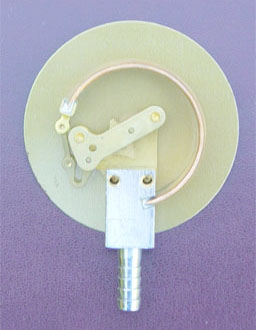

The problem is that the gauges like the kind in your photos (Bourdon type) generally have their maximum sensitivity and accuracy at mid-scale readings and are the least sensitive and accurate at the extremes. In HVAC work, some very important stuff happens at the deeper levels of vacuum. This is why the micron gauge was invented.

The specs for the Harbor Freight venturi-type gauge suggests maximum vacuum it can pull to be around a 98.4% vacuum, and for the rotary vacuum pump it is 99.995% vacuum.

Bourdon Gauge

Bourdon Gauge

The Bourdon type gauge is just not physically able to distinguish between 98.4% vacuum and 99.995% vacuum. But it is at the 99.99% end that the water flashes to vapor and is pumped out.

The issue here is the inherent limitation in the design of the Bourdon Gauge.

Here are some links regarding the micron gauge and deep vacuum in HVAC:

pulling a vacuum - HVAC-Talk: Heating, Air & Refrigeration Discussion

Pulling A Good Vacuum Equals $$$ For The Contractor - How To - Air Conditioning, Heating & Refrigeration NEWS

why use a micron gauge - Google Search

Best Regards,

-AC_HAcker