Quote:

Originally Posted by TechShop

Acuario, nice work. I don't think you need to add any frills to your web pages. That touch screen thermostat will put a nice face on the finished product.

Jeff, for the reasons you have cited, I'm an advocate of using an inexpensive PLC relay unit to do the dirty work at the heat pump as commanded by the system controller or thermostat (in this case, Arduino).

The simple ladder logic makes it possible to control a complex heat pump arrangement (compressor, pumps, fans, etc with a basic thermostat and these little PLCs can be found in the same price range as a basic Arduino.

|

For those with a distaste for ladder logic, the PLC units can be fed a program created elsewhere (on a PC) and translated to ladder. Usually the translated program is optimized during translation, so what you write may not be exactly what makes it into the PLC. Debugging or writing explicit commands into the source code is sometimes necessary.

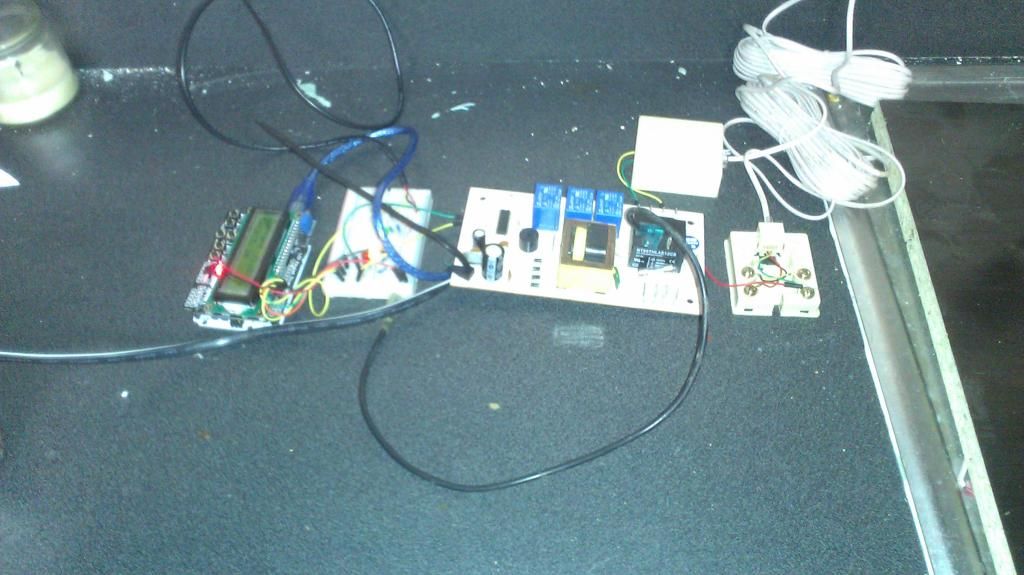

I used a "freebie" power board out of a donated portable dehumidifier for a relay shield equivalent. The board also has a regulated 5VDC power supply built into it that feeds the Uno board through the USB plug.

The board in its old home

The board connected to the Uno with LCD keypad shield

Please take note that this rig functions as a non-standard heat pump thermostat as wired. The yellow and green wires are compressor and reversing valve call, the red is the 24VAC feed to run contactors and controls inside the unit. Defrost control is handled by an ICM 315 board inside the unit. That's what I had in it before the GP controller was made.

However, these power boards are pretty much the same in every window AC or portable dehumidifier out there that has a digital readout and pushbutton control. These boards have enough relays on them that are matched to the demands of the patient unit, so all that wiring and such is already tested and proven by the OEM. To morph a unit into a heat pump, one of the fan relays could easily be rewired to control a reversing valve solenoid. For a water-source unit, a HX pump or two could run straight off a relay or two.