I have some thoughts on this

I've looked at the commercially available units (there's one on the US market), at heat recovery ventilators, energy star dehumidifiers over 100qt/day, at high drying efficiency PTACs and hospital sized AHUs.

Also I have an electric dryer vented indoors (thanks to stupidity of the previous homeowners).

my thoughts are to do this:

dryer vent --> some kind of easily cleanable (and GOOD) filtration, probably down to MERV8

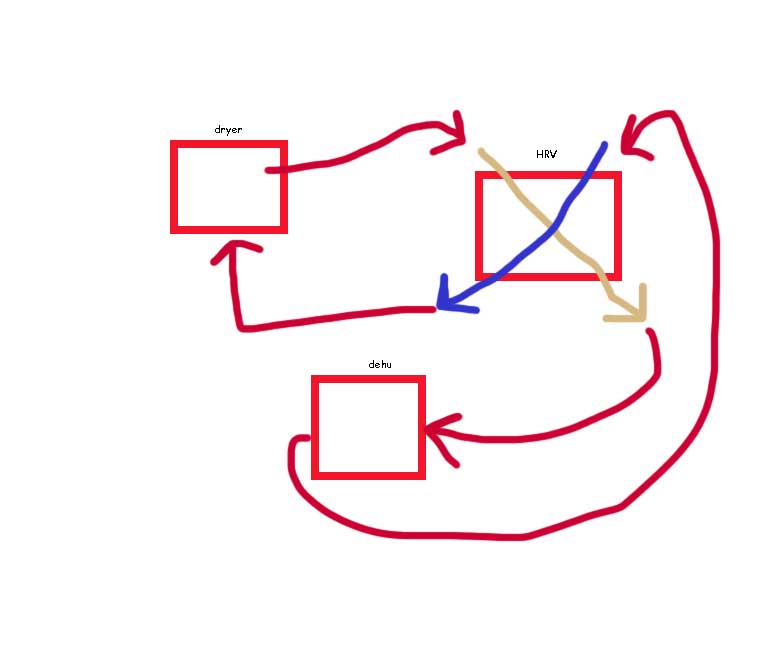

filtered air into an HRV to bypass thermal energy around the dehumidifier (so that the head pressure doesn't blow it up), and to lower the air temp to the evaporator for better performance-->into the dehu to dry and heat the air, back to the HRV to pick up the thermal energy, then into the dryer - air is just a working fluid.

like this (horrible drawing):

the problem with the unit on the market is cost (wow they cost a lot) and apparently dust fouling of the heat exchangers. they offer a heat pump only mode, as well as heater assisted mode (heat up with heater then switch to heat pump once the water is evaporating, instead of waiting for compressor waste heat to raise the temp of the water/clothing mix).

a major advantage (aside from not using resistive heat to dry clothes), is the lack of conditioned air being exhausted (and replaced) from your house. assuming a dryer moves 200CFM for 45 minutes, that's a lot of hot humid air infiltration in texas, or cold dry air infiltration in canada.