I finally bit the bullet and began brazing up copper tubing to my Brazed Plate Heat exchangers.

This brazing project that I'm sharing with you is to attach short lengths of 3/8" copper tubing to the gas ports of the heat exchangers, to which the bent refrigeration tubing will be later brazed, this will keep the heat exchangers safely away from subsequent brazing steps.

Tool set up

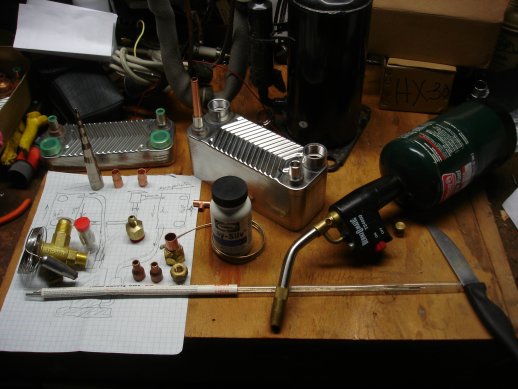

Here's a shot of most of the tools I used for this round of brazing.

On the right is my tourch, in the photo, I have the green propane bottle still on my tourch, but I have found that using MAPPS gas which comes in the yellow bottles is more expensive but very much nicer to work with. Compared to soldering, brazing results in much stronger joints than soldering but requires more heat than soldering too. In refrigeration work, you shouldn't ever consider using solder, as the vibration from the compressor will fatigue solder. I tried propane when I first started brazing, I found that it could work, but it took quite a while to get the copper to the required cherry red that is needed for proper flow in brazing, then I discovered MAPPS gas, and life is good again. I'm really sold on the piezo trigger type torch, not only because it is easy to light, but also because it is so much more convenient to turn off the torch when it is not needed. Because of this, the cylinders last much longer.

I am an insufferable tightwad and a real gas welding setup isn't in my future. If you happen to have acetylene already, that's the Cadillac setup.

In the foreground is a long tube of Siphos 5% silver rod (the HVAC trade seems to prefer Silphos 15%), that is really the greatest thing since sliced bread. If you are brazing copper to copper, it is ideal and doesn't call for any flux. It also flows really nice and is very strong.

If you are brazing dissimilar metals, you'll need to use brazing flux and high-silver (40% or more silver, I'm using 55% silver) brazing rod. Close to where the torch crosses over the Silphos tube is my little bottle of flux (also Silphos brand) and a small coil of high-silver rod. I don't braze dissimilar metals much, so the small coil ($$$) has lasted me quite a while.

Also shown in the photo are a couple of my Brazed Plate Heat Exchangers. The smaller one I got for a prior project, that is on hold and the bigger one is what I ordered for this current heap pump project.

The considerations I went through for sizing the larger exchangers

can be found here.

Frankly, I was initially hesitant to braze the exchangers because I was fearful that I would un-braze the exchangers that I had spent so much money on. Then I happened to come across a blog where a formerly frustrated HVAC guy told the new way he was doing it (thank you Al Gore for inventing the Internet!).

Rag is

saturated, not just damp.

What he did was to wrap a saturated (not just moist) rag around the heat exchanger close to the place where the brazing would happen. Another key was that he applied heat to the copper tube, got it glowing cherry red, and then moved the cherry red area down to the heat exchanger and fed in the high silver rod as he did so (he had pre-fluxed, of course). I followed his method and it worked out great.

But I started, I made up some purging tubing so that I could displace the oxygen inside of the copper tubing that would otherwise cause copper-oxide flake contamination. The purging gas most usually used in the HVAC trade is nitrogen, while carbon dioxide has been use successfully also. In fact, Daox did a test using CO2, and it worked just fine. Argon would also be good, if you have it around but it is a tad expensive. I have even heard of some mindless idiots using propane as a purging gas, but I wouldn't recommend it if you expect to live to see tomorrow.

AC_Hacker's penny-wise purging tube

Here is a shot of my purging tube, I bought some small PVC tubing and super-glued some latex tubes to the ends because the PVC was much cheaper than the latex and I am such a penny-pinching miser. The latex streatches nicely over copper tubing from 1/4 to 3/8 and worked out really well.

Purging tube with rubber band to seal in the purging gas.

So before the brazing started, I fed some purging gas through the heat exchanger until I could see it coming out... it kind of looks like a little mirage. When I saw it coming out, I waited for it to purge a bit longer, and reduced the flow of purging gas, but made sure it was still flowing.

If I had been a completely brain-dead idiot, and had used propane for my purging gas it might have looked something like this:

Please ignore flame.

...but since nobody in their right mind would actually do this, please ignore the flame.

NEXT POST: TURNING UP THE HEAT

Regards,

-AC_Hacker