Chronicling the build this post describes the converting of the air handler. This had occurred prior to the ground loop (April of 2011) The air-handler was a reclaimed unit from the scrap pile. It has two HXs one a slant-coil for air-conditioning and another for heating with hot water.

The capillary tube is removed and a water manifold is soldered in. The two HX used in tandem will only increase the capacity and efficiency. The fan is a squirrel-cage with a 3 speed motor. The motor is currently running on the lowest RPM.

The air handler was given a fresh coat of paint and hoisted to a central location on the shop ceiling and fasten. It is plumbed with a motorized valve and check valve that will eventually manage heat from the future solar (hot water collector) as well as the heated water from the GSHP.

The shop area will be heated & cooled with the air-handler. The GSHP can also supply chilled coolant to provide air-conditioning for the summer.

Coolant, I should explain. For several reasons its required. The ground loop enters the building above grade so it is possible that the exposed tube could have the liquid freeze during the cold Canadian weather when the GSHP is cycled off. The liquid could also freeze inside the GSHPs HX. Ask me how I know???

The coolant of choice is a food grade Propylene Glycol mixed with water.

The office area sports a heated concrete floor. This is indeed the holy grail of space heating. The floor can be heated using low temp. water providing a uniform comfortable heat. This was my beta test (1992 install) as I was planning to use the system for my new home in the future.

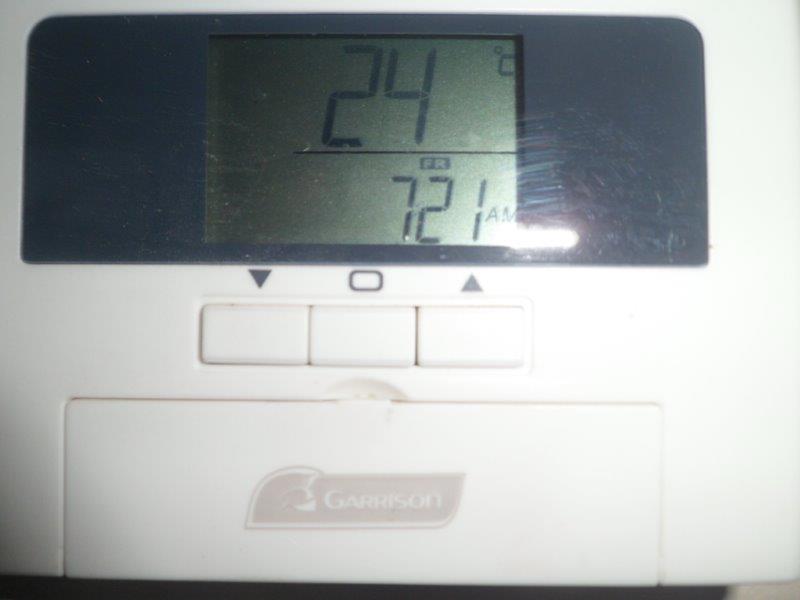

The heated water was originally provided by a oil-fired hot water tank. The photo is the manifold supplying the tubes in the concrete. (Kitec) The temp. of the floor is 24-28 Deg. C to be comfortable. (photo of office thermostat) Thermistor remove from circuit board and place in a shallow hole drilled in the concrete.

As with the air-handler the floor can also receive its heat via the solar wall. With the future completion of the solar collector the shop could receive its daily heat requirement with the sun.

Randen