The drywall and priming is done.

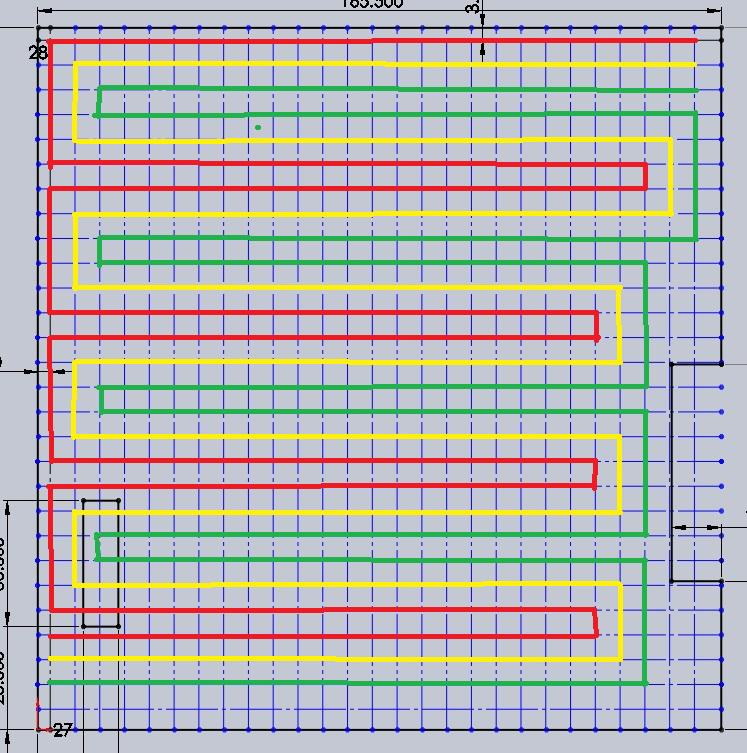

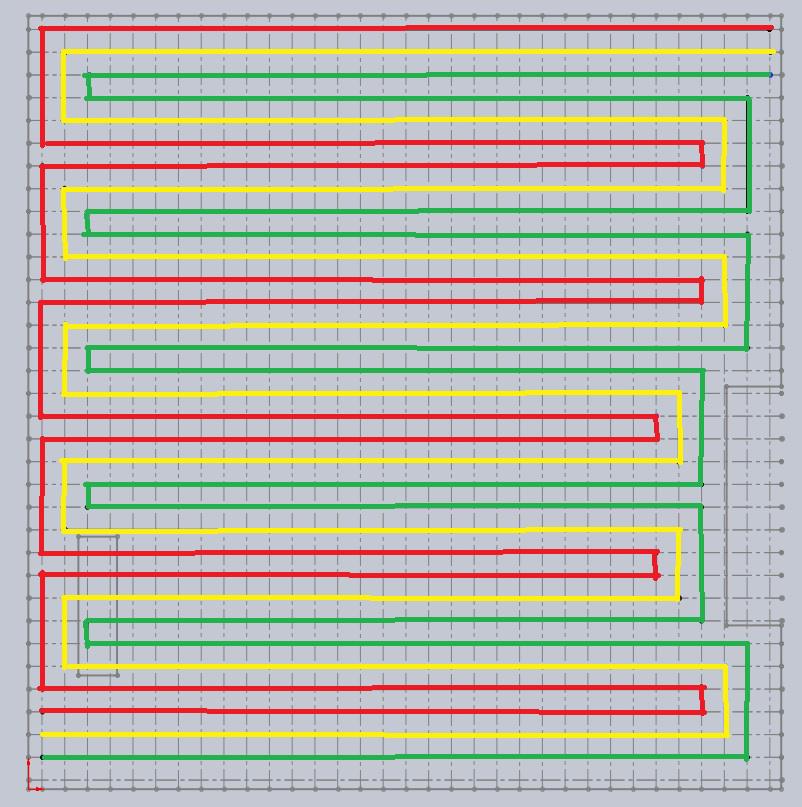

The hydronic floor work is ready to start anytime. This is the current tubing layouts I have laid out for the floor. I drew it up in my CAD software (SolidWorks). I'm looking for some feedback on which will be better and if the extra work will be worth it?

This is the easier one. The tubing is on 6" centers. Each parallel length is 1380 inches long, so flow will be equal through all branches. By using parallel runs, pumping losses should be minimized even for a small room.

Here is the second more preferred, but definitely more work. This is with 5" tubing centers. The parallel lengths are about 1720 inches each. I like this one because it really works into the irregularities of the room better. I don't see there being a huge benefit from going from 6" centers to 5" centers otherwise. My heat spreaders are 4.75" wide. I am wondering if bending my 1/2" pex tubing will be more of an issue with this spacing?

Feedback is very welcome!