I have one of these

http://www.bamboocraft.net/workshop/...eTorch-035.jpg

and a full bottle of MAPP gas. So, I can do some testing on scrap copper.

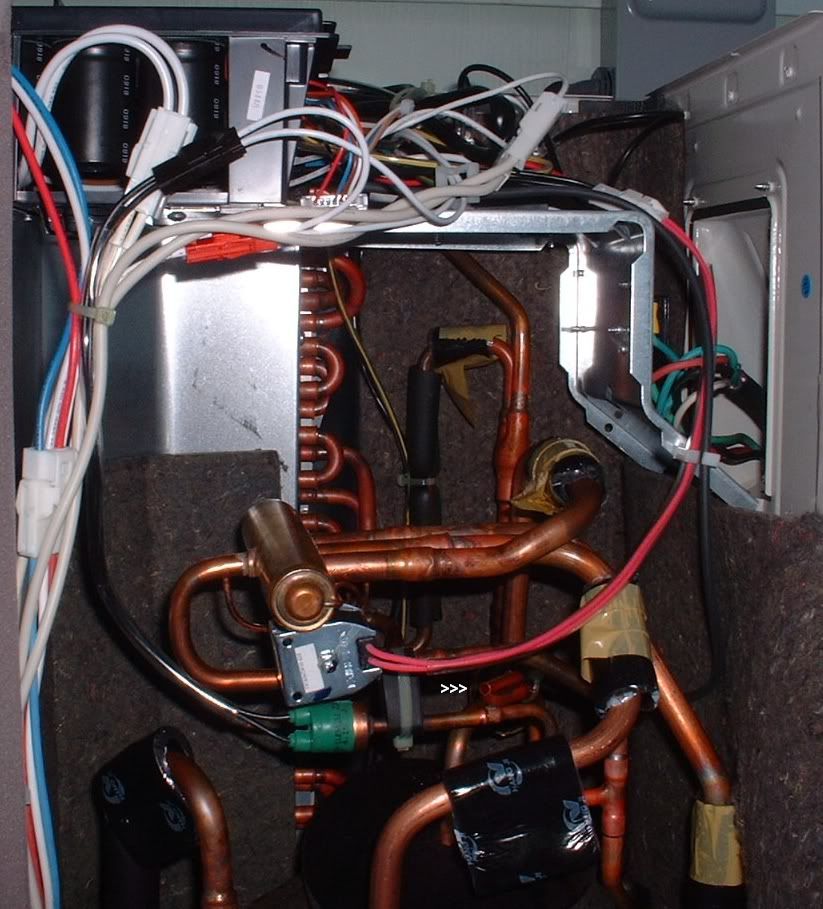

I have to pull off a short section of tube, (it held the thermistor).

And then seal up the tiny pinhole right here:

Yes, "the unit has been"breathing". I assume it's full of moist air, that's being sucked in and out of the pinhole.

This tube seems to be the output line of the compressor.

Thanks for the water bubble tip on the nitrogen flow. I'm going to need it.

Otherwise, the filler metal will just bubble right out.

Due to the hole, I will not be able to vac the system at all.

That will just pull more wet air into it. (I hope it stops raining some day)..

I've heard about protecting parts from torch heat using wet strips of cotton from old t-shirts.

I'm a bit familiar with process, due to all my DIY plumbing work..

I've watched some videos, and it seems like a really hot flame directly

on that pin-hole area would get it cherry red very quickly.

When the loose tube fell off, all I would need to do, is

quickly melt some filler on top of the leak area..

But, looking at where the leak is located, I might not be able to reach in there with the torch.

Dang! Looking at this picture, I'm really thinking seriously of trying to find a welding shop that will braze this for me..