I've been slowed down in my 'plastic planting' activities because of the need to prepare for my daughter's wedding and an arm injury brought on by too-exuberant tomato planting.

But I have been thinking about what Daox said about how much work it is to dig holes for the loop-field tubing. There's no getting around it, it is a lot of work.

I've come to recognize that debris removal from the hole is a huge part of the task. So I have developed another technique that is working very well for me...

Here is a photo of a really robust shop-vac I picked up in a thrift store for $15:

This has turned out to be a wonderful tool. If you are considering a similar approach to drilling, I totally recommend the Rigid shop vac. It is very robust and has loads of suck.

My top level (0 ft. to 4 ft.) digging method consists of loosening up the dirt the hole with a pointed iron tool, and sucking out the debris with the shop-vac.

I've calculated that the weight of the dirt coming out of the hole has been running well over half a ton per hole.

I've made up a set of digging tools with various digging tips, one is the 3 inch cold chisel and the other is the sharp end of a demolition bar welded to short lengths of 3/4 inch pipe segments that can also be used for drilling rods with my electric auger tool, previously pictured. I have 4 foot and 6 foot lengths of water pipe that I mix & match to get a proper length digger.

Additionally, I've made up a set of vacuum extention tubes from various pieces of PVC and ABS pipe. I've made two sets, one is 1.5" PVC, The other is 2" ABS.

The velocity in the 1.5" pipe is very high, and the dirt and gravel come sailing through with considerable speed. If there are any stones that are around 1.5", they will get lodged in the pipe but are easily rammed out with a 1.5" ram rod I keep at hand for such a purpose.

I made up a vacuum hose out of 3" flexi drain plastic pipe to use on the 2" ABS tool. The velocity in the 2" pipe is lower, but still adequate for the job. I haven't measured the volume of air, but I'm sure that it is higher, and debris removal is faster. The stones that got caught in the 1.5" pipe pass right through the 2" pipe, so more time is spent removing debris and less time spent removing lodged stones. The down side is that because the velocity is lower, debris doesn't move so well through the 3" flexi pipe and has to be lifted higher than the shop vac periodically to clear the line.

I've also tried 3" plastic pipe, but the velocity in the tube was too low to lift rocks.

For each of the shop vac extention tools, I followed this scheme:

- The first 10 foot length I left whole, and glued a coupling to it.

- The second pipe I cut in half, so I had a 5 foot piece, with coupling.

- The remaining 5 foot piece I cut to 2/3 length, with coupling.

- This left a piece that was in the neighborhood of 1.5 feet with coupling. I cut the free end of this pipe at a 45 degree angle and attached an illumination module to it (cheap Chinese LED flashlight, fastened on with duct tape) so I could see what was happening down the hole.

I spray-painted black paint over the coupling-and-pipe glued area, to make it easier to identify which pipe the coupling was glued to to make disassembly easier amidst all the roaring, digging and sweat (it's been upwards of 105 degrees the last few days).

On the PVC set, I also made one thin cut with a hack saw through the coupling and used a pipe clamp to hold the joint on strong. There's been a fair amount of swapping of pipe pieces as I dig down and all this has helped out.

On the ABS tool, I found screw-together pipe ends which worked out great.

At the upper levels, the iron digger is required, but deeper, the vacuum and just the 45 degree end of the illuminator-module pipe does it all.

The sound of the vacuum will tell you what is going on... when it has a low, even sound, everything is fine. When the vacuum starts revving up faster, it means that there is a clog. Sometimes there is a wad of damp dirt plugging things up, sometimes a rock has become lodges somewhere in the pipe, and it become necessary to remove the pipe string, disassemble the pipes and ram out the lodged stone.

Be careful to not have your face over the end of the pipe string while the vacuum is on, because an accidental separation of the pipe will make you the target of high velocity sand and gravel. It happened to me... not fun.

Wear safety glasses.

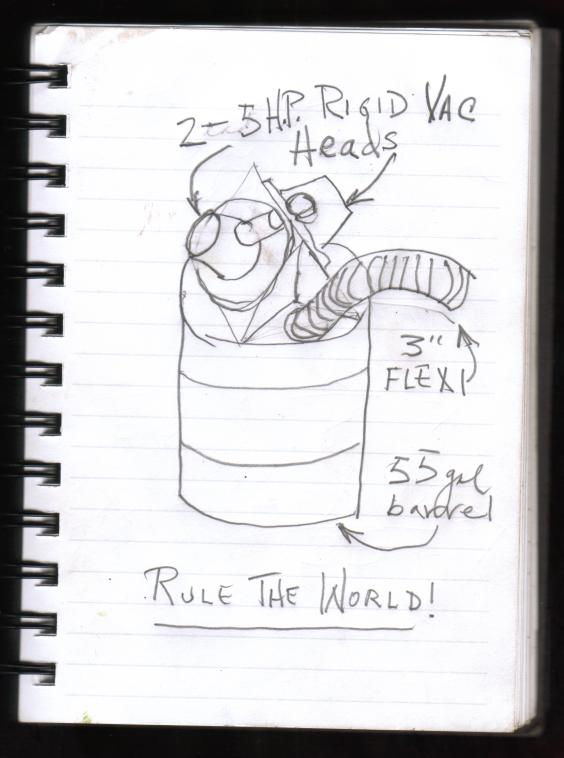

I went on a google expedition to see what was available in the way of industrial vacuums. It would be great to have a larger diameter extention tube and hose, and also a larger sized container. I was able to find 55 gallon shop vacs, but the power & volume wasn't greater than the Rigid. However, the prices sure were! Prices from $750 to $3000, way out of my league. So here's an idea that should be cheap, buildable and enable the possessor of such a device to rule the world:

Two-Headed Suck Monster

Two-Headed Suck Monster

This would:

- Hold about 4 Rigid vacs worth of debris

- Enable 3" hose & Extentions

- Have enough volume to clear large diameter lines

- Use a commonly available tank

- Be cheap to reasonable to build

...and of course, allow the posessor of such a 2-Headed Suck Monster to rule the world.

Best Regards,

-AC_Hacker