KIDS, DO NOT TRY THIS AT HOME!!!

[EDIT: 1200V are present in this unit!!!!]

Look Ma, no safety interlocks, what fun!!

Here, I have opened 'Little Buzzy' up again to see where the buzzing might be coming from.

My idea is to actually heat something with the case off and listen through a tube to try to determine the origin of the noise. I realize that the electrons might spill out all over the floor, but it's worth a risk...

[EDIT: 1200V are present in this unit!!!!]

[EDIT: 1200V are present in this unit!!!!]

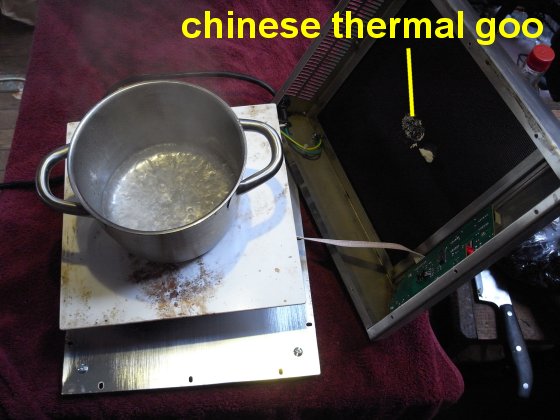

Here is the pot of water boiling merrily away, with the case off and electrons spilling out.

I don't really have a photo of myself with a tube to my ear, searching for the source of the buzz, so you'll just have to imagine it.

I did determine that the main location seems to be the induction coil itself. I really need a stethoscope with a contact tip to get a better idea of exactly where the sound is coming from.

[EDIT: 1200V are present in this unit!!!!]

I also let the cooker go long enough to boil some water, after which I measured the temperature of the coil to be about 147 degrees F.

Not such a high temperature, which allows for the possibility of gluing non-magnetic mass to the coil.

The arrow points to the spot where the Chinese thermal goo is suppose to go, just below the main 'goo-site' there is another off-center splodge of goo apparently left by some nameless Chinese forced-labor prisoner (probably in prison for dancing tango), who makes these units.

Through my dis-assemblies and re-assemblies the main goo-site is mostly empty, so I redistributed the orphaned splodge of goo carefully over the main 'goo-site', being very careful to rub it into the cooking surface smoothly and evenly.

Then I re-assembled the unit and tried another temperature test, allowing 10 minutes between temp change and measurement...

[EDIT 4/12/2013: My first temp measurements allowed 10 minutes between tests. Turns out that it takes the unit longer than that to 'settle', so I did another series of measurements and allowed 30 minutes for the temps to settle. Results below are "Measured#30"]

Nominal Measured#10 Measured#30

140F 140F 152F

150F 150F 162F

160F 160F 170F

170F 170F 182F

180F 175F 190F

190F 192F 205F

200F 200F

210F 207F

Well now, let's hear it for the beneficial effects of careful splodge dispersion! I would imaging that had there not been that random bit of splodge, I certainly could have used CPU heat sink compound.

I have not yet solved the buzz problem, but I certainly have improved the accuracy of the temperatures.

[EDIT 4/12/2013: It looks like I didn't solve the temperature accuracy problem at all. In fact it looks like the algorithm that is used to control temperature is not a PID algorithm, as PID would have a much faster "ramp-up"]

[EDIT: 1200V are present in this unit!!!!]

Best,

-AC