Looks like this is the place for this so here I go. If you are going to be drilling a well, by far your best choice to power your drilling platform would be a nice gas motor in the 4-8HP range which has its high RPM's geared down to produce high torque. For some people here though, having a nice reversible electric motor can bring with it some nice benefits such as noise level and reversibility which is a boon in attaching and removing drill pipe extensions. Also since this is EcoRenovator, why bring another gas engine into it

Before I get into electricity stuff, let me caution that my degree is in chemical engineering so my electrical engineering skills are a tad rusty, please feel free to correct anything that I don't get quite right here.

So after much research there are a few good sources for electric motors with similar power ratings to gas, electric vehicles and treadmills. Motors for vehicles tend to be rated for the 12-24Vdc range as they are going to be run off of lead acid batteries typically, this means that for high power loadings, they are going to require very high current. 1HP is ~=750W so a 1HP motor is probably drawing ~800W from the batteries which at 12V is almost 70A! If we're going to power this off the wall outlet the power supply becomes non-trivial at these kinds of loadings.

Treadmill duty motors on the other hand are normally designed to be run using ~130Vdc which makes it very easy to just run AC current out of the wall through some form of rectifier and power the motor directly. On top of that, treadmills and most other exercise equipment have the tendency to be used for a few months or so only to be forgotten and shoved into the corner when that good old American laziness sets in and there is normally a very nice selection in your local "for sale" section.

And now here's the one I recently picked up.

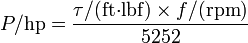

As you can see, I've found a 130Vdc motor that has a full speed of 6700RPM at at that speed draws 18A and puts out 2.5HP. Below is the conversion of horsepower to torque

From this we can see that at full speed, this motor is only putting out ~1.96 ft*lb of torque which is far too low for drilling. But if I were to gear this down at 60:1 we're now up to almost 120 ft*lb of torque at ~110RPM. That much torque will move some dirt and rocks.

Now for the other components of my haul

Power control board

Toroidal AC choke

sliding potentiometer

Here's a schematic of the layout

http://www.instructables.com/files/o...NMFMEG9UME.pdf