I was getting pretty desperate trying to get some welding done a few weeks back. My 2 HF wire feed welders refused to weld any more than 2 minutes at a time before shutting down. 102 degF temperature didn't help much either.

The 170 amp one was the newest. I bought it because the old 110A unit would shut down in 2 minutes in 50 degree weather. After blowing most of the dust out of it, there wasn't any change. The 220V fan was pumping plenty of air. I took the cover off 10 minutes after the shutdown. The copper windings were about ambient temp but the transformer and inductor (on top of the transformer) were really warm. There was a heat sink from an old computer handy so it got a new home on top of the inductor with a flat smear across the face and mashed on hard with Plumbers Goop! That small addition was worth an additional 2 minutes. Still not good enough.

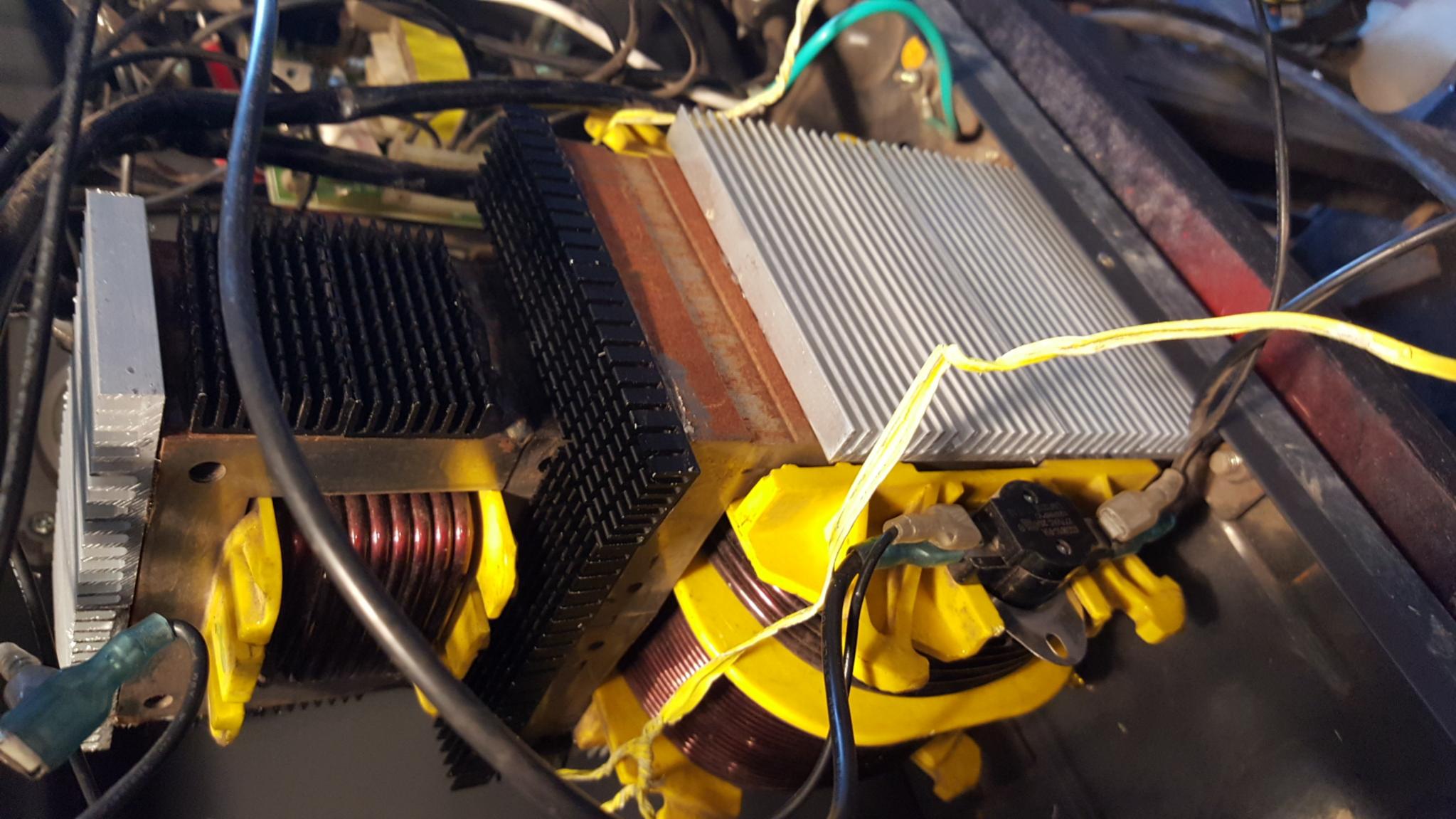

The old 110A welder was expendable so it got redecorated with $30 in heat sinks and a more powerful fan off ebay. It welded better than it had ever welded before. I welded for half an hour non-stop without any shutdowns. Yesterday, it was 98 degrees and it welded for three hours with a few 5 minute breaks and to change the wire spool. Who knew?

Two of the photos are turned 90 degrees to the side. I don't know what happened but maybe everyone can see what I did to get greater than 50% duty cycle from their welders.