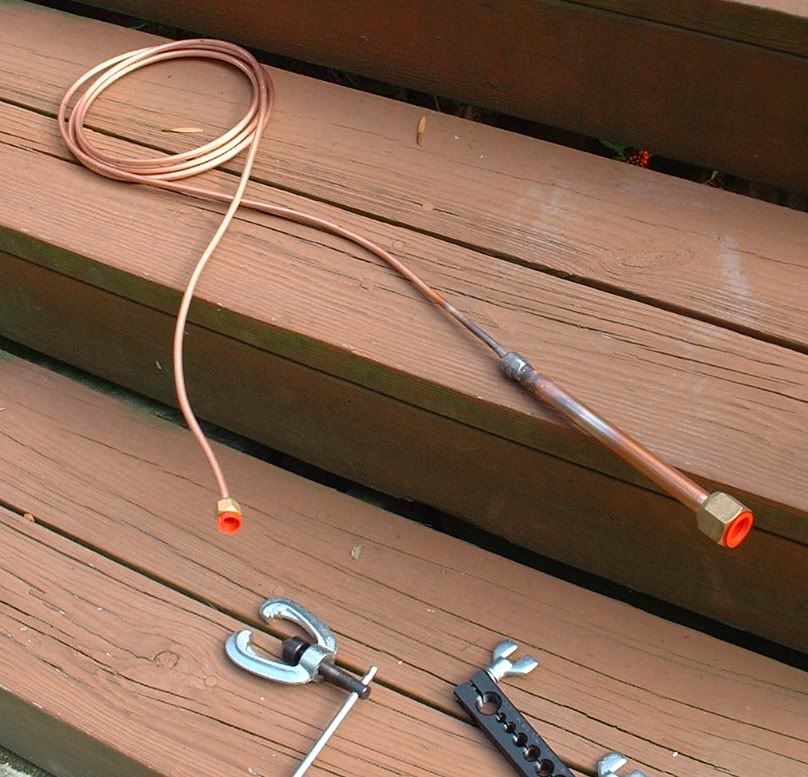

I was letting a little CO2 into the 1/4" end as I was brazing the cap and pipe end.

Using the Flare tool on the 1/2" end too (actually 0.625")

I don't know what I'm doing, but the flares seem to be holding okay.

Finished product.

Only, I left a tiny void in the bottom of the 1/4" hole.. Had to go back and re-do it.

When using high gas flow to the torch, the copper heats up quickly.

The filler metal can actually melt really fast.

I'm starting to get the feel of how the melted filler moves and reacts to the heat level.

It seems like being a slow learner, isn't helped when you get old..

Anyways, the test loop is installed on the Sanyo and the system+loop is holding 400 PSI now.

This week (if things go my way), I will bleed down the system and start

making some vacuum checks.