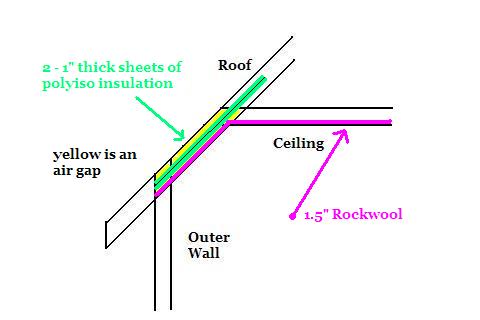

This is what I ended up doing with the first half of the attic. The bottom of the angled area has about 1.5"-2" of rockwool in it (~R-3 per inch). I slid in two sheets of 1" thick polyiso insulation above it (R-6.5 per inch). This will give me a combined total of roughly R-18. Nothing amazing, but that is about as best as I can do with the hard access to the area. Using the foam boards also allowed me to leave a 1" gap above the foam as an air passage for venting. They also extend far enough up to act as a dam for when the cellulose is blown in.

When winter does decide to come around, I'll measure the wall temp and see how cold it gets. I have one of those IR temperature guns. If need be, I'll add another sheet or two of foam board on the inside of the wall and drywall over it.

Next on the list is adding in the cellulose. That'll really pump up the r-value. I'm planning on blowing in roughly 12" of cellulose over the existing rockwool and fiberglass. This should get the r-value for the rest of the attic up to about 60-65.

Insulation diagram.

Fitting and cutting the foam boards.

Installed foam boards.