Hi all, I've been contemplating building a few flat-plate solar heat collectors for a domestic hot water and in-floor heating system I hope to build quite soon. There's some directions over on builditsolar that show how to build something with either PEX or copper pipe bonded to 6" aluminum flashing roll with silicone, stapled to a plywood back-plate. Link:

The $1000 Solar Water Heating System This all gets mounted in an insulated box, and glazed with polycarbonate sheeting.

Kudos on the design, however the silicone joining the collector plates/fins can't transmit heat very well, and a metal-to-metal bond would be better. Commercial $1000+ flat-plate collectors usually have a copper collector fin or sheet welded to a copper pipe somehow, thus achieving much better thermal conductivity.

Then there's the cost. A 6" x 50' roll of aluminum sheeting is $20-30, where the same thing in copper is more like $120-150. As for attaching the cheaper aluminum sheeting to the copper pipe, I've found a way to braze them together, but the process is *very* tricky and often results in melting through the thin aluminum sheet rather than getting a good bond. Also, the brazing rods retail for $5 for two 10" rods. Cha-ching!

All-copper? If I buy copper sheeting instead of the cheaper aluminum, I could just solder the sheets to the pipe and have a wonderfully conductive length of plate collector to paint black and install in my glazed box. I also wouldn't melt through anything and make holes and extra work for myself.

Concentrating collectors... After some research, a concentrating collector would be better for me, as I live in a cold winter climate (in Ontario, Canada). I'm trying come up with something in between a cheap flat-plate design and a more costly concentrating collector.

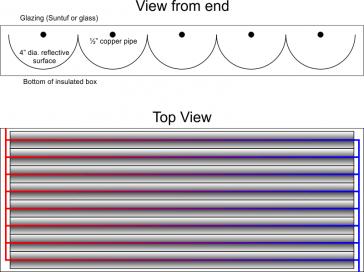

Here's a drawing of what I was thinking of:

Basically, I would use cut-in-half sections of 4" PVC pipe, lined with something reflective, with 1/2" copper pipe, painted black, suspended above the curved, reflective surface as in the drawing (end view). My hope would be that the pipe soaks up as much of the direct and reflected heat as possible, and gets much hotter than just a plain-old black plate would get, especially on colder days.

Any thoughts on my approach?

I think the design might work, but I'm not sure what to use for a reflective material. Custom-made glass/mirror seems absurd for a cheap DIY project. I thought about using polished stainless steel sheeting, but it's difficult to get, hard to keep shiny when you work with it (scratches easily) and costly, although almost mirror-like in reflectivity.

I almost think that the cheap 6" x 50' roll of unfinished aluminum might do the trick, if I can get it mounted cleanly to the inside of the 4" pipe (which is basically just a form) and maybe polish it up a little.

Is this crazy, or crazy enough to work?