Hey now! Mike wins.

It looks to me that the previous owner ran this baby nonstop and didn't clean the filter. Once the filter clogged sufficiently, the trap was set. The motor quickly heated up and heat cycled for a long time, and toasted its sleeve bushings. Not enough to seize up, but enough to cycle on its heat overload and draw way too much current.

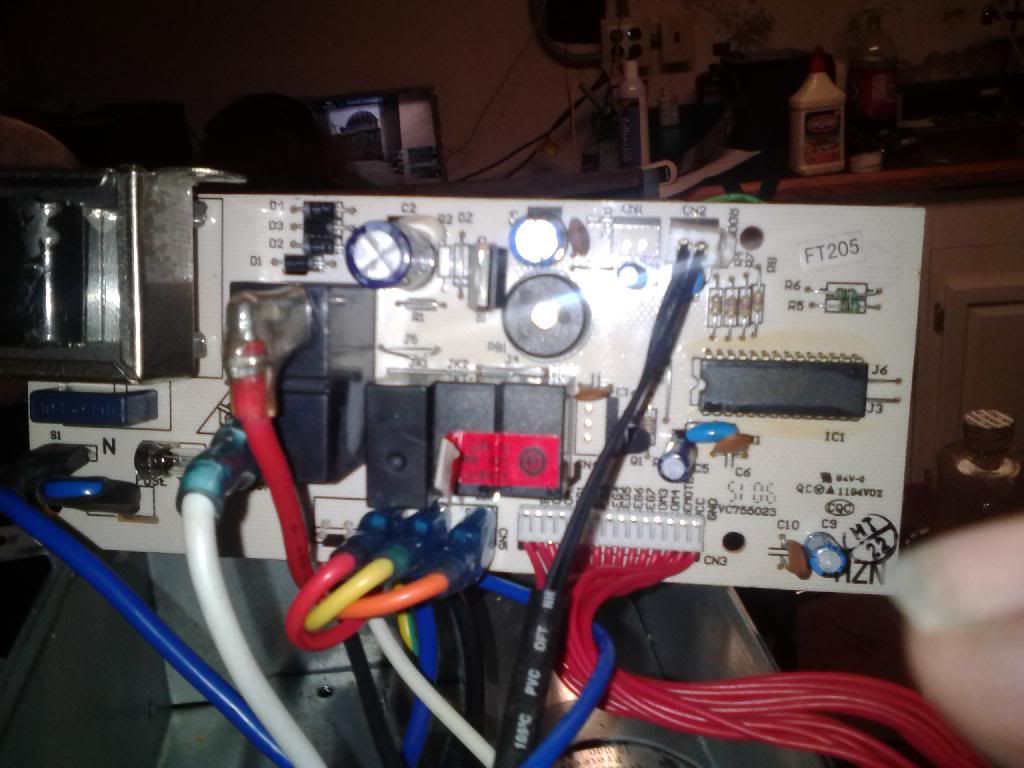

This lack of maintenance dominoed all the way to the digital switch chip. The motor tried to draw excessive current through the itsy-bitsy sugar cube relay. When it died, it shorted all its parts to each other. Its contacts tied together, causing the fan to run constantly. The coil shorted, killing the high speed fan switch. Luckily, the rest of the IC survived, and the mayhem didn't make it to the micro.

When I pulled the high speed fan relay, the short through the IC output remained. However, the remaining switches in the IC still worked. Like usual, the manufacturer didn't fully utilize the IC, so it had extra unused switches in it. So, I rigged the high speed relay to another switch. For wire, I harvested an old phone cord.

input on left:green wire jumped to micro. output on right: red wire jumped to relay, trace to original output cut.

To find a replacement for the dead sugar cube relay, I went into the shed and found something dead. These things are in everything with digital controls nowadays: cable boxes, space heaters, fans, dehumidifiers, crt monitors, etc. I recycle my electronic waste, it's better than radio shack nowadays. 90% of the rest of the world doesn't throw away items of value because they need repairs, so why should I? If I can't use or cannibalize them, I trade junk with someone who can.

Can you tell which cube I replaced?

So after some micro-tiny soldering with a magnifier and my regular sized iron, I moved on to the root cause. The filter got a shower while I found my sewing machine oil. I love that stuff because it's thin and penetrates like WD-40, but remains. Plus it's in a bottle with a retractable straw that will fit WAAAY down in between tight things (like a window a/c fan motor) without dripping oil all over everything or dismantling the world to get to it. I applied a generous amount (ten drops or so) to each side of the motor, spinning the shaft a few times along the way, until it felt very free.

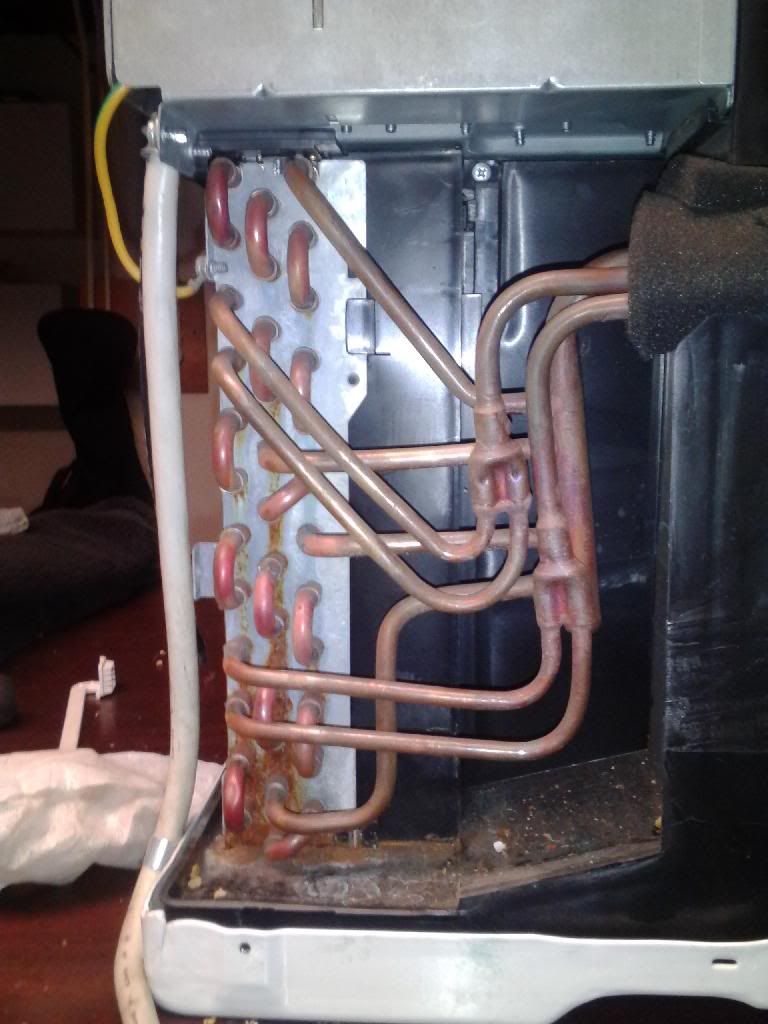

I let it sit for a while so the oil could penetrate, while I did a visual inspection on the rest of the unit. One thing I noticed immediately is that although the heat exchangers have more surface area than older, vintage units, the tubing is smaller and spaced closer together. As a result, they are thinner and lighter. They also have more elaborate circuitry than the old ones did.

evaporator - 4 circuits

condenser - 2 circuits that merge at bottom

After finding the vent lever in the blower cavity and snapping it back onto its post, I plugged it in and turned it on. Now it works perfectly. I'll take some measurements tomorrow.