the first unit I experimented with was an ancient dehumidifier. It probably looked like this during its younger years:

Now it looks nothing like this. It has been experimented with in multiple ways, but still retains its original charge and plumbing. The covers have all been either tossed out or harvested for the sheet metal. It's ugly, but it still works.

I learned pdq that these units were designed to distill water out of the air by chilling the evaporator coil to just above freezing at room temperature (about 65 degF or so). Even at that temperature, if the unit runs a long time the coil will frost up and freeze. Below about 60 degF, the evap coil will form frost in 15 minutes, then freeze as fast as it can pull water out of the air.

The units have a built-in frost sensor to detect when the coil has loaded with ice enough to choke the airflow. While warm air is flowing through the evaporator, the refrigerant picks up heat from the air and comes out above freezing temperature. Once the air path is clogged, the refrigerant cannot pick up much heat and leaves the evaporator below freezing temperature.

defrost thermostat is part #25

The sensor, named a defrost thermostat, is wired so that it opens the circuit to the compressor when the refrigerant line leaving the evaporator falls below a certain temperature. During this condition, the fan runs to assist thawing the frozen heat exchanger. Once the evaporator has thawed, the thermostat closes the circuit and the compressor starts again. This cycle is repeated until the humidistat is satisfied or the unit is powered down. This is known as "passive" or "warm air" defrost.

The strange thing about these "old style" dehumidifiers is that the defrost thermostat was not included in the less expensive models. These "economy" models simply ran and ran, forming a solid block of ice inside them. Obviously, this method isn't very efficient. That's why a lot of them didn't have finned tubes, but just a bare coil. That way, air could still flow around and through the iced up evaporator and draw more water out of the room air.

The defrost thermostats used in these units can be (and are) installed in window air conditioners and heat pumps to provide the same functionality. They are dirt cheap, and come in a wide range of "make/break" temperature combinations. They were widely used in refrigerators, freezers, and heat pumps until digital control boards superseded them.

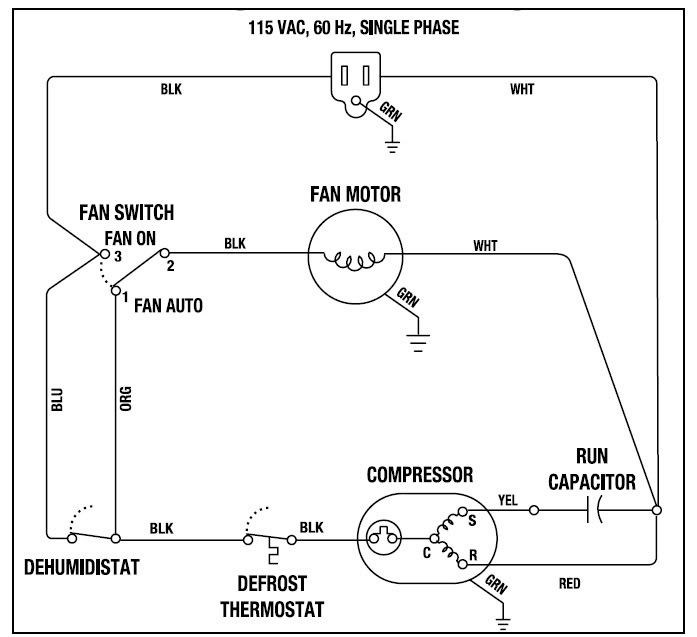

Here's an old schematic:

Old school air conditioners were wired the same way, except they had a thermostat control where the dehumidistat is in this diagram. The defrost controls can be wired in the same exact way. The low-temperature range thermostats are the best ones to use for this purpose, with around 25F break, 45F make contacts. The 25F break temperature ensures that the coil is frosty, but not frozen solid. The 45F make temperature ensures that the unit will still run when temperatures drop. Of course, below about 50F outdoors, the unit may take forever to come out of defrost.

a DT45 thermostat (described above) sells for $3 on ebay:

http://www.ebay.com/itm/DT45-Refrige...item2342626452

Usually, these buggers are described by their upper limit temp (DT45) or by both upper and lower limits (L70-58F or L70/58). Sometimes, they are numbered by their upper limit and difference (L72-25). If the number has a WR in front, the numbers mean nothing as to temperature ratings. Regardless of how they are numbered, you can easily look up specs on these devices via google or bing search.

If you want to run a passively defrosted unit near freezing temperatures, the airflow through the evaporator will have to increase significantly. In most cases, it is a losing battle with air-source units.