I would like to thank AC Hacker for his thread on Heat pumps. He pulled back the curtain of the magic in the vapor compression machine. It inspired me to try my hand at a DIY Ground source Heat Pump. "The Homemade Heat Pump Manifesto."A heart-felt thanks for all your work involved with your thread.

In the true recycle reuse mantra of a DIYer my first version of heat-pump was made from items from a scrap heap. The compressor was from an old air-conditioner outside unit. The compressor was a replacement under warranty so it didn't have many hrs. on it.

The copper used in fabricating the shell and tube HX was the 3/8 line that carried the furnace oil to the old condemned furnace with a length of 7/8 You can clearly see in the photos the coil around the compressor. This makes up the condenser.

The evaporator was made in the same fashion only with two copper tubes inside a plastic hose. The hose is commonly used for hot tubs.

Most all components were recycled very few purchased. This way if it failed miserably I was out very little. But if it worked out well I would be very much ahead.

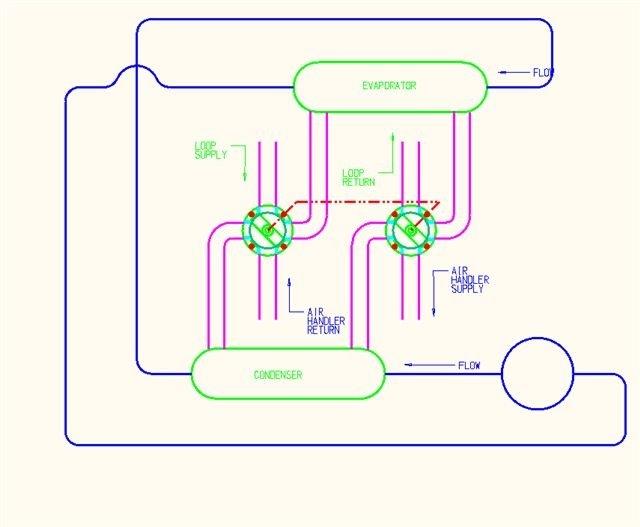

The reversing valve was a bit of work as I have access to machine tools it made this possible however the same can be done with a group of ball valves. I had thought of this route but the stainless widget won out. The reversing valve allows that the coolant is always running counter-current to refrigerant flow. Hopefully to capture a little more efficiency.

The first version had the capillary tube for the metering device.

The refrigerant of choice is BBQ propane. It seems to work well. As seen in the photo I tested the unit with water in garbage pails. It offered a good COP by calculating the heat gained and electrical energy used.

The new GSHP was placed in service but this 2 ton was un-able to meet the heating demands of the shop. In retrospect I believe the DIY HXs caused the lack of performance. If anyone is to follow:

GET Brazed Plate Heat exchangers.

In weather that was -5 Deg. C. the little thing done quite well by keeping the shop at about 18 C, but when the Canadian winter wind of -20 C showed up the toolmaker practically froze in the shop. Running flat out 24-7 we could only make 12-14 Deg.C

Although a lot of days were uncomfortable many were just fine The 2 Ton DIY GSHP proved a point.

It can be done. and the cost for heating the shop was extremely small. The oil man used to hit me with a $2800.00 bill

for the season and with the GSHP maybe $500.00

In the first year the savings paid for the excavating and HDPE tube.

If anyone is familiar with Tim Allens Comedic work. "what do we need to do with the heat-pump??" "MORE POWER"

The idea now was to go to a larger 5 Ton unit. A surplus 3 phase compressor had show-up very reasonably priced.

However, This next endeavor was plagued with a mountain of problems. We will explore this in the next postings.

Randen