Quote:

Originally Posted by jeff5may

The wish list of functions became so enormous that both ac_hacker and I could not reel in the diversity of devices that were built by many for their own specific sets of needs.

|

When I was searching for something already written I came across a couple of examples of this problem. Some had incredible lists of proposed functions only to then die quietly when the task of writing the code began. Breaking the code into distinct modules that encapsulate specific functionality is a great way to solve the problem - just include the bits you need and ignore the rest. Using this approach you could design/build a general purpose controller.

Quote:

Originally Posted by jeff5may

Ok, so your arduino is acting as an Ethernet to rs485 bridge and a humidity sensor? Are you still using an rtos or did you switch back to wiring/python/c? .

|

Absolutely still using the rtos as it makes the whole thing fit together as nice easy building blocks. Everything is written in c and using various Arduino libraries I found on the internet to run the core peripherals.

Quote:

Originally Posted by jeff5may

What else does it do? I'm very interested.

|

I have included a start up delay and power fail restart procedure. Basically it regularly saves the current time (as it has a real time clock) and in event of a power off/on (or power fail) delays the compressor start-up if necessary. It also restores the system to its last known operating state.

Using the web setup it allows the system to be remotely controlled, overriding the digital thermostat and setting the thermostats settings. Operating mode (heat/cool), on/off, desired temperature can all be set via the web page. With the correct settings in my router I can access this from anywhere making it an iot (internet of things) device.

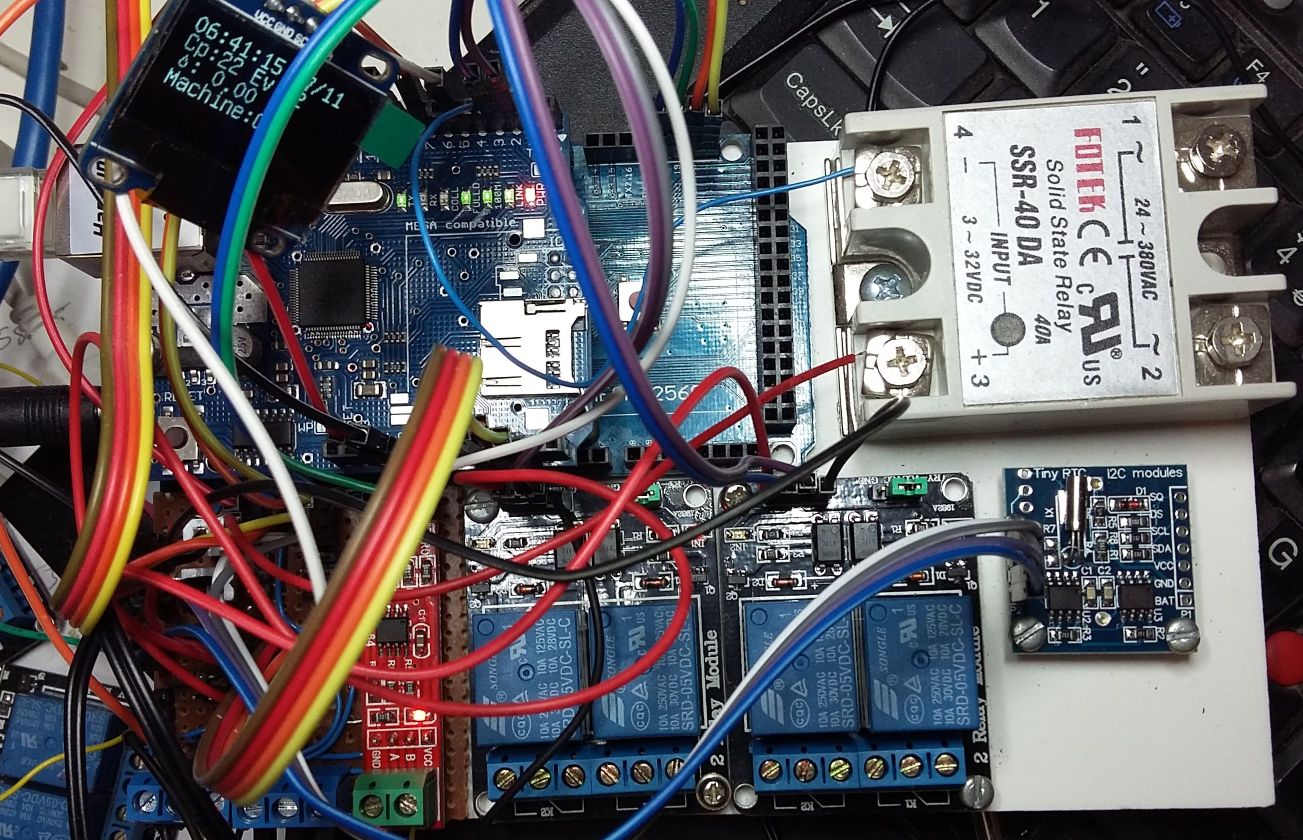

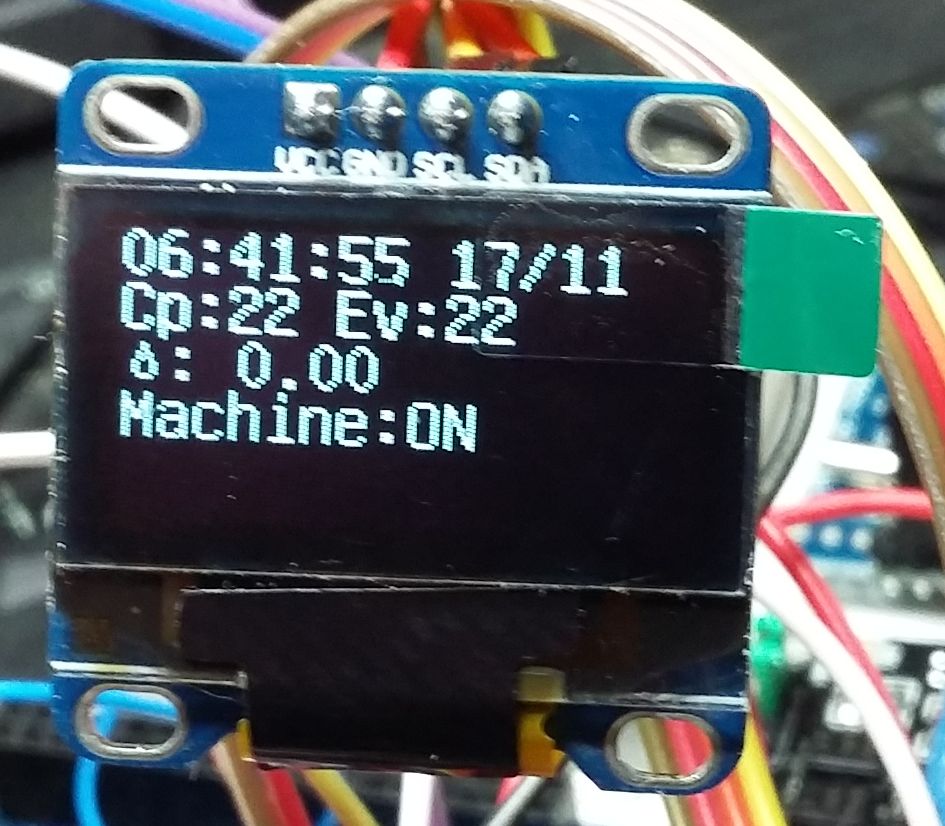

Here are a couple of (not very pretty!) pictures, one of the whole controller mounted on a board and one of the oled status display. The only bit I needed to actually build was a small board (just visible at the bottom left) that acts as a break-out board for various connections. It has the balance resistors for the NTC thermistors, screw connectors for the ds18b20 temperature sensors, the pins for the dht22 humidity sensor and several rows of common pins for vcc, ground, I2C. The small red board with green terminals is a RS485 to serial converter, the rest of the bits should be easily identified.

Acuario